Bag-making device used for full-automatic bag-making machine and bag-making method thereof

A bag-making device and bag-making machine technology, applied in container manufacturing machinery, packaging, transportation and packaging, etc., can solve problems such as melting and deformation of ordinary films, improve production efficiency and production quality, ensure protection effect, and ensure cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

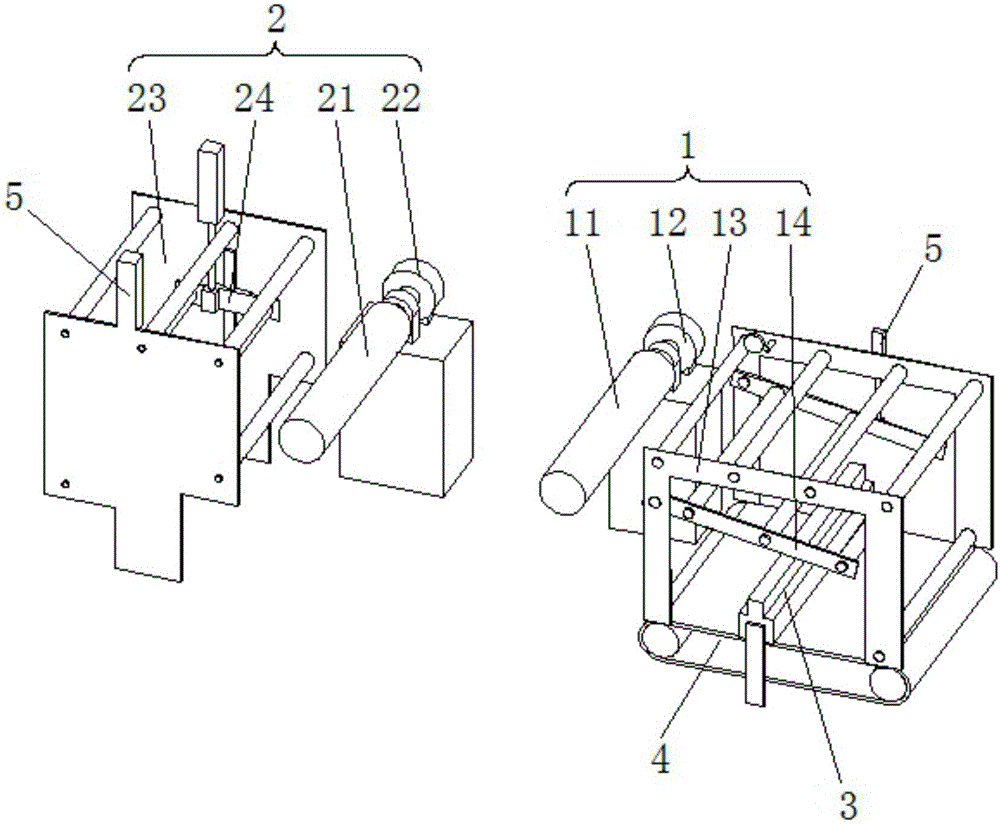

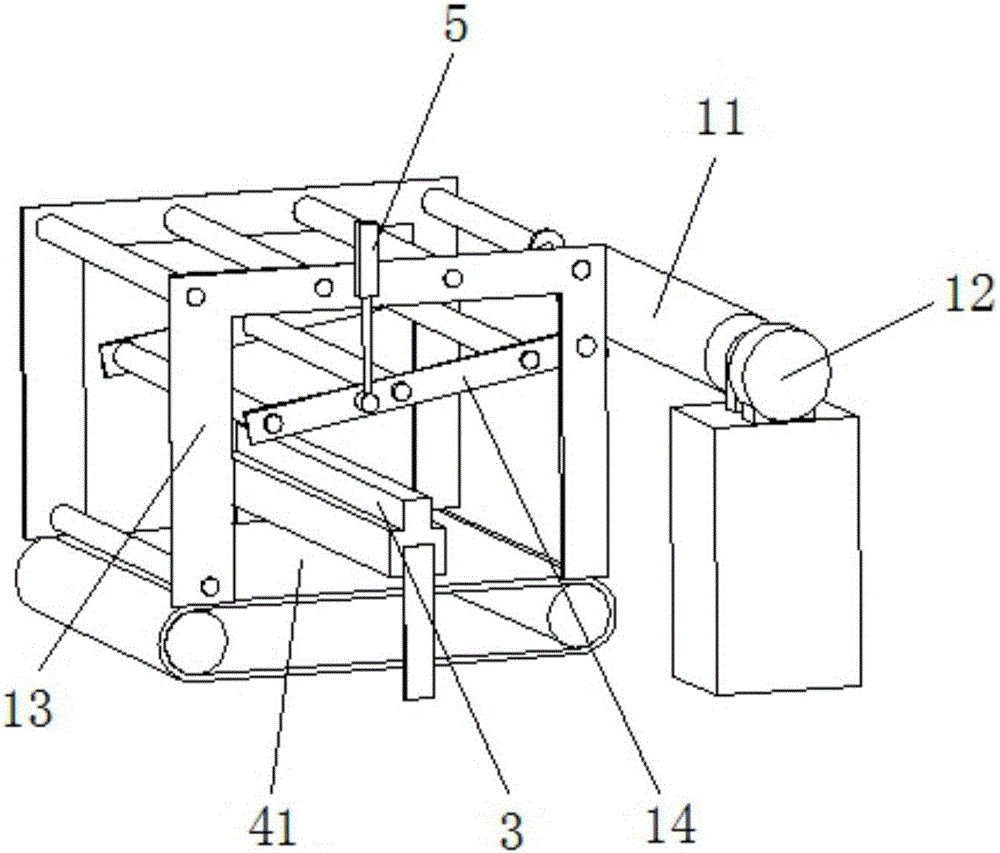

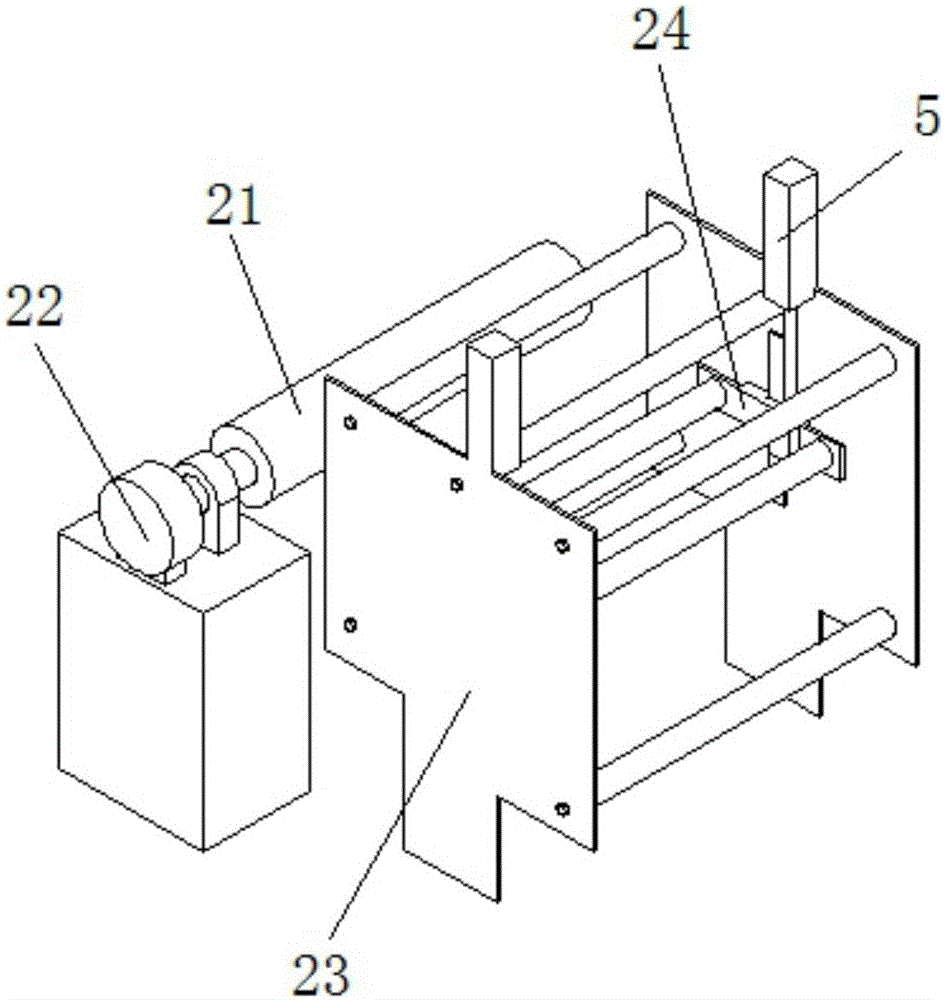

[0022] See Figure 1 to Figure 4 , the present invention includes an unwinding mechanism 1, a rewinding mechanism 2, an ironing knife 3, a protective film roll and a lower liner mechanism 4; the unwinding mechanism 1 includes an unwinding roller 11, an unwinding magnetic powder clutch 12, an unwinding machine frame 13 and unwinding floating frame 14; described winding mechanism 2 comprises winding roller 21, winding magnetic powder clutch 22, winding frame 23 and winding floating frame 24; the output shaft of described unwinding magnetic powder clutch 12 and The unwinding roller 11 is fixedly connected; the unwinding frame 13 is provided with a plurality of guide rollers; a guide roller; the unwinding frame 13 is fixedly provided with a push rod device 5, and the push rod of the push rod device 5 is rotationally connected with the other end of the unwinding floating frame 14; the output shaft of the rewinding magnetic powder clutch 22 It is fixedly connected with the rewindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com