Locking mechanism and locking structure of brake pedal arm and vacuum booster push rod

A locking mechanism and push rod technology, applied in brakes, brake components, transportation and packaging, etc., can solve the problems of difficult processing, small radial projection area, inconvenient positioning, etc., to reduce the risk of worker injury and reduce the number of , the effect of preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

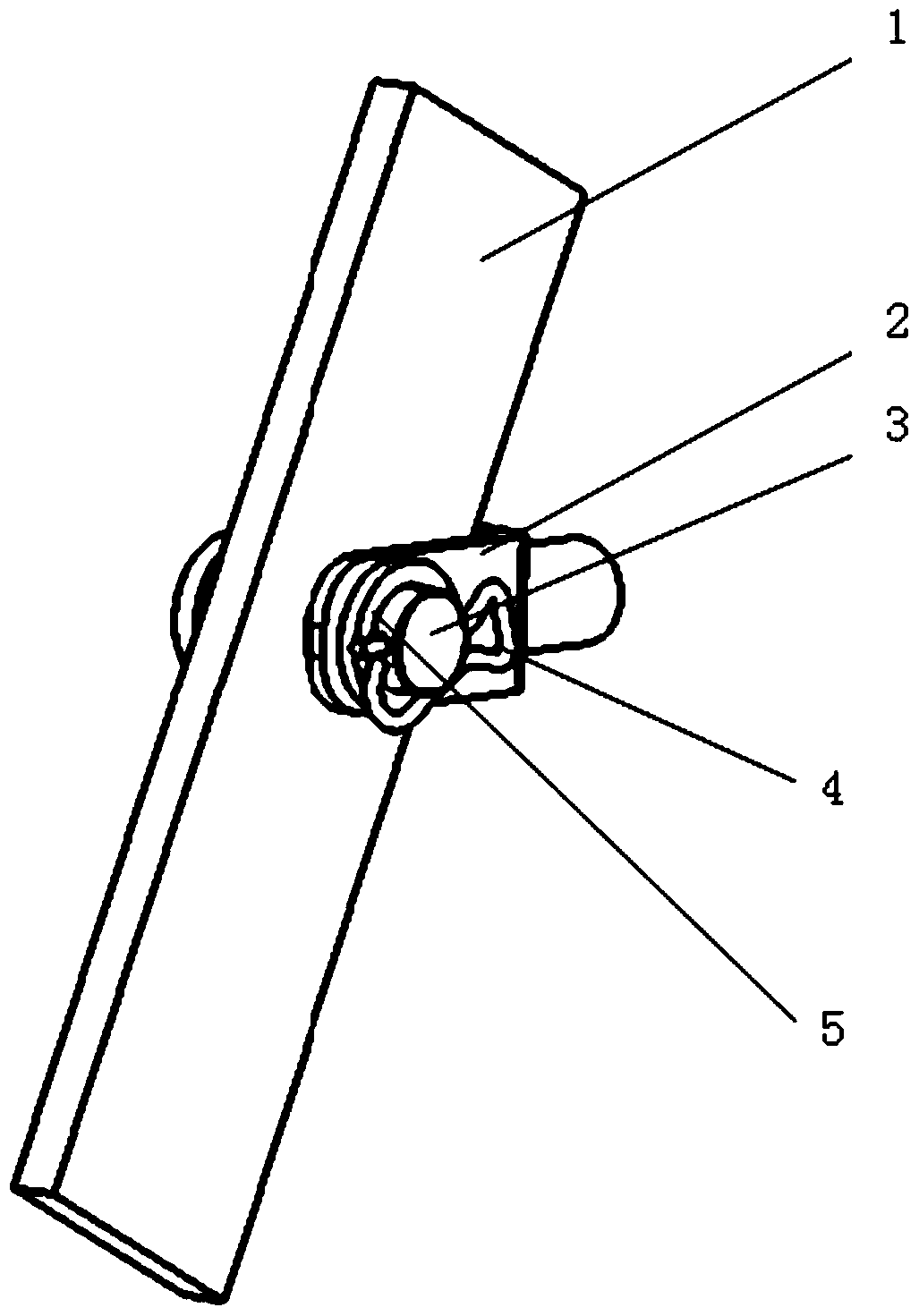

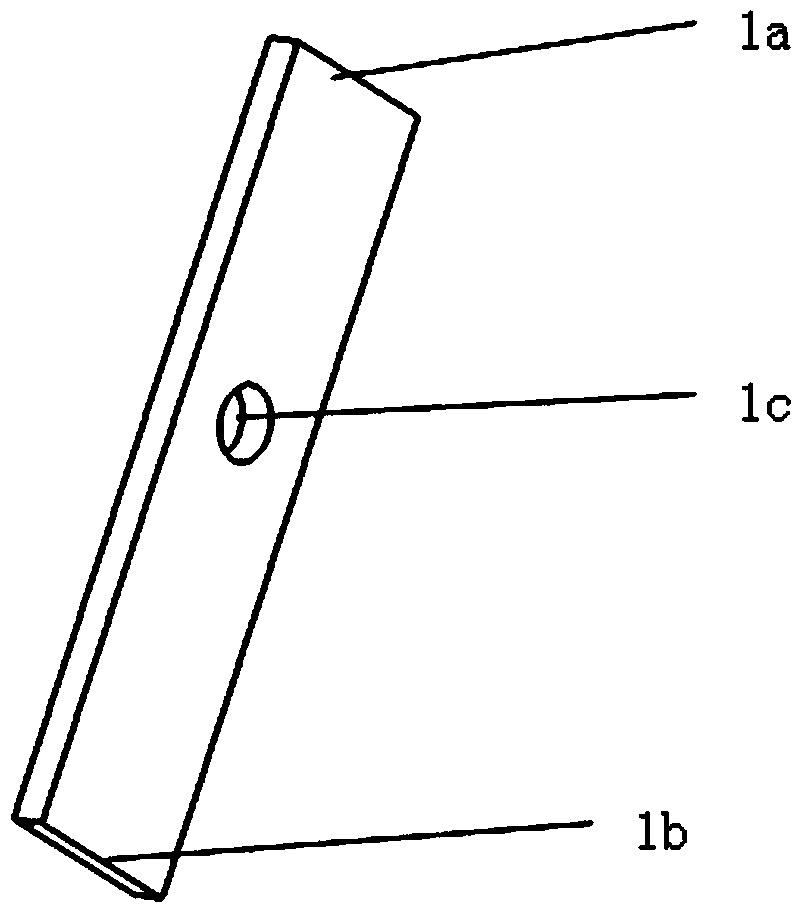

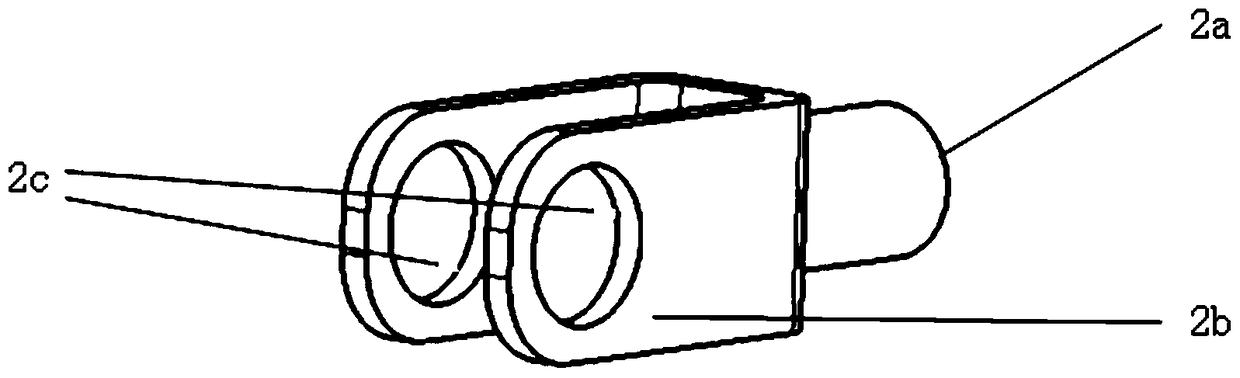

[0038] refer to Figure 7 , The locking structure of the brake pedal arm and the vacuum booster push rod in this embodiment includes the brake pedal arm 1, the vacuum booster push rod assembly 2 and the locking mechanism. Wherein, the structures of the brake pedal arm 1 and the vacuum booster push rod assembly 2 are the same as those described in the background art, and will not be described in detail here. The improvement lies in the locking mechanism, including the locking pin 6 and the locking piece 7 .

[0039] refer to Figure 8 The locking pin 6 used in the locking mechanism of this embodiment has a cap portion 6b and a rod portion 6c, the rod portion 6c is provided with a circumferential ring groove 6a, and the rod portion 6c extends from the ring groove 6a in a direction away from the cap portion 6b. Section 6d. The axial length of end 6d is marked L and the diameter d1. The diameter of the rod portion 6c except the ring groove 6a and the end portion 6d can be the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com