Retarding thermosetting resin gelling composition and preparation method thereof

A thermosetting resin and composition technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems that the thickening time is difficult to control stably and cannot be satisfied, and achieve the effect of prolonging the thickening time and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

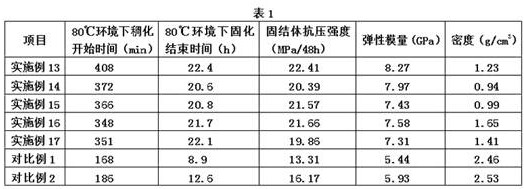

Examples

Embodiment 1

[0020] Embodiment 1: The slow-setting thermosetting resin gel composition, the raw materials include 80 to 120 parts of metal oxide, 30 to 60 parts of phosphate, 10 to 50 parts of thermosetting resin, resin 5 to 15 parts of curing agent, 1 to 6 parts of fluid loss reducing agent, 10 to 20 parts of composite regulator, and 30 to 120 parts of water. The composite regulator is made of stearyl acrylate-styrene-maleic anhydride copolymer Compound, sodium alkylbenzene sulfonate and porous glass microspheres are compounded according to the weight ratio of 3:2 to 5:1, and obtained according to the following steps: the first step, weigh the required amount of sodium alkylbenzene sulfonate and Octadecyl acrylate-styrene-maleic anhydride copolymer, after mixing and grinding to a particle size of 100nm to 200nm, the first mixture is obtained; in the second step, the required amount of porous glass beads is added to the first mixture, Control the stirring speed at 100rpm to 200rpm and stir...

Embodiment 2

[0021] Embodiment 2: The slow-setting thermosetting resin gelling composition, the raw materials include 80 or 120 parts of metal oxides, 30 or 60 parts of phosphates, 10 or 50 parts of thermosetting resins, resin 5 or 15 parts of curing agent, 1 or 6 parts of fluid loss reducer, 10 or 20 parts of composite regulator and 30 or 120 parts of water, composite regulator is copolymerized by stearyl acrylate-styrene-maleic anhydride Compound, sodium alkylbenzene sulfonate and porous glass microspheres are compounded according to the weight ratio of 3:2 or 5:1, and obtained according to the following steps: the first step, weigh the required amount of sodium alkylbenzene sulfonate and Octadecyl acrylate-styrene-maleic anhydride copolymer, after mixing and grinding to a particle size of 100nm or 200nm, the first mixture is obtained; in the second step, the required amount of porous glass beads is added to the first mixture, After controlling the stirring speed at 100rpm or 200rpm and ...

Embodiment 3

[0024] Embodiment 3: As an optimization of the above embodiments, the metal oxide is at least one of dead-burned magnesia, aluminum oxide, iron oxide, dicalcium oxide and metakaolin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com