Glue injection check valve for generator end cover

A technology of generator end and check valve, which is applied in the direction of coating, liquid coating device, etc., can solve the industrial safety risks of hydrogen explosion, multiple sealants, hydrogen leakage and other problems, and achieve the reduction of major industrial safety risks and the risk of equipment damage, and the effect of improving the efficiency of glue injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

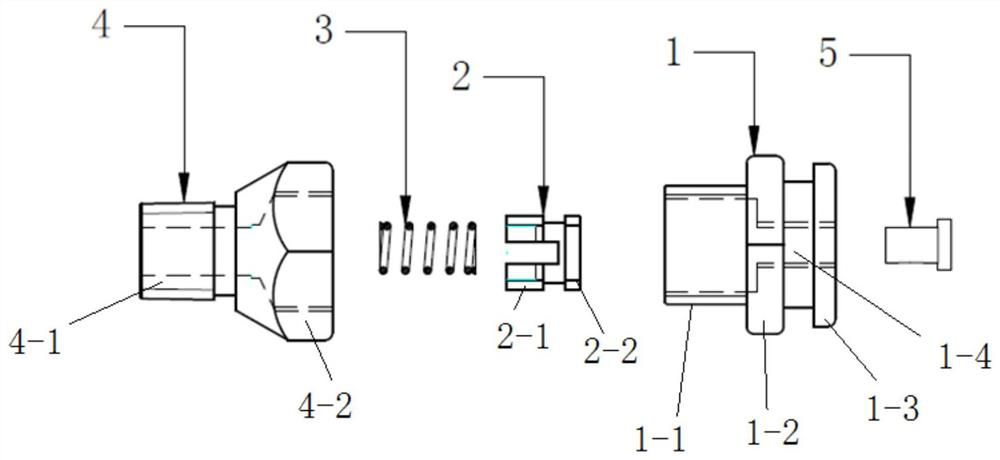

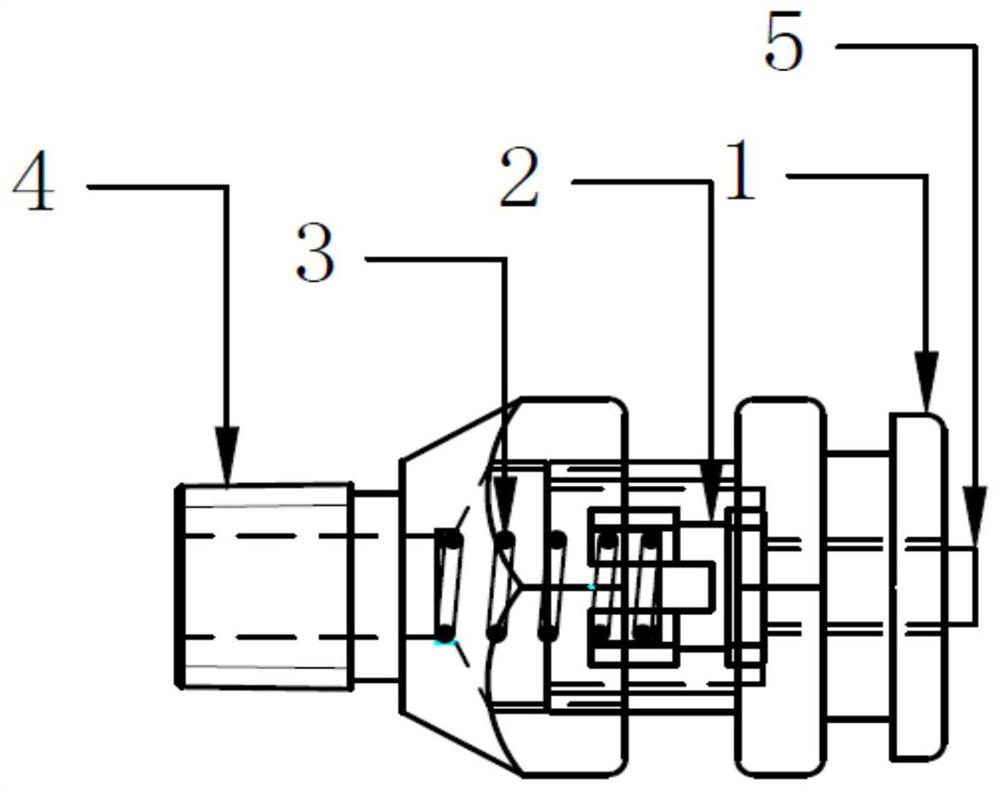

[0032] Such as figure 1 and figure 2 As shown, the generator cover injection check valve includes a connector I1, a baffle plate 2, a spring 3, a connector II4, and a dustproof bolt 5.

[0033] The basic implementation is:

[0034] Including connector I1, connector II4, baffle 2 and spring 3;

[0035] The glue injection channel is processed in the connector I1, one end of the connector I1 is connected to the glue gun, and the other end is installed inside the connector II4;

[0036] The baffle plate 2 is installed inside the other end of the connector I1; the glue injection channel is processed in the connector II4, which is connected with the engine end cover;

[0037] A spring 3 is installed between the baffle 2 and the connection head II4, the spring 3 is located in the direction of the glue injection channel, and exerts pressure in the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com