Portable field metallographic automatic grinding and polishing device and using method thereof

A portable, moving device technology, used in grinding/polishing safety devices, grinding/polishing equipment, grinders, etc., can solve the problem of inability to meet the requirements of on-site metallographic grinding and polishing, low efficiency of manual hand-held grinding, and affecting the accuracy of test results. and other problems, to achieve the effect of reducing human intervention, reducing the number of disassembly, and preventing flying out and hurting people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

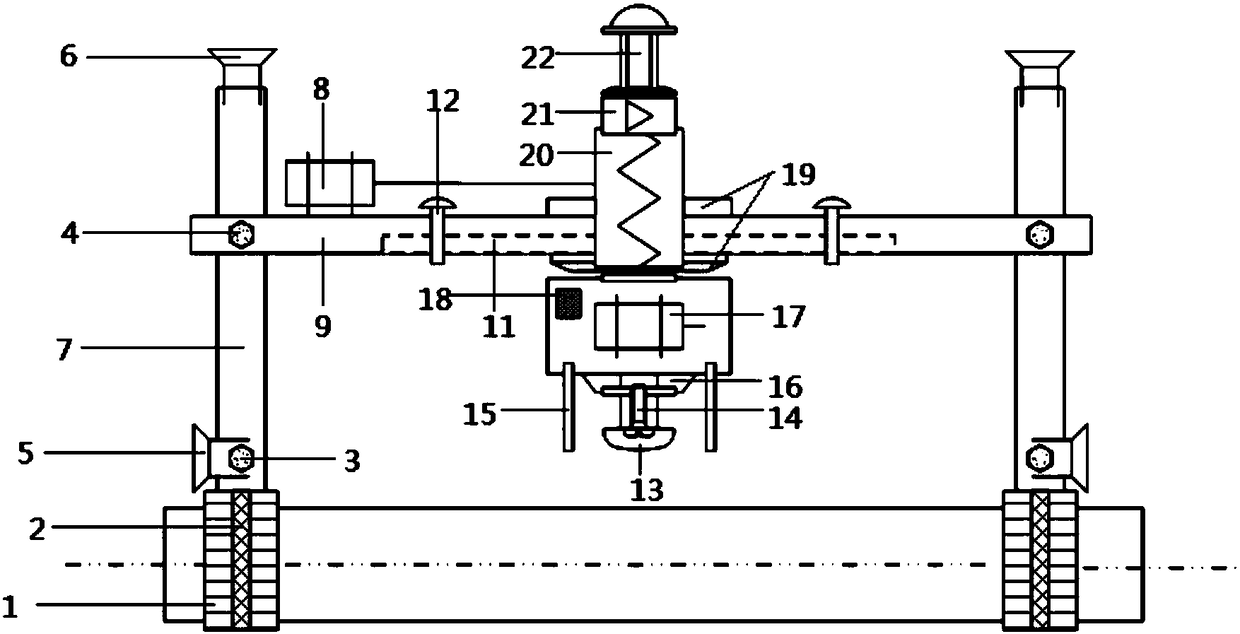

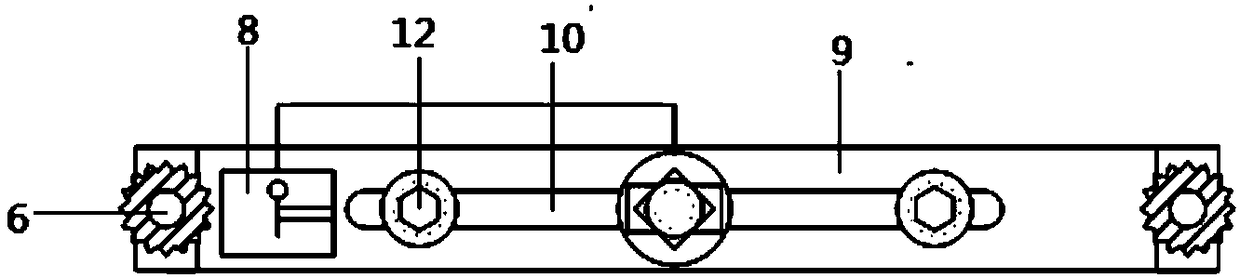

[0035] Such as figure 1 and figure 2 As shown, a portable on-site metallographic automatic grinding and polishing device of the present invention includes an H-shaped bracket, a clamping device, a horizontal reciprocating device and a rotating motion device; Rod 7, and the cross bar 9 that horizontal setting and two ends are vertically connected in the middle of two metal bars 7; Set at the bottom of the horizontal reciprocating device; when working, the pipe to be ground and polished is fixed on the bottom of the two metal rods 7 of the H-shaped bracket through the clamping device, and the bottom of the rotating device is provided with a grinding sheet 13, which is realized by rotating the rotating device. The grinding sheet 13 is used for grinding and polishing the pipe to be polished, and the horizontal reciprocating device drives the grinding sheet 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com