Rotational flow mixing device for coal distillation furnace

A swirling mixing and coal dry distillation technology, which is applied in the direction of direct heating dry distillation, coke oven, petroleum industry, etc., can solve problems such as easy leakage, and achieve the effect of enhancing disturbance, reducing requirements and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

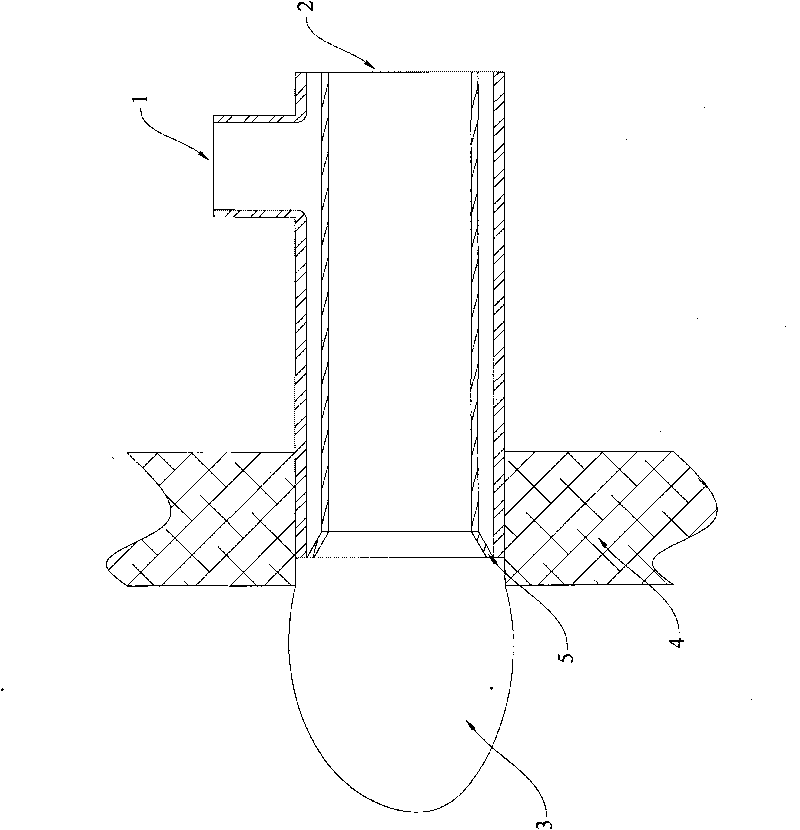

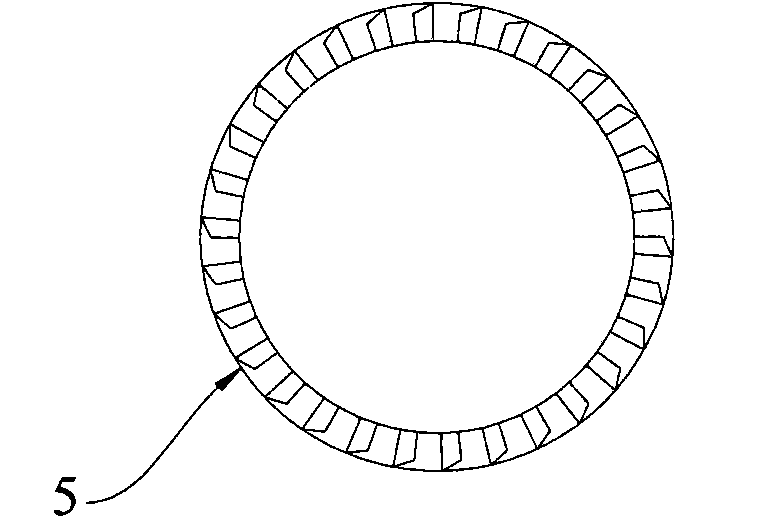

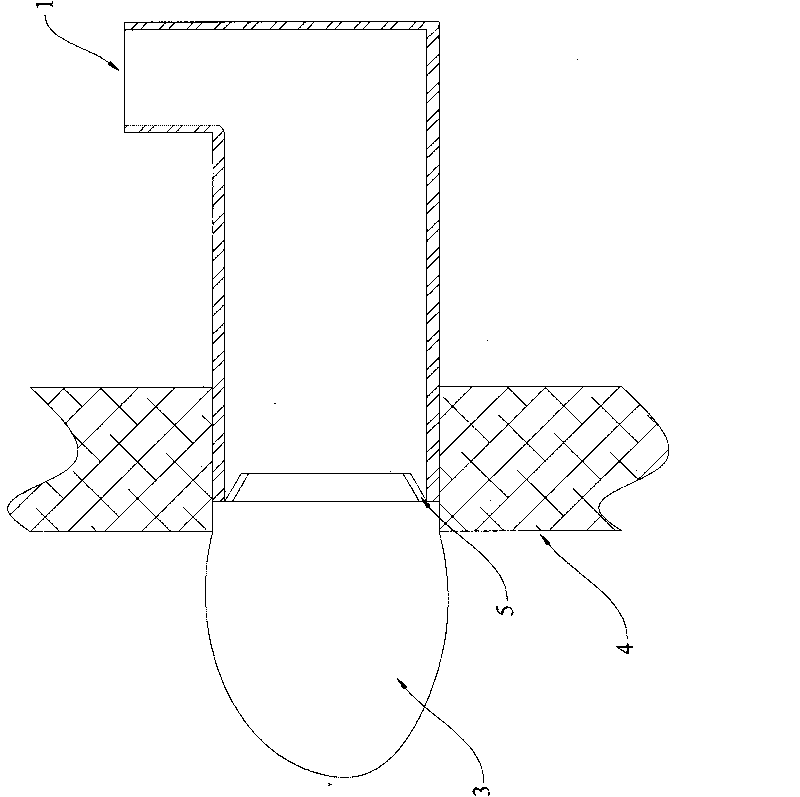

[0024] figure 1 and 2 Shows a specific embodiment of the swirl mixing device for coal carbonization furnace of the present invention, a swirl mixing device for coal carbonization furnace, comprising: a gas pipeline, which includes a cold gas pipe 1 and a hot flue gas pipe 2, wherein the The cold air pipe 1 feeds cold air into the mixing chamber 3, and the hot smoke pipe 2 feeds hot smoke into the mixing chamber 3; the swirl blades 5 are a plurality of gas outlets along the gas pipe. A plurality of sheet-like structures arranged at a certain angle to the direction of air flow in the circumferential direction; the plane where the gas outlet of the gas pipeline is located is located outside the plane where the inner wall of the mixing chamber is located, and the outside here refers to The exterior of the coal retort furnace is in the direction from the inside to the outside. Such as figure 1 As shown, the hot flue gas pipe 2 is arranged inside the cold air pipe 1 . The swirl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com