Double-cylinder force-increased splitter

A splitter and force-increasing technology, which is used in fluid pressure actuation devices, discharge machinery, earth-moving drilling, etc., can solve the problem of increasing the radial size of the splitter, causing deflection of the axial force and affecting the accuracy of splitting. It can achieve the effect of simple structure, improved accuracy, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the drawings and specific embodiments of the specification.

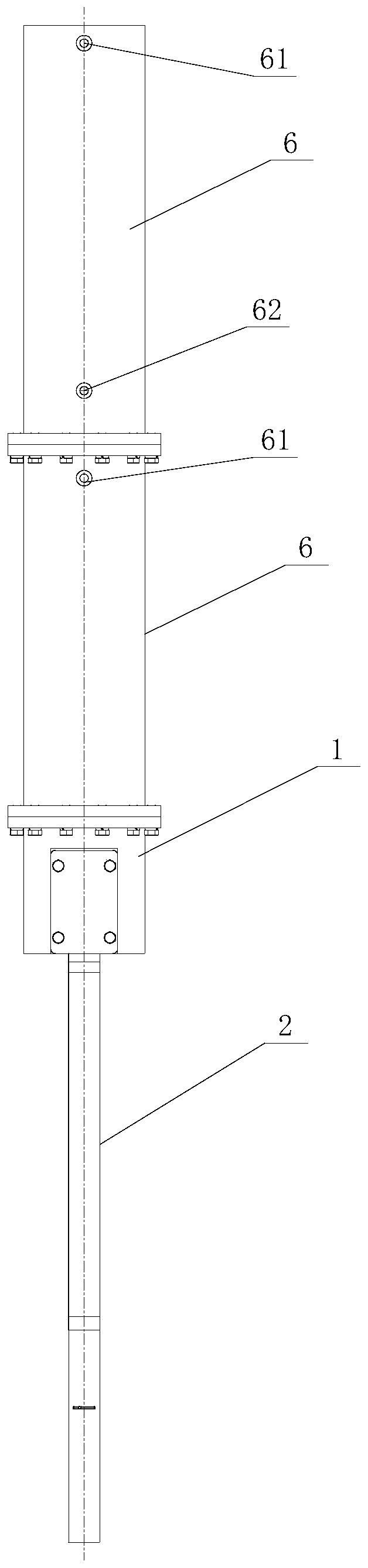

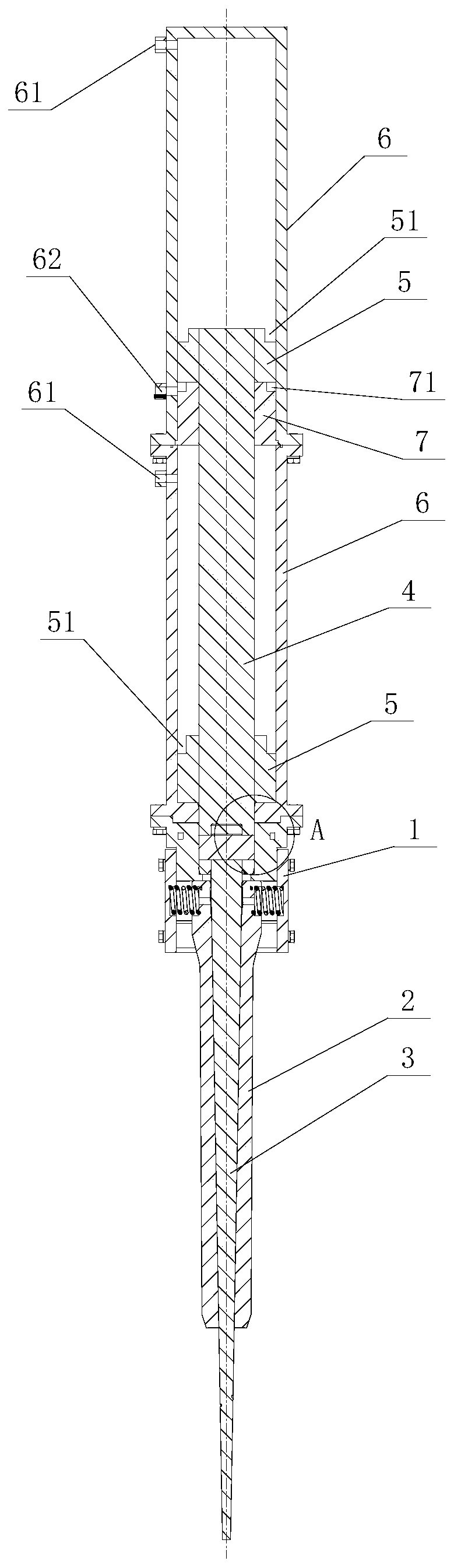

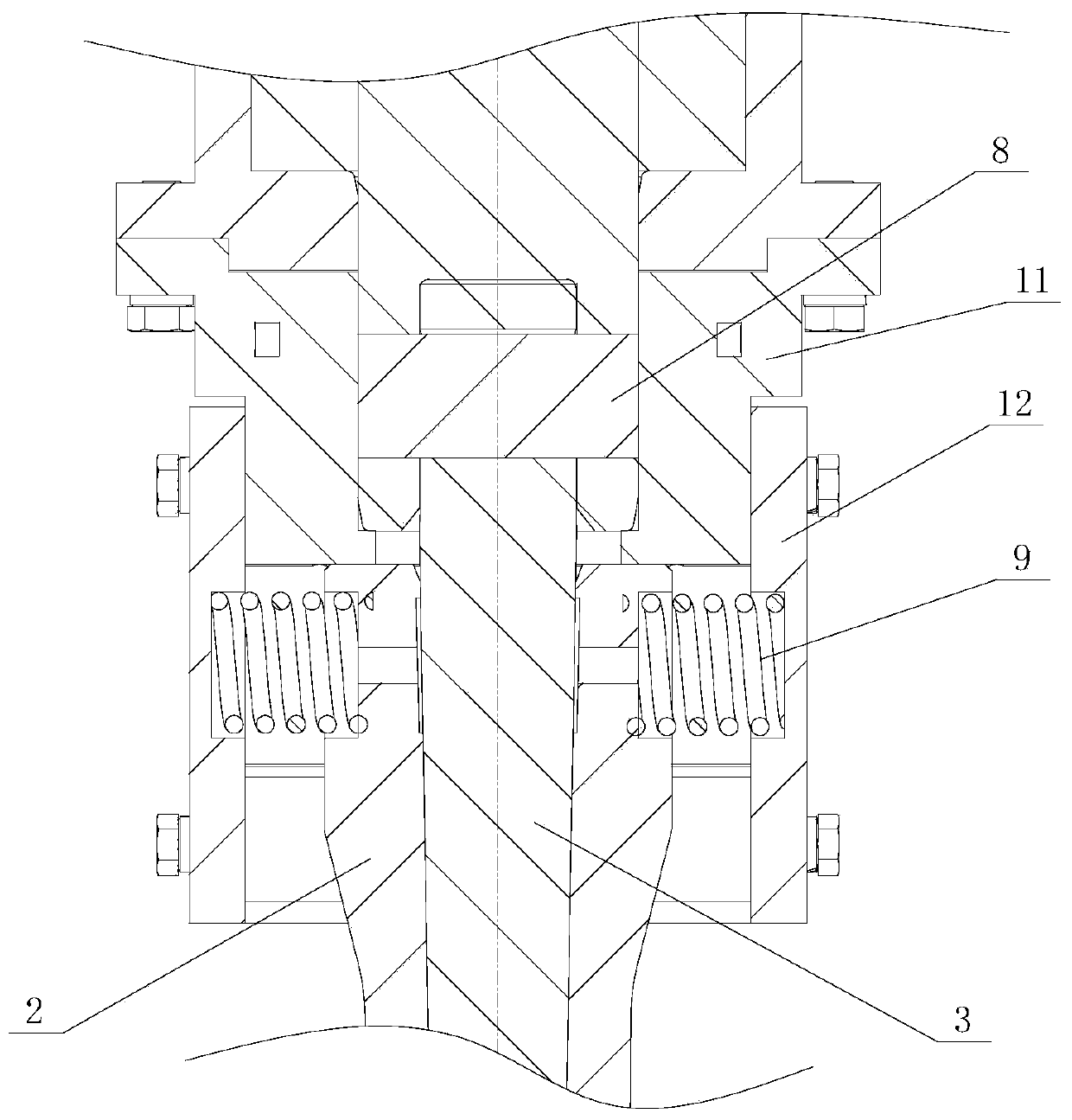

[0024] Figure 1 to Figure 4 An embodiment of the double-cylinder booster splitter of the present invention is shown, which includes a base 1, a splitting block 2, a wedge 3, a piston rod 4, a pair of pistons 5, and a pair of cylinders 6, a pair of cylinders The bodies 6 are connected in series with each other. One of the cylinders 6 is connected to one end of the base 1, and the other end of the base 1 is connected to the splitting block 2. A pair of pistons 5 are sleeved in the inner cavity of the corresponding cylinder 6, and the two piston rods 4 The end is connected with the corresponding piston 5, the wedge 3 is inserted in the splitting block 2 and connected with the piston rod 4. A pair of cylinders 6 are provided with a force oil inlet 61 at one end away from the base 1, far from the base 1 A cylinder 6 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com