Temperature-responsive high temperature retarder suitable for oil-gas well cementation, preparation method thereof and well cementing slurry

A technology of cementing slurry and temperature response, which is applied in the preparation of high-temperature retarder and in the field of cementing slurry to achieve strong high-temperature retarding effect, weaken the side effects of excessive dispersion, and prolong the effect of thickening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

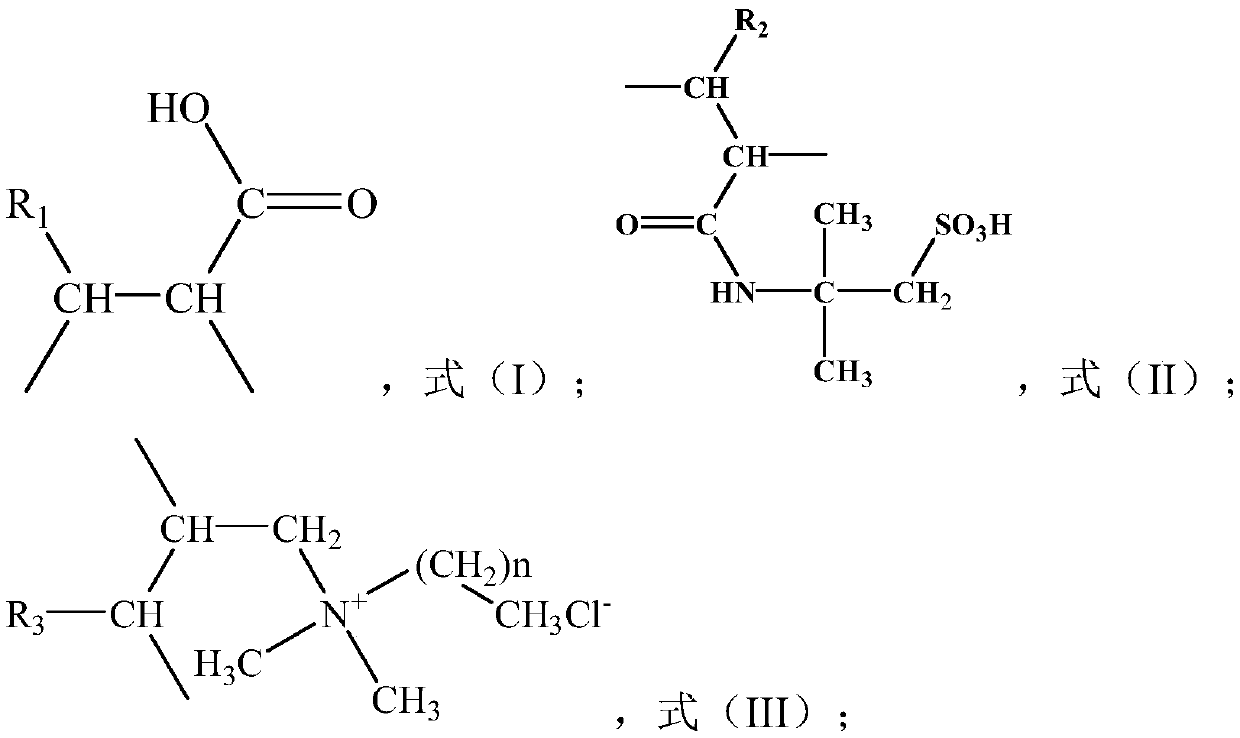

[0046] In the present invention, by increasing the length of the alkyl chain in the monomer, a rigid hydrophobic monomer is developed. The rigid hydrophobic monomer is a rigid hydrophobic long-chain alkyl monomer that can give the The characteristics of the temperature response of synthetic polymers, therefore, the present invention uses chloropropylene and N,N-dimethyl long-chain alkyl tertiary amine (long-chain alkyl number is an even number of 14-24) to synthesize a rigid hydrophobic long-chain alkane A quaternary ammonium salt-containing monomer is used as a rigid hydrophobic monomer. The specific synthesis method includes the following steps:

[0047] (1) Add fatty alcohol and appropriate amount of catalyst into the reactor, heat the reactor, and pass monomethylamine into the reactor at a flow rate of 35kg / h-50kg / h at a temperature of 130℃ for 75-85min, and the final reactor Keep the reaction temperature at 180-200°C and the reaction time for 5-7h to synthesize N,N-dimethyl ...

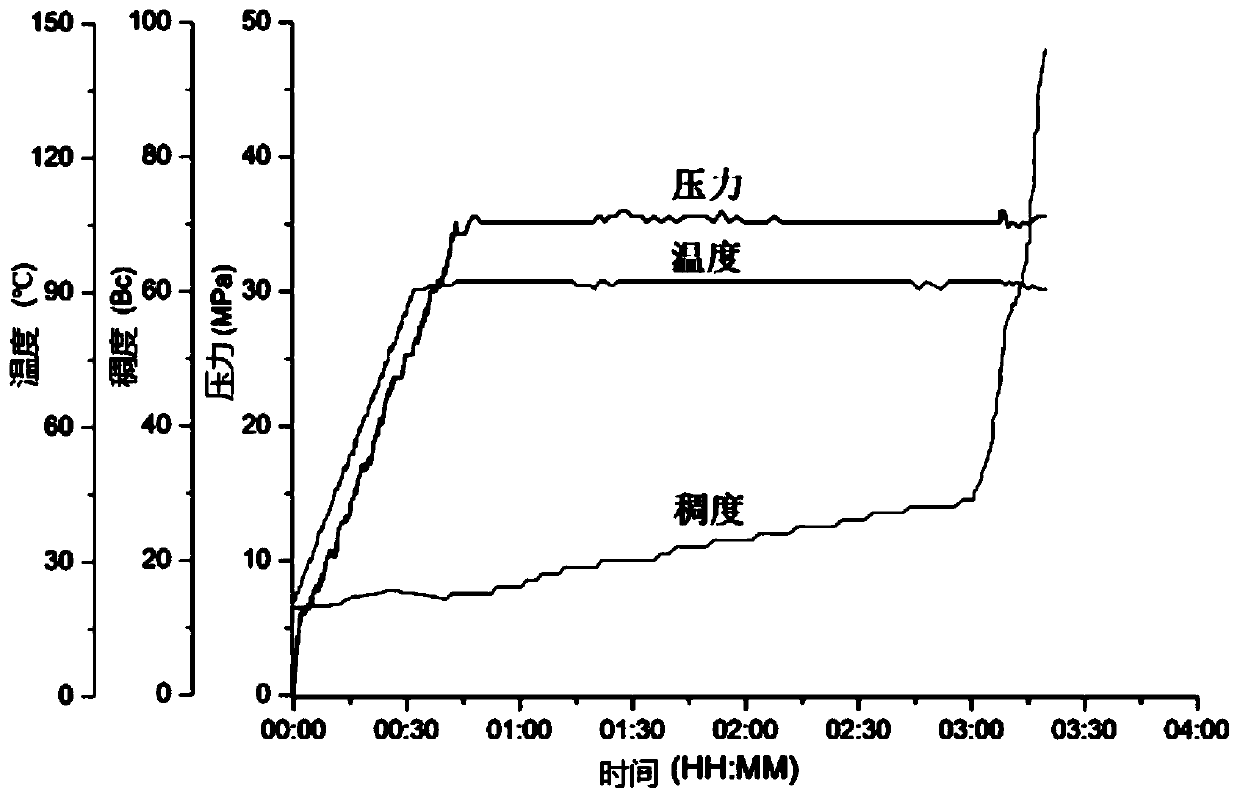

Embodiment 1

[0083] This example is to illustrate the temperature-responsive high-temperature retarder prepared by the method of the present invention.

[0084] The preparation steps are as follows:

[0085] (1) Weigh 51.75 parts of 2-acrylamide-2-methylpropanesulfonic acid (monomer B), 21.6 parts of acrylic acid (monomer A), and 6 parts of hydrophobic monomer (monomer C) respectively, and use deionization Dissolve in water, the total mass concentration of the monomers in the solution is 25%, and the pH value is adjusted to 6 by a sodium hydroxide solution with a concentration of 5mol / L;

[0086] Wherein, the rigid hydrophobic monomer has a structure represented by formula (VI), and R 6 Is H, n is 21;

[0087]

[0088] (2) Adjust the temperature of the water bath to 55°C and install the reaction device. The mixed solution of 2-acrylamide-2-methylpropanesulfonic acid, acrylic acid, and hydrophobic monomer was transferred into a three-necked flask, stirred with a magnetic stirrer, the speed was mai...

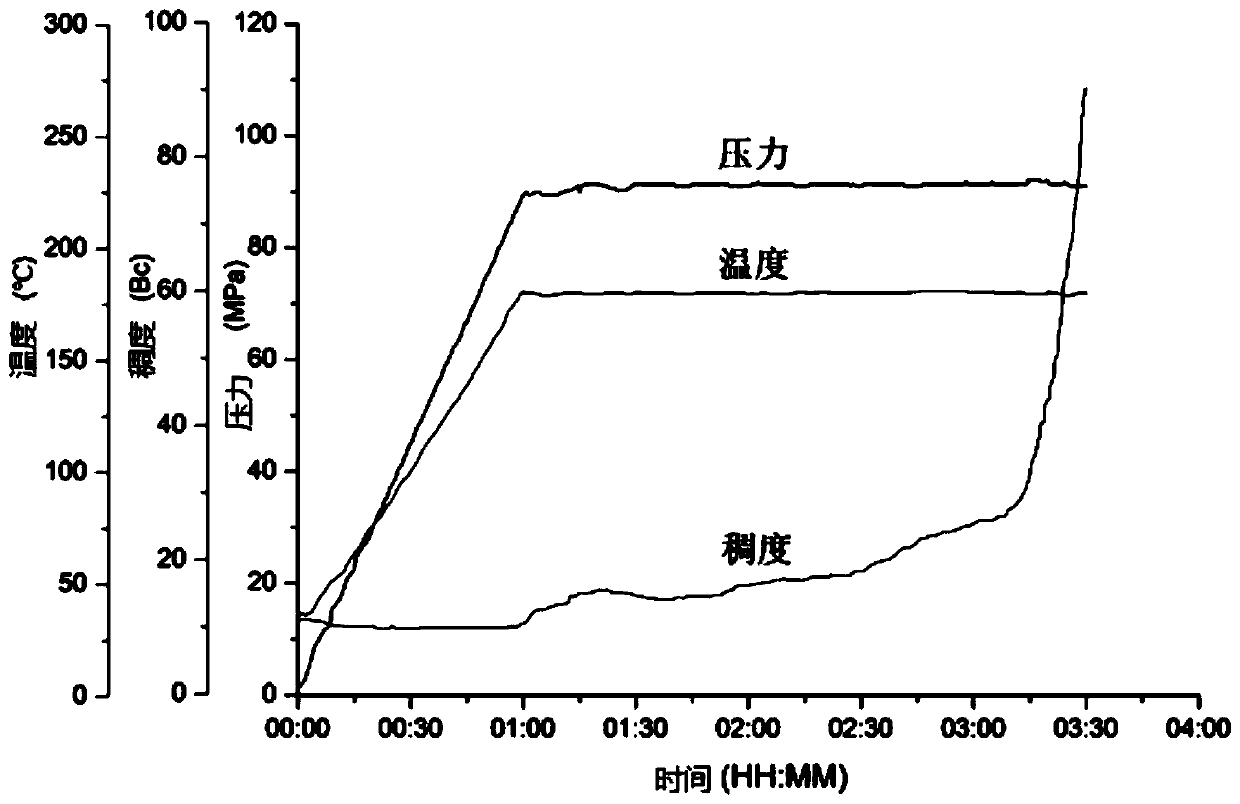

Embodiment 2

[0095] This example is to illustrate the temperature-responsive high-temperature retarder prepared by the method of the present invention.

[0096] The high temperature retarder was prepared according to the same method as in Example 1, except that: 2-acrylamide-2-methylpropanesulfonic acid (monomer B) and acrylic acid (monomer A) were weighed according to the weight ratio. And hydrophobic monomer (monomer C).

[0097] Results The prepared high temperature retarder was marked as S2.

[0098] Among them, the structure of the high temperature retarder S2 is:

[0099] [CH 2 CM 1 H] x -[CM 2 HCH 2 ] y -[CH 2 CM 3 HCl - ] z ; Among them, M 1 For -COOH, M 2 For -CONHC(CH 3 ) 2 CH 2 SO 3 H, M 3 As-[NCH 2 (CH 3 ) 2 (CH 2 ) n CH 3 ] + ;

[0100] Wherein, x=39.45%, y=59.17%, z=1.38%; and

[0101] The weight average molecular weight of the high temperature retarder S2 is 150,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com