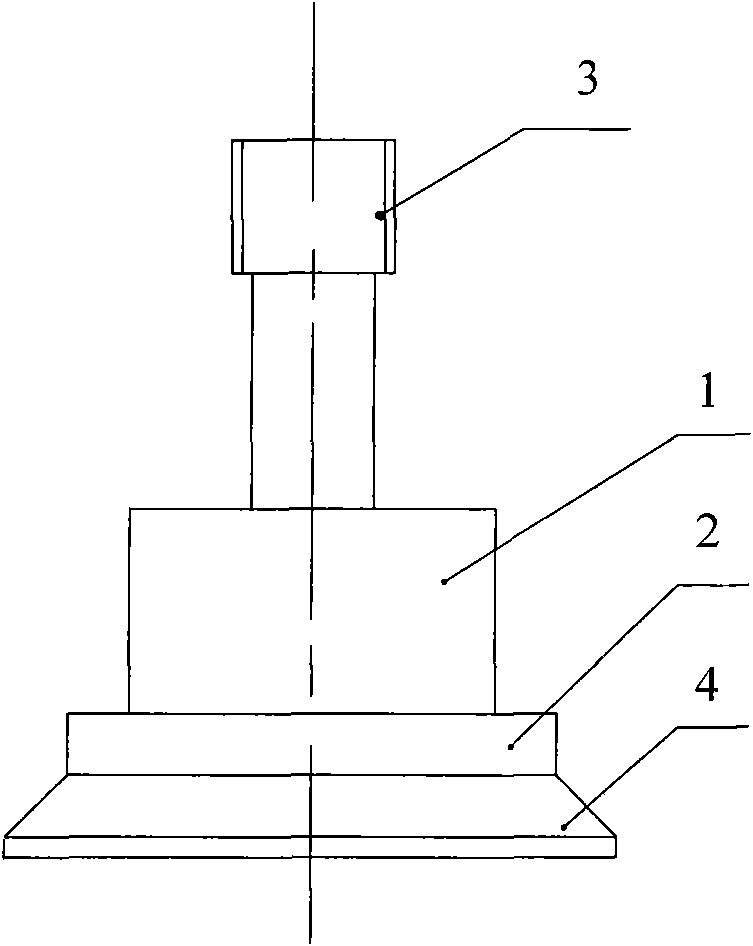

High-temperature high-pressure vacuum nozzle and sealing method thereof

A high-temperature, high-pressure, vacuum nozzle technology, which is applied in the field of autoclave forming, can solve the problems of component scrapping, loss of strength and elasticity, aging and cracking of silicone rubber plates, etc., to ensure sealing, operability, and molding manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

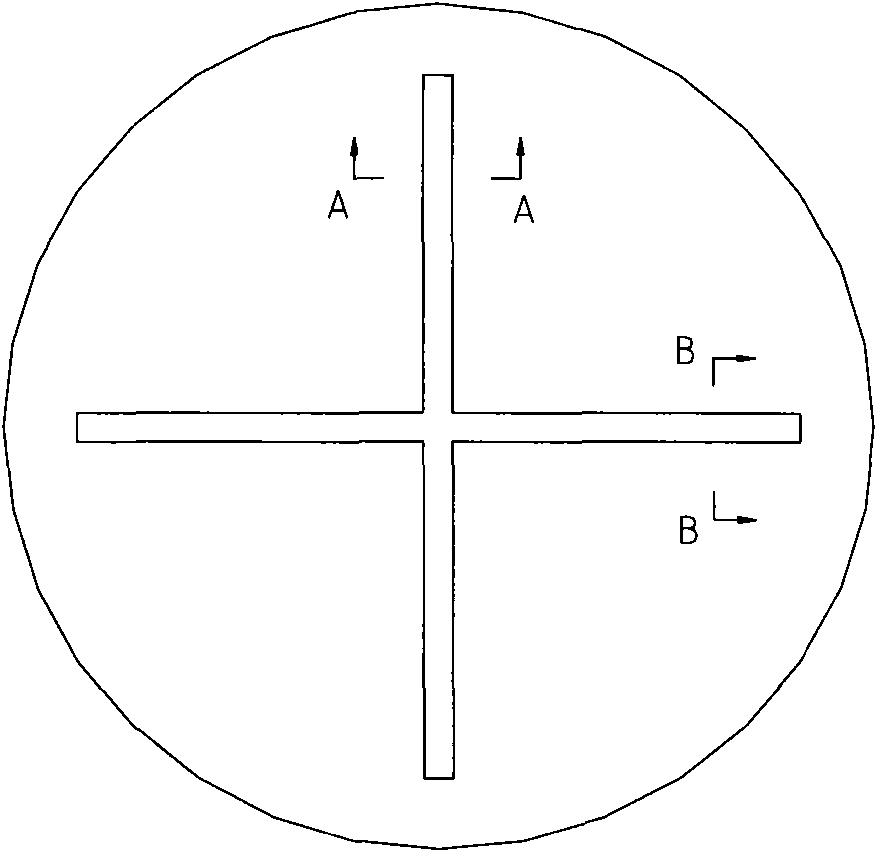

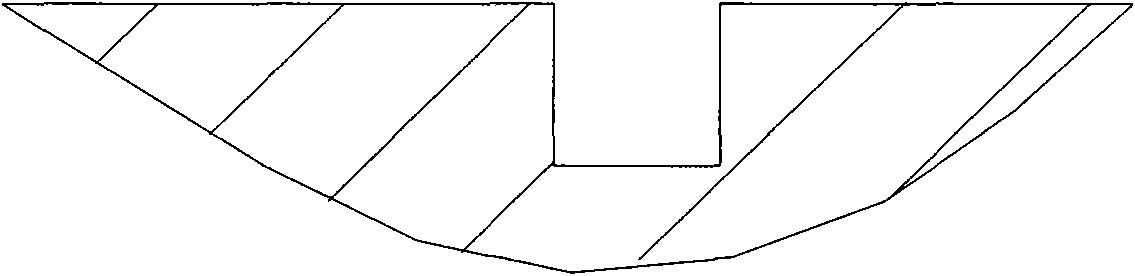

[0048] For the molding of polyimide resin-based composite materials, the vacuum bag film is made of 0.05mm thick polyimide film, and the sealing tape is made of SM5160. The base plate, pipe joint and nut of the vacuum nozzle are all made of steel Q235-A grade, and the pressure ring can be made of steel Q235-A grade. Structure selection type a.

[0049] When vacuum bag packaging, a layer of film gasket with holes is placed on the substrate, the hole diameter is slightly larger than the outer diameter of the pipe joint, and then a round hole with a diameter slightly larger than the outer diameter of the pipe joint is processed on the vacuum bag film, and the vacuum bag film is passed through The pipe joint is placed on the base plate, and then a layer of the same film gasket is placed on the base plate, and then the pressure ring is installed, and the above-mentioned parts are compressed with nuts. Finally, the reliable connection between the vacuum nozzle and the vacuum system...

Embodiment 2

[0051] For the molding of polyimide resin-based composite materials, the vacuum bag film is made of 0.05mm thick polyimide film, and the sealing tape is made of SM5160. The base plate, pipe joint and nut of the vacuum nozzle are all made of steel Q235-A grade, the pressure ring is made of aluminum 1035, and the structure is b-type.

[0052] When vacuum bag packaging, place two layers of film gaskets with holes on the substrate, the hole diameter is slightly larger than the outer diameter of the pipe joint, and then process a round hole with a diameter slightly larger than the outer diameter of the pipe joint on the vacuum bag film, and pass the vacuum bag film through The pipe joint is placed on the base plate, and then two layers of film gaskets are placed on the base plate, and then the pressure ring is installed, and the above-mentioned parts are compressed with nuts. Finally, the reliable connection between the vacuum nozzle and the vacuum system can be realized by connect...

Embodiment 3

[0054] For the molding of polyimide resin-based composite materials, the vacuum bag film is made of 0.075mm thick polyimide film, and the sealing tape is made of SM5160. The base plate, pipe joint, nut and pressure ring of the vacuum nozzle are all made of steel Q235-A grade, and the structure is C-type.

[0055] When vacuum bag packaging, place two layers of film gaskets with holes on the substrate, the hole diameter is slightly larger than the outer diameter of the pipe joint, and then process a round hole with a diameter slightly larger than the outer diameter of the pipe joint on the vacuum bag film, and pass the vacuum bag film through The pipe joint is placed on the base plate, and then two layers of film gaskets are placed on the base plate, and then the pressure ring is installed, and the above-mentioned parts are compressed with nuts. Finally, the reliable connection between the vacuum nozzle and the vacuum system can be realized by connecting the vacuum metal tube to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com