Foam concrete prepared from undisturbed desulfurization gypsum and preparation method thereof

A technology of foam concrete and desulfurized gypsum, which is applied in the field of building materials, can solve the problems of resource waste and inability to be used to prepare foam concrete, and achieve the effects of preventing mold collapse, saving natural resources, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

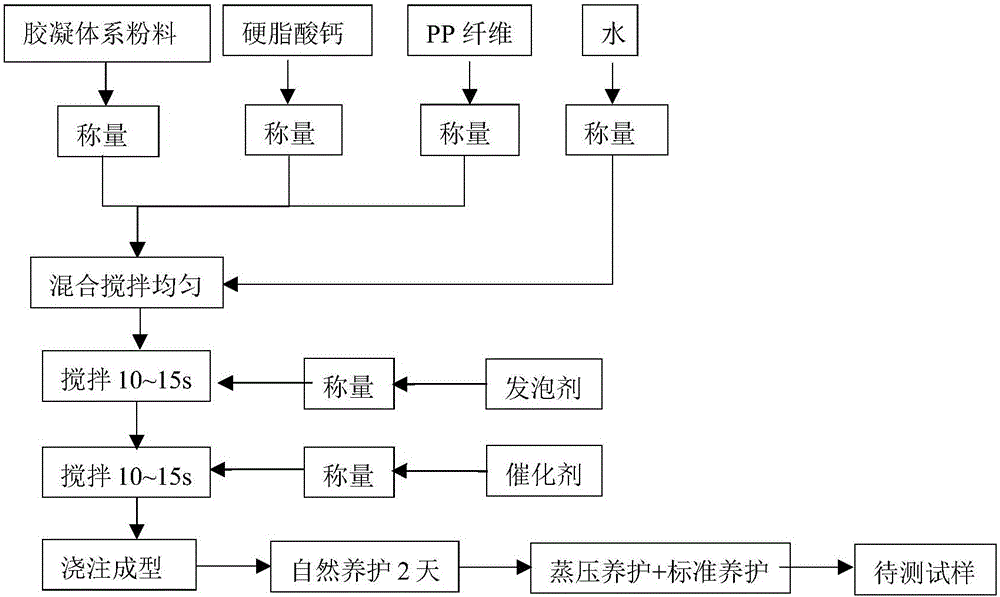

Method used

Image

Examples

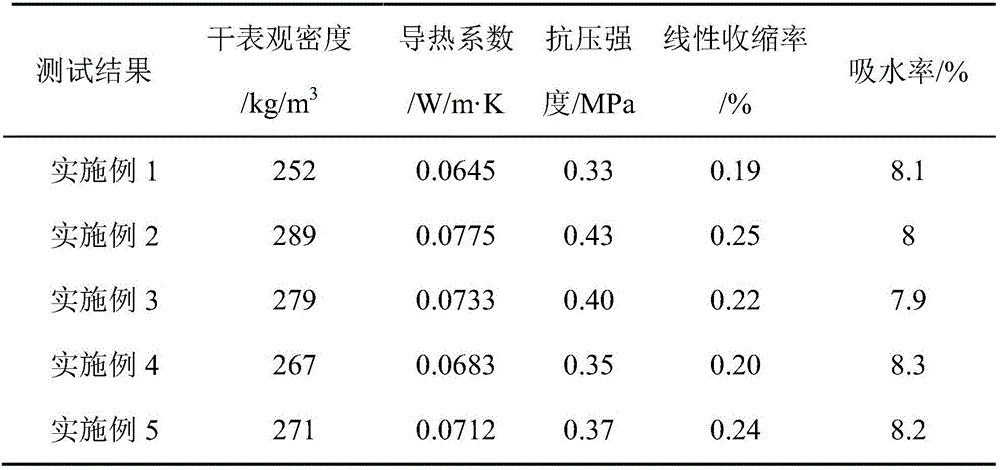

Embodiment 1

[0033] An original desulfurization gypsum foam concrete, wherein the original desulfurization gypsum includes wet desulfurization gypsum and dry desulfurization gypsum, and the raw material of the foam concrete is composed of the following components in parts by weight: wet desulfurization gypsum with an attached water content of 7% 30 parts, the density is 2.35g / cm 3 27 parts of dry desulfurization gypsum, specific surface area 350m 2 28 parts of slag powder per kg, 6 parts of cement, 9 parts of ash calcium powder with a fineness of 300 mesh, 0.63 parts of water reducer, 1.9 parts of alkaline activator with a modulus of 1.4, 2.3 parts of foaming agent, and foam stabilizer 2.8 parts, 0.03 parts of catalyst, 0.17 parts of polypropylene fiber with a length of 6mm, and 42 parts of water.

[0034] Wherein, cement adopts commercially available 52.5 cement; Gray calcium powder adopts commercially available gray calcium powder; Foaming agent is hydrogen peroxide H 2 o 2 , its acti...

Embodiment 2

[0036] An original desulfurization gypsum foam concrete, wherein the original desulfurization gypsum includes wet desulfurization gypsum and dry desulfurization gypsum, and the raw material of the foam concrete is composed of the following components in parts by weight: wet desulfurization gypsum with an attached water content of 15% 50 parts, the density is 2.65g / cm 3 13 parts of dry desulfurization gypsum, specific surface area 450m 2 19 parts of slag powder per kg, 11 parts of cement, 7 parts of ash calcium powder with a fineness of 450 mesh, 0.70 parts of water reducer, 1.0 part of alkaline activator with a modulus of 2.0, 2.7 parts of foaming agent, and foam stabilizer 3.4 parts, 0.05 parts of catalyst, 0.13 parts of polypropylene fiber with a length of 12 mm, and 35 parts of water.

[0037] Wherein, cement adopts commercially available 52.5 cement; Gray calcium powder adopts commercially available gray calcium powder; Foaming agent is hydrogen peroxide H 2 o 2 , its a...

Embodiment 3

[0039] An original desulfurized gypsum foam concrete, wherein the original desulfurized gypsum includes wet-process desulfurized gypsum and dry-process desulfurized gypsum, and the raw material of the foam concrete is composed of the following components in parts by weight: wet-process desulfurized gypsum with an attached water content of 10% 32 parts, the density is 2.50g / cm 3 32 parts of dry desulfurization gypsum, specific surface area 400m 2 22 parts per kg of slag powder, 8 parts of cement, 6 parts of ash calcium powder with a fineness of 400 mesh, 0.66 parts of water reducer, 1.3 parts of alkaline activator with a modulus of 1.6, 2.5 parts of foaming agent, and foam stabilizer 3.2 parts, 0.04 parts of catalyst, 0.15 parts of polypropylene fiber with a length of 9 mm, and 38 parts of water.

[0040] Wherein, cement adopts commercially available 52.5 cement; Gray calcium powder adopts commercially available gray calcium powder; Foaming agent is hydrogen peroxide H 2 o 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com