Road as well as water-stable layer and preparation process thereof

A water-stabilizing layer and road technology, applied in the directions of roads, roads, chemical instruments and methods, can solve the problems of poor road structure strength, high cost, easy cracking, etc., and achieve the effect of ensuring strength, good effect, and preventing cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

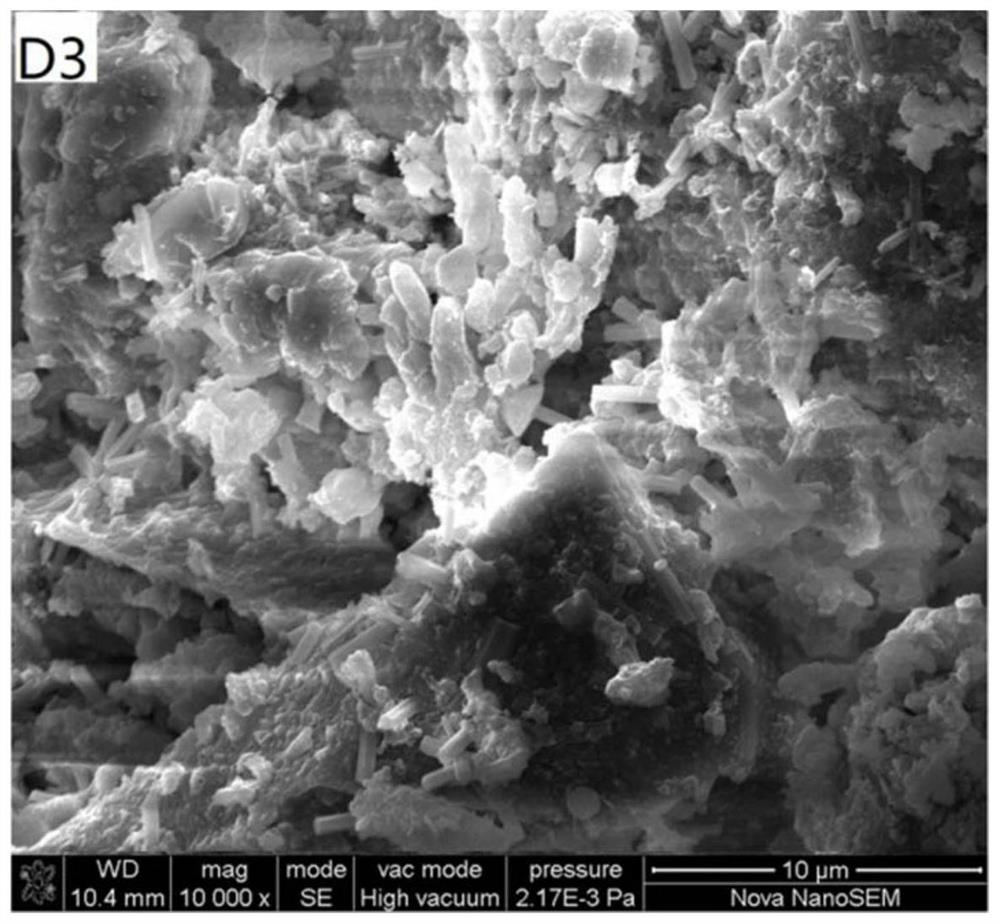

[0030] A water-stabilized layer for roads in this embodiment, the water-stabilized layer is a solidified soil structure layer formed by solidifying a water-stabilized mixture, and the water-stabilized mixture contains modified phosphogypsum, active components, pine Soil and water, wherein the modified phosphogypsum is obtained by calcining phosphogypsum and a modifier at a high temperature of 830°C for 2 hours, and the modifier includes the following components in weight percentage: CaO88%, SiO 2 9%, Al 2 o 3 3%. The mass ratio of the phosphogypsum to the modifier is 1:1, and the active component is water-quenched slag fine powder, and its mass accounts for 50% of the total weight of the modified phosphogypsum and the active component. The particle diameter of the loosened soil is 10-15mm, and the quality of the loosened soil is 10 times of the total weight of the modified phosphogypsum and the active components. The particle size composition of the phosphogypsum is: 2 / g...

Embodiment 2

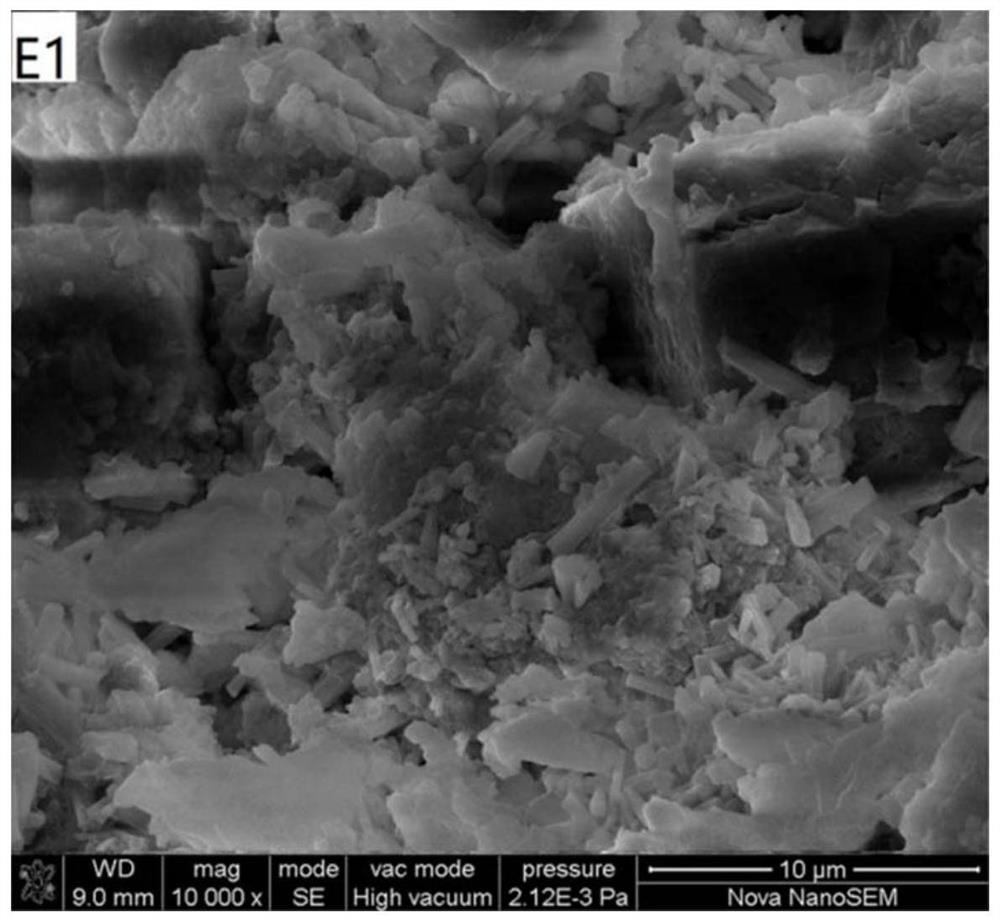

[0063] A water stabilizing layer for roads in this embodiment, the water stabilizing layer is basically the same as in Example 1, the main difference is that in this embodiment the modified calcination temperature is 810°C, the calcination time is 2.5h, and the composition of the modifier is: CaO 94%, SiO 2 4%, Al 2 o 3 2%, the mass ratio of phosphogypsum to modifier is 1:1.3, and the active component is water quenching slag, whose mass accounts for 45% of the total weight of the modified phosphogypsum and the active component. The particle diameter of the loosened soil is 10-15mm, and the quality of the loosened soil is 8 times of the total weight of the modified phosphogypsum and the active components. The specific surface area of the phosphogypsum is 3400cm 2 / g, the specific surface area of the modifier is 3300cm 2 / g, the specific surface area of water-quenched slag is 3000cm 2 / g.

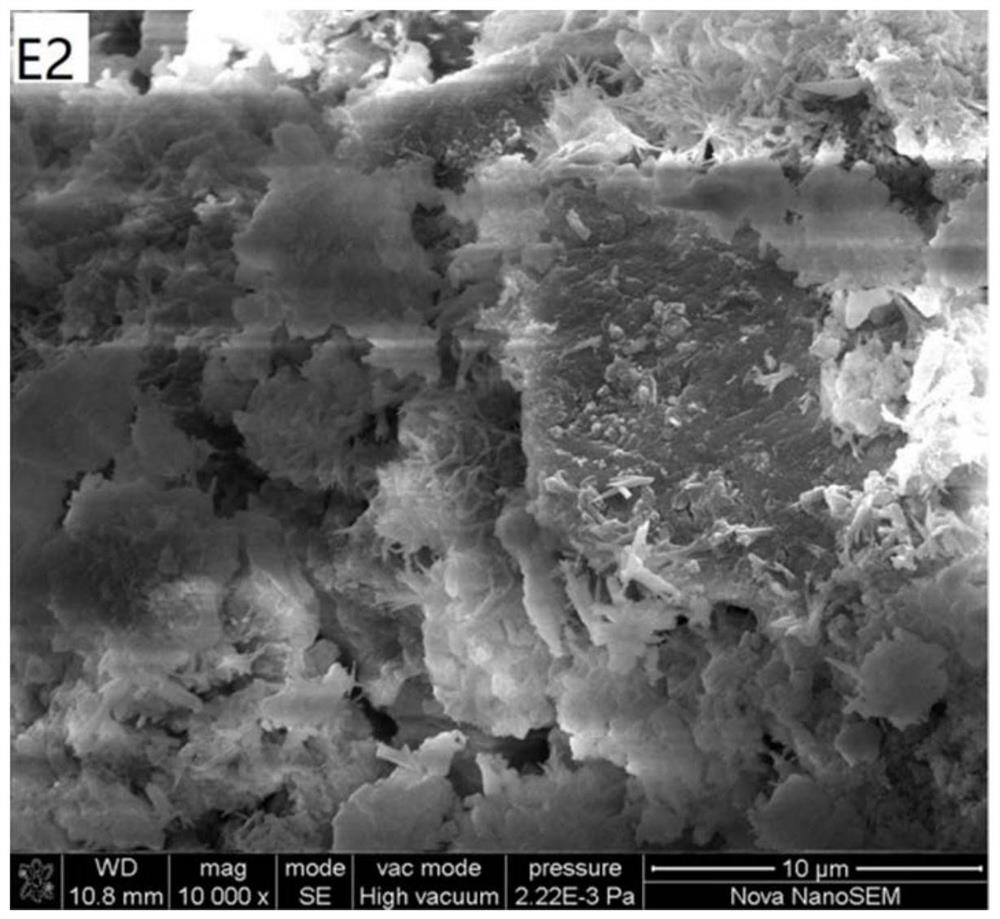

[0064] The preparation method of the road water stabilizing layer of the pre...

Embodiment 3

[0066] A water stabilizing layer for roads in this embodiment, the water stabilizing layer is basically the same as in Example 1, the main difference is that in this embodiment the modified calcination temperature is 880°C, the calcination time is 1h, and the composition of the modifier is: CaO 90%, SiO 2 8.5%, Al 2 o 3 1.5%, the mass ratio of phosphogypsum and modifier is 1:1.5, the active component is a mixture of water-quenched slag and fly ash, and its mass accounts for 55% of the total weight of modified phosphogypsum and active components, The quality of fly ash accounts for 5% of the total weight of modified phosphogypsum and active components. The particle size of the loosened soil is 10-15mm, and the quality of the loosened soil is 9 times of the total weight of the modified phosphogypsum and the active components. The specific surface area of the phosphogypsum is 3600cm 2 / g, the specific surface area of the modifier is 3250cm 2 / g, the specific surface are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com