Concrete for rapid construction under marine environment and preparation method thereof

A marine environment and concrete technology, applied in the field of concrete materials, can solve problems such as short service life, poor corrosion resistance, and low concrete maturity, and achieve the effects of accelerating hydration reaction, high late strength, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with examples.

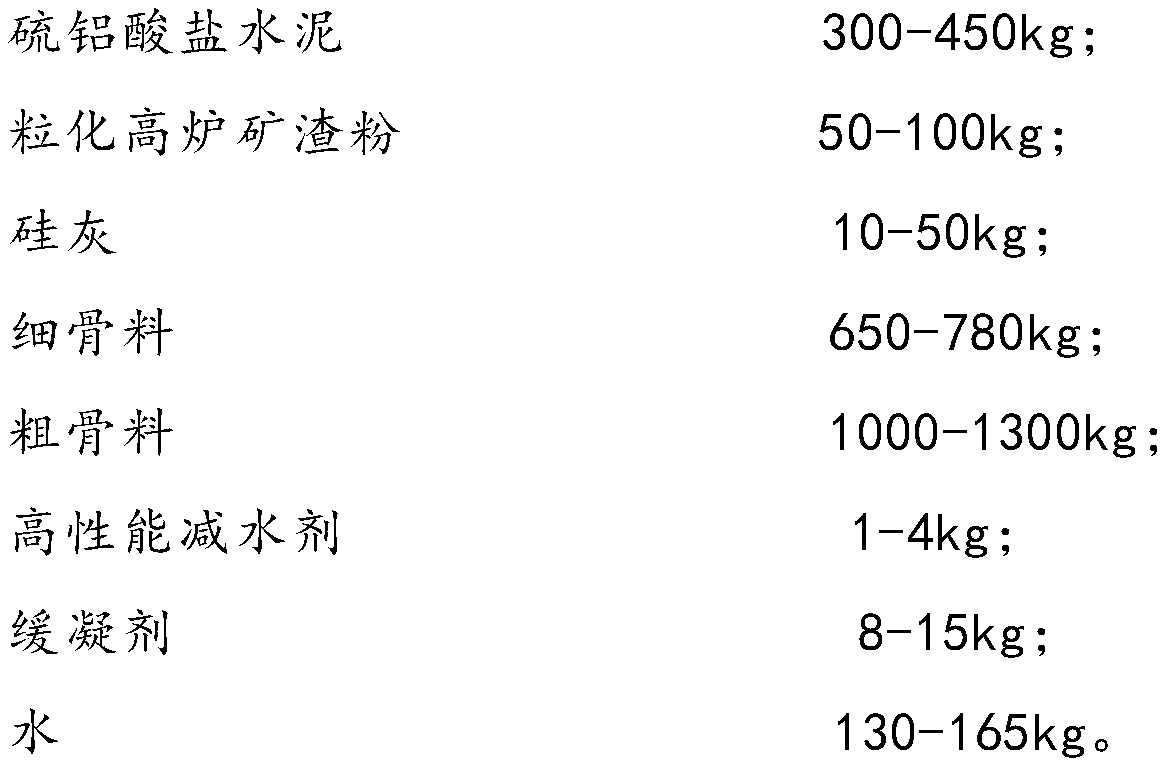

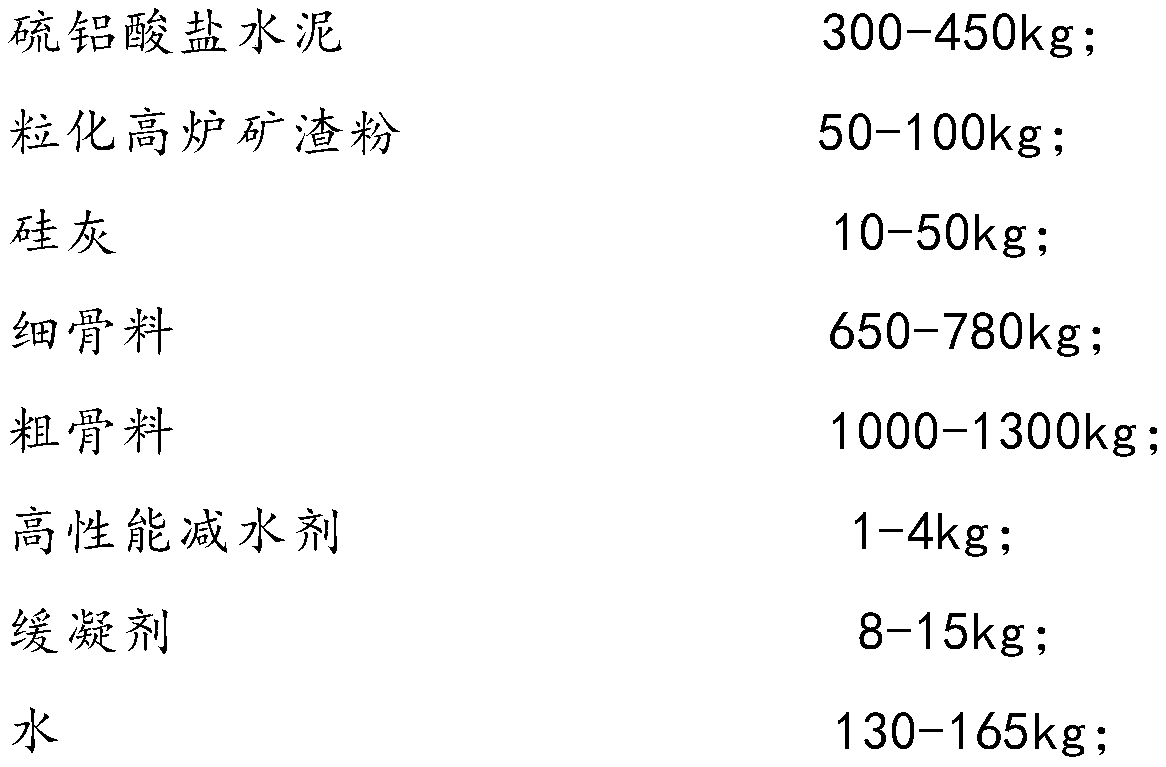

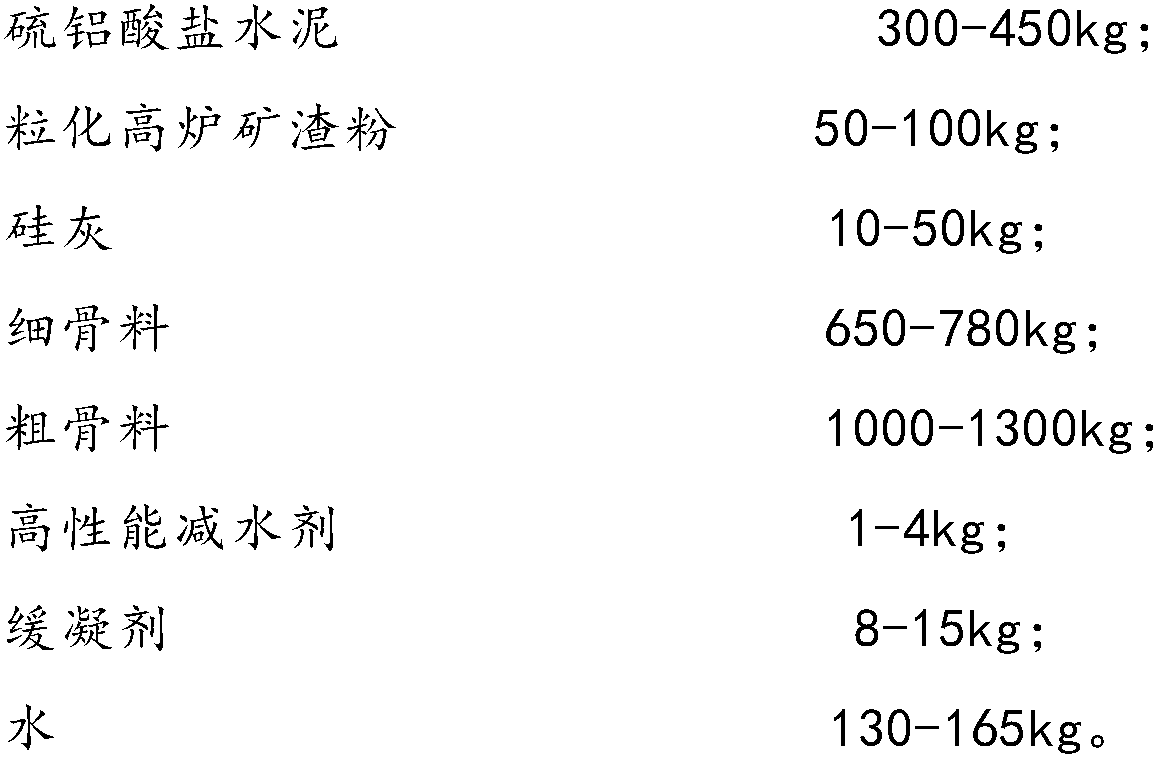

[0023] The raw material component of embodiment 1-5 and comparative example 1 and the consumption of every cubic meter are as shown in table 1:

[0024] The raw material component of table 1 embodiment 1-5 and comparative example 1 and the consumption of every cubic meter

[0025]

[0026]

[0027] Wherein the sulphoaluminate cement in Table 1 adopts the rapid-hardening sulphoaluminate cement whose strength grade is 42.5;

[0028] The grade of granulated blast furnace slag powder is S105; the specific surface area of silica fume is 18500m 2 / kg, and the 28-day activity index of silica fume is 98%; the fine aggregate is medium sand with a fineness modulus of 2.7, the mud content is 0.6%, and the mud content is 0.1%; the coarse aggregate is 5-25mm Continuously graded crushed stone (made from two grades of 5-10mm and 10-25mm, the mass ratio of 5-10mm and 10-25mm is 3:7), the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com