Additive for activating flyash

An additive, fly ash technology, applied in the field of building materials, can solve the problems of increasing the stability of fresh concrete, water consumption and pumping performance, increasing the alkali content of concrete, reducing the strength of concrete, etc., so as to reduce cracking and leakage. Possibility, bleeding reduction, effect of post-strength assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further illustrate the present invention in conjunction with embodiment:

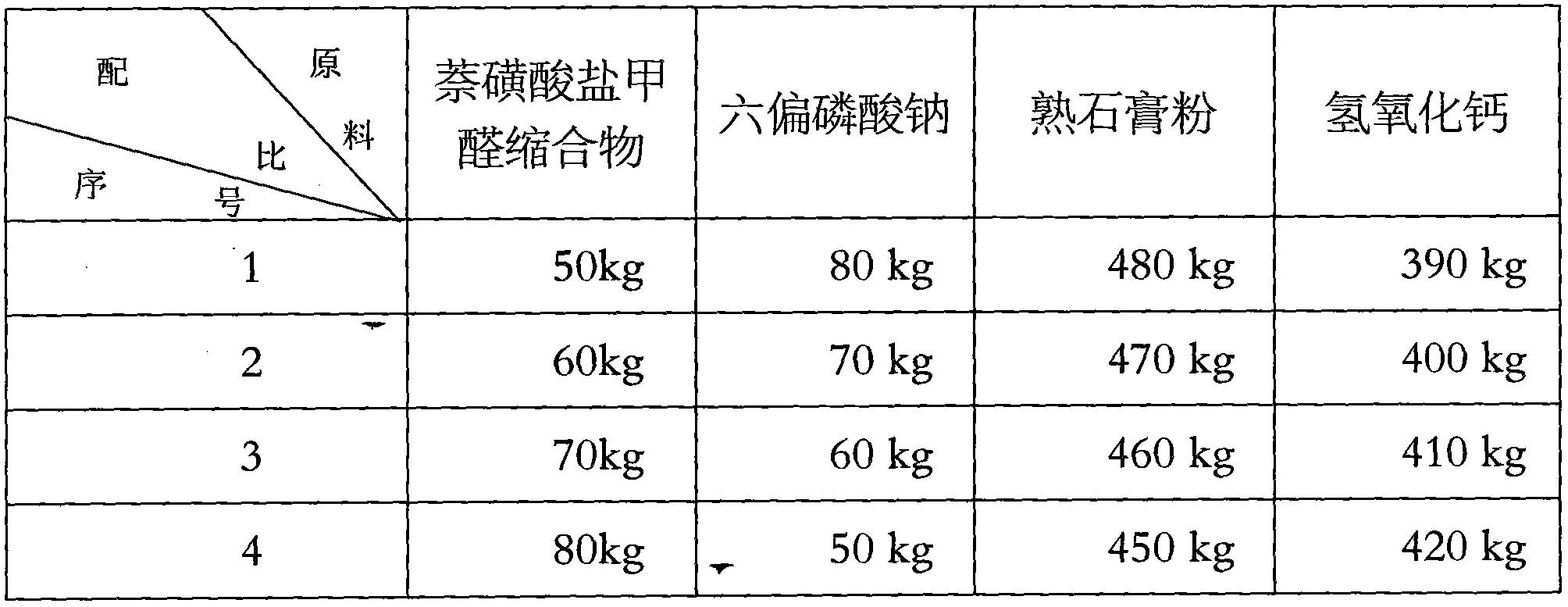

[0018]

[0019] The naphthalenesulfonate formaldehyde condensate used in the present invention is a high-efficiency water reducer powder with a moisture content of ≤5% and a sodium sulfate content of ≤18%; sodium hexametaphosphate is a powder with a content of ≥68%; plaster powder Specific surface area / (m 2 / kg) ≥ 200, 1.18mm sieve residue / % ≤ 0.5; moisture content of calcium hydroxide ≤ 8%, fineness 150 mesh.

[0020] Put the above raw materials into a mixer with a motor of 11KW, a reducer model of BL-23-11, and a speed of 60 rpm according to the corresponding proportion, and fully mix for 30 minutes to obtain a fly ash activation additive. .

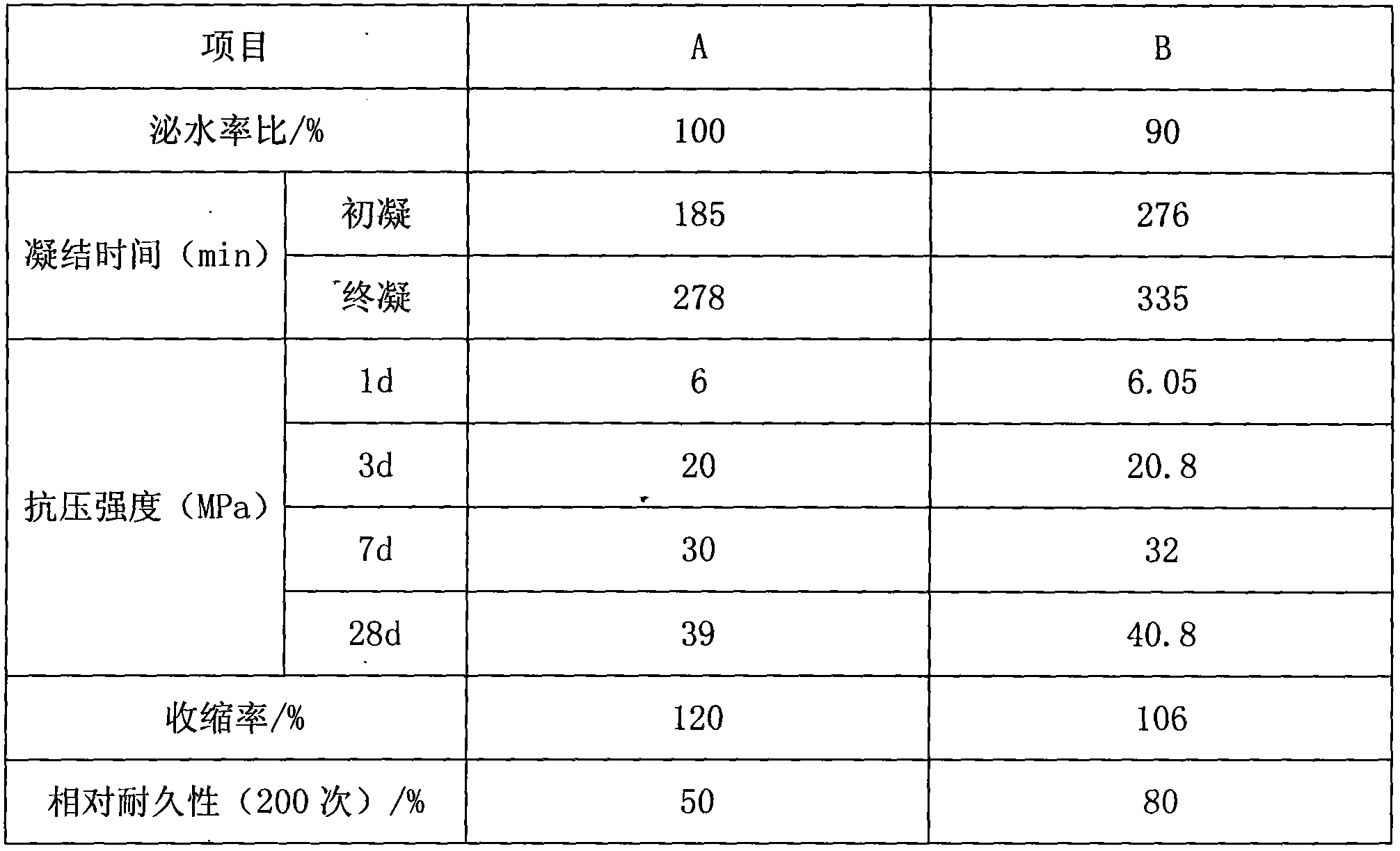

[0021] The mix ratio is designed according to JGJ55 for a set of benchmark concrete A, and the amount of cement in A is 360kg / m 3 , replace cement with 30% fly ash, and mix 2% fly ash activation additive of cementitious material at the same time to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com