Early-strength setting-retarding high pier stud machine-made sand concrete and preparation method thereof

A machine-made sand and retarding technology, applied in the field of concrete, can solve the problems that concrete retardation and early strength cannot be guaranteed at the same time, high stone powder content, high mud content, etc., to achieve long setting time, prolong setting time, and ensure The effect of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

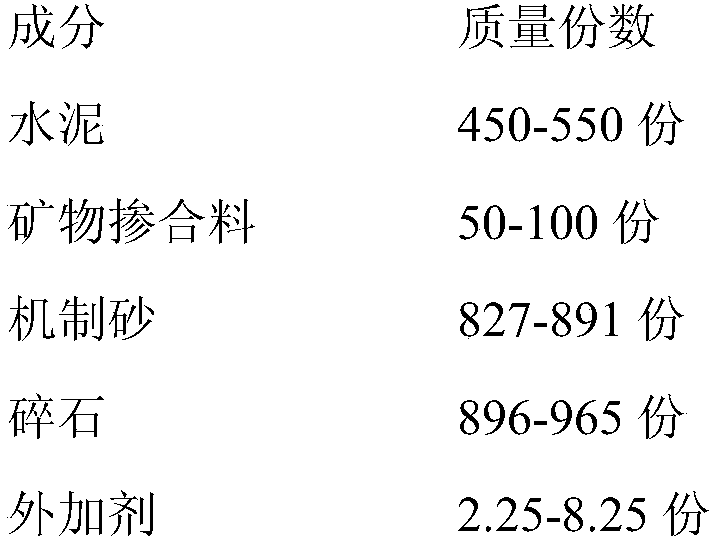

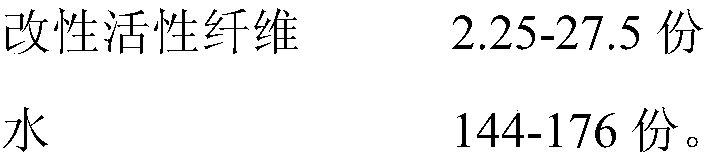

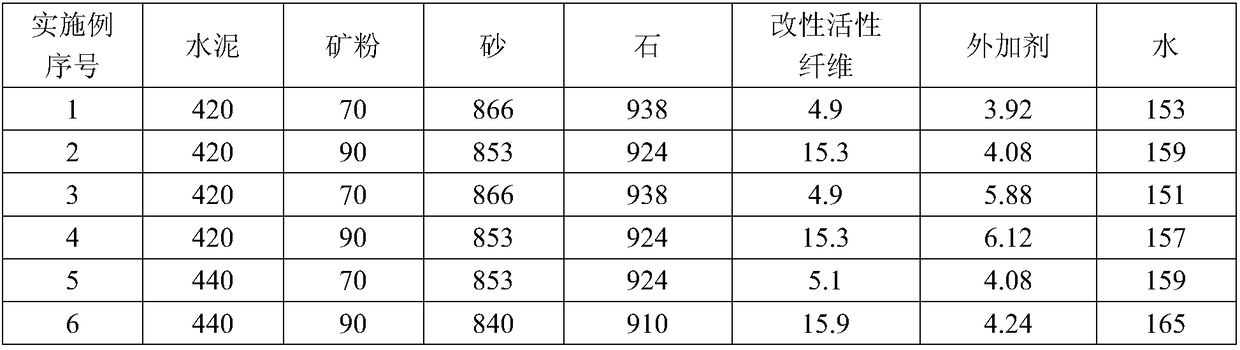

[0023] An early-strength and retarded-setting type high pier-column machine-made sand concrete, which is composed of cement, mineral admixture, sand, stone, composite admixture, modified active fiber and water and other raw materials. The mass parts of each component are shown in the table 1.

[0024] The mass parts of each component of table 1

[0025]

[0026]

[0027] The cement is P.II 42.5R cement, SO 3 = 2.84%, MgO = 2.06%, cement fineness = 3.42%, loss on ignition ≤ 0.28%, initial setting time = 80min, final setting time = 140min, 3d compressive strength = 24.1MPa, 28d compressive strength = 45.8MPa .

[0028] The mineral admixture is mineral powder, SiO 2 、Al 2 o 3 And the total content of CaO is 87.1%, and the specific surface area is 440m 2 / kg.

[0029] The machine-made sand is crushed from natural rock ore, with stone powder content ≤ 10%, MB value = 0.8%, and fineness modulus: 2.9.

[0030] The crushed stones are natural rock ore crushed stones, the ...

Embodiment 9-11

[0044] An early-strength and slow-setting type high pier-column machine-made sand concrete, which is composed of cement, mineral admixture, sand, stone, composite admixture, modified active fiber and water and other raw materials, cement, mineral admixture, sand, Stone and water carry out batching by table 1 embodiment 2. Embodiment 9 is compared with Example 2, no modified active fiber is added, and the composite admixture is the same as Example 2; Embodiment 10 is compared with Example 2, and the composite admixture that is added does not contain Meishan New Materials. Adhesive and mud-repelling agent, solid content and water reducing rate are constant, modified active fiber is the same as embodiment 2; Compared with embodiment 2 in embodiment 9, no modified active fiber is added, and the compound admixture added Meishan Xincai viscosity reducer and mud inhibitor are not included in the formula, and the solid content and water reducing rate remain unchanged. The index and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com