Low-temperature cement and preparation method thereof

A cement and low temperature technology, applied in the field of low temperature cement and its preparation, can solve the problems of low strength, complicated construction, unsuitable for large-scale use, etc., to improve the early strength and late strength, ensure early strength and late strength, and shorten cement coagulation. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

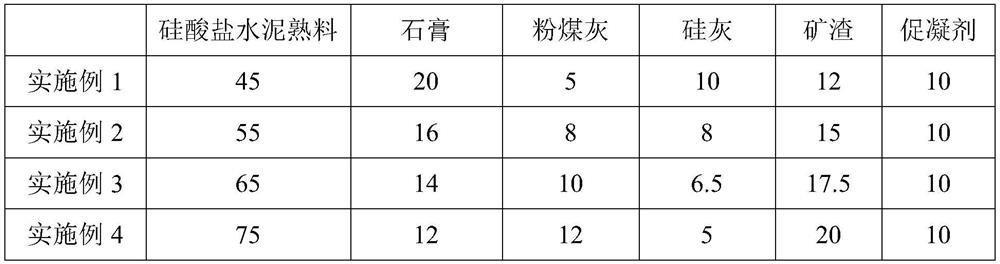

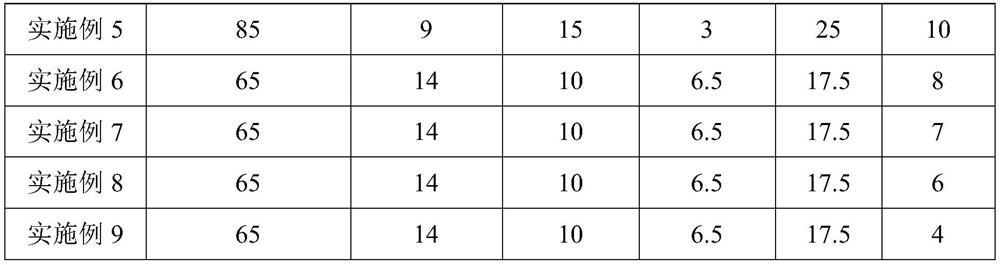

Examples

preparation example Construction

[0039] Examples of Preparation of Raw Materials and / or Intermediates

[0040] raw material

[0041] Portland cement clinker was purchased from Lingshou County Yanhang Mineral Products Processing Plant;

[0042] Gypsum, industrial grade, 99%, purchased from Hebei Shibide Building Materials Co., Ltd.;

[0043] Fly ash, grade 2, was purchased from Lanxiang Mineral Products Processing Plant in Lingshou County;

[0044] Silica fume was purchased from Shijiazhuang Tourmaline Mineral Products Co., Ltd.;

[0045] Slag was purchased from Ma Lin Mineral Products Processing Plant in Lingshou County;

[0046] Aluminum sulfate, as Al 2 (SO 4 ) 3 18H 2 O, analytically pure, purchased from Shandong Landing New Energy Technology Co., Ltd.;

[0047] Aluminum hydroxide, industrial grade, purchased from Jinan Chaoyixing Chemical Co., Ltd.;

[0048] Hydrofluoric acid, the HF content in the solution is 40%;

[0049] Diethanolamine, analytically pure, purchased from Shandong Xima Supply C...

preparation example 1

[0059] Fluoroaluminum complex, its preparation method is:

[0060] Weigh 30kg of hydrofluoric acid solution with a mass percent concentration of 40%, heat the hydrofluoric acid solution to 65°C, add 10kg of aluminum hydroxide into the hydrofluoric acid solution while stirring, and continue stirring after adding all the aluminum hydroxide After 30 min, the residue was filtered off and cooled to room temperature to obtain a fluoroaluminum complex.

preparation example 2

[0062] Coagulant, its preparation method is:

[0063] 1) Heat 38kg of water to 65°C, add 31kg of aluminum sulfate into the water while stirring, and stir until the aluminum sulfate is completely dissolved to prepare an aluminum sulfate solution;

[0064] 2) Add 0.4kg diethanolamine and 0.6kgEDTA to the aluminum sulfate solution while stirring and mix evenly to obtain mixed solution A;

[0065] 3) Add 25kg of the fluoroaluminum complex obtained in Preparation Example 1 into the mixed solution A while stirring, then add 0.3kg of sodium formate, 2kg of potassium sulfate, 0kg of nanometer silicon carbide, and 0kg of nanometer magnesium hydroxide, and mix uniformly. A coagulation accelerator is obtained, wherein the particle diameters of the nano-silicon carbide and the nano-magnesium hydroxide are both 10-30 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com