Plasma cleaning device

A technology of plasma cleaning and plasma cavity, which is applied in the field of ion surface treatment devices and its control, can solve the problems of affecting the electrical properties of the surface medium, the easy loss of the surface medium, the density of the ion beam, and the high bombardment intensity, etc., so as to avoid the surface properties of the medium Effect of drift or thickness loss, precise control of ion bombardment intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0042] This embodiment adopts an integrated plasma chamber. In the plasma chamber, the deflecting electric field overlaps with the accelerating electric field. When the ions pass through the electric field filter, they are still accelerated by the accelerating electric field.

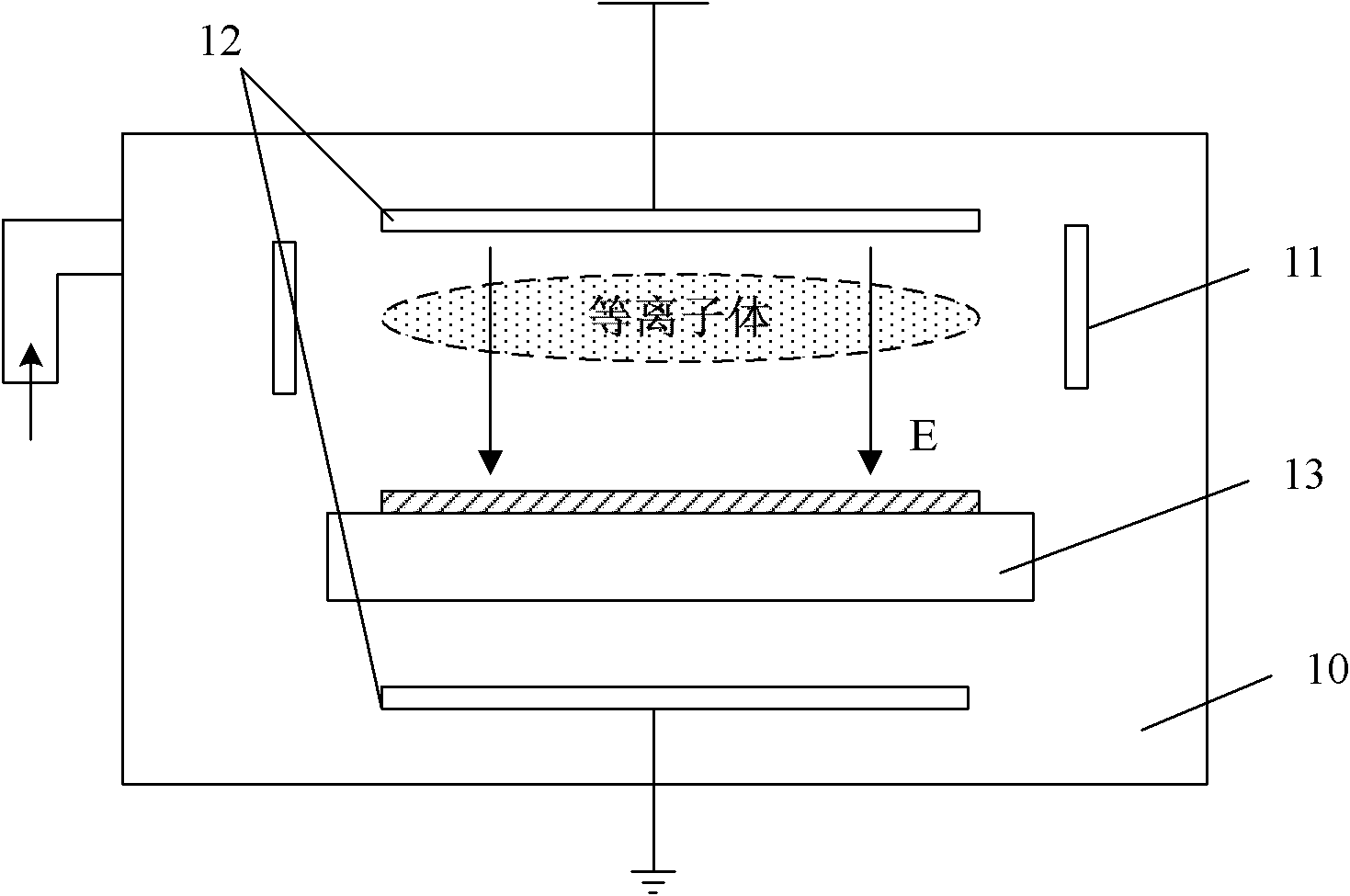

[0043] like image 3 As shown, the plasma cleaning device described in this embodiment includes:

[0044] The plasma chamber 200 is arranged on the base 201 at the bottom of the plasma chamber 200;

[0045] A vent pipe 202 connected to the plasma chamber 200 is used to introduce a cleaning gas as a plasma source into the plasma chamber 200;

[0046] Plasma generator 203, the plasma generator 203 can be inductively coupled plasma (ICP), and the cleaning gas in the plasma chamber 200 is ionized by passing high-frequency radio frequency signals to the electrodes arranged around the chamber , forming plasma;

[0047] Ion accelerator 204, described ion accelerator 204 comprises the upper electrode plate 2...

no. 2 example

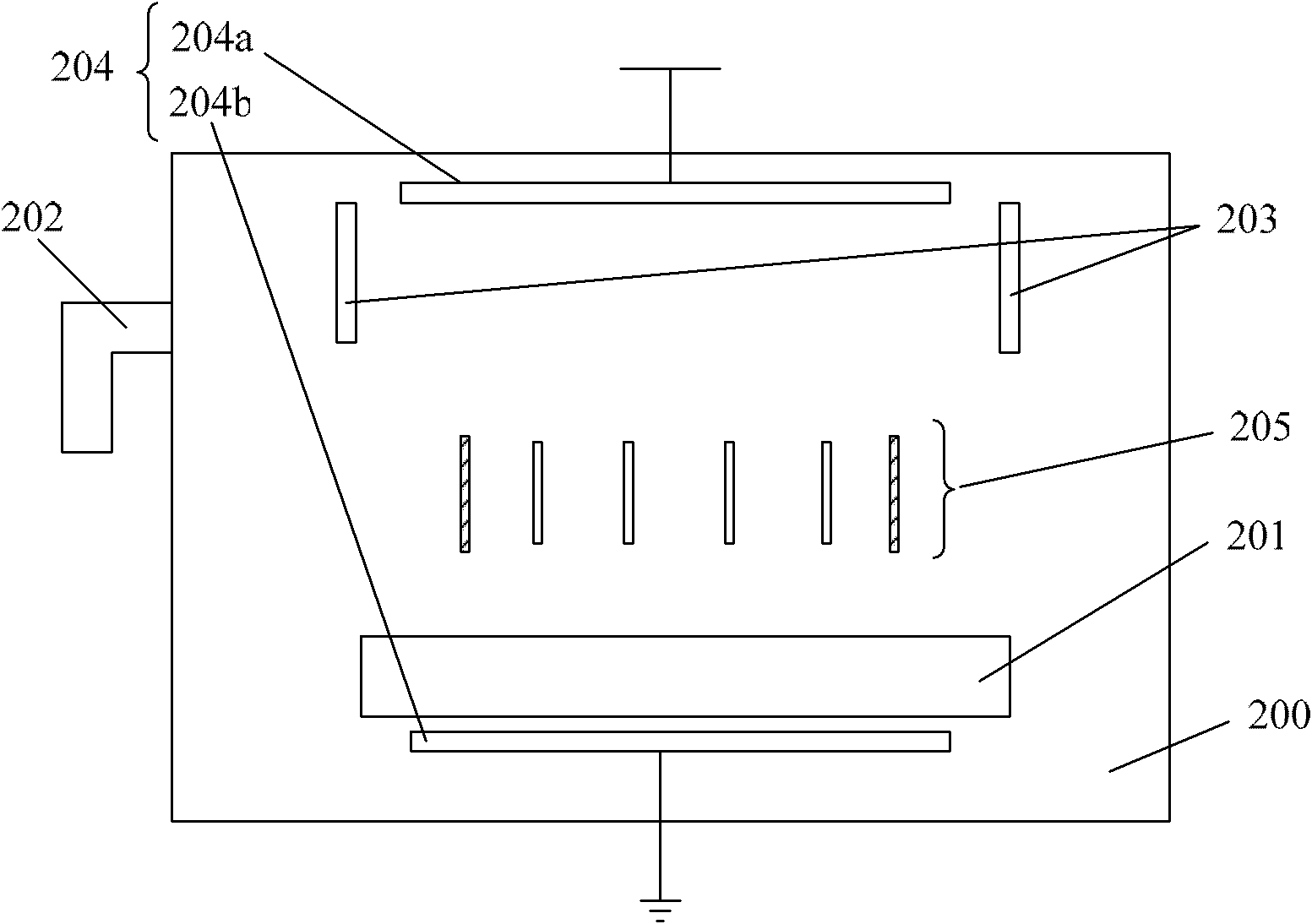

[0061] In the foregoing embodiments, the structure of the device is relatively simple, and the accelerating electric field and the deflecting electric field overlap. Although the uniform electric field is taken as an ideal model, the electric field in the integrated plasma chamber is actually more complicated. The difference in electric field and plasma density in different regions will easily affect the uniformity of ions bombarded on the surface of the workpiece. This embodiment also provides a plasma cleaning device using a biased plasma source, so that the deflection electric field and the acceleration electric field are isolated without affecting each other.

[0062] like Image 6 As shown, the difference between the plasma cleaning device described in this embodiment and the first embodiment is:

[0063] The plasma generator 203 and the ion accelerator 204 are all biased at the top of the plasma chamber, wherein the ion accelerator 204 can be an electromagnetic coil acc...

no. 3 example

[0083] This embodiment adopts an integrated plasma chamber. In the plasma cavity, the deflection magnetic field overlaps with the accelerating electric field. When the ions pass through the magnetic field filter, they are still accelerated by the accelerating electric field.

[0084] like Figure 10 As shown, the plasma cleaning device described in this embodiment includes:

[0085] The plasma chamber 400 is set on the base 401 at the bottom of the plasma chamber 400;

[0086] A vent pipe 402 connected to the plasma chamber 400 is used to introduce cleaning gas as a plasma source into the plasma chamber 400;

[0087] Plasma generator 403, the plasma generator 403 can be an inductively coupled plasma generator (ICP), by passing high-frequency radio frequency signals to the electrodes arranged around the chamber, the cleaning gas in the plasma chamber 400 Ionize to form plasma;

[0088] Ion accelerator 404, described ion accelerator 404 comprises the upper electrode plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com