Blast furnace

A blast furnace and tuyere technology, applied in furnaces, shaft furnaces, vertical furnaces, etc., can solve problems such as tuyere blockage, furnace condition deterioration, and insufficient reaction, to achieve melting, increased fluidity, and full combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention provides a blast furnace for smelting copper, nickel and other non-ferrous metals. The blast furnace provided by the invention is beneficial to the uniform distribution of charge and fuel, improves the reaction conditions of the furnace, and enriches the non-ferrous metals in the ore with a recovery rate.

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

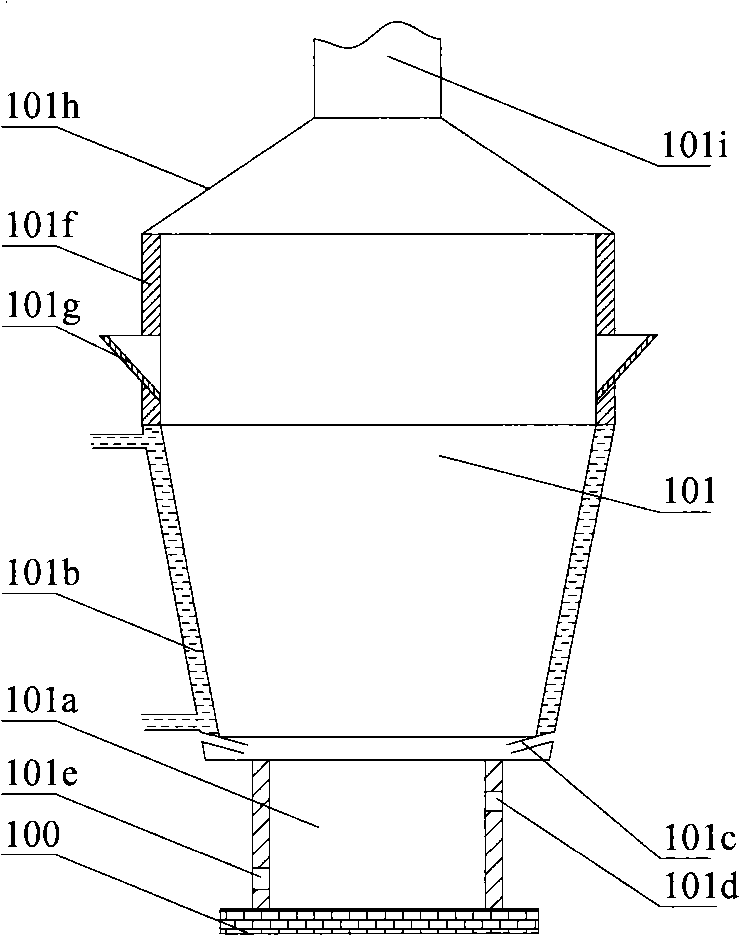

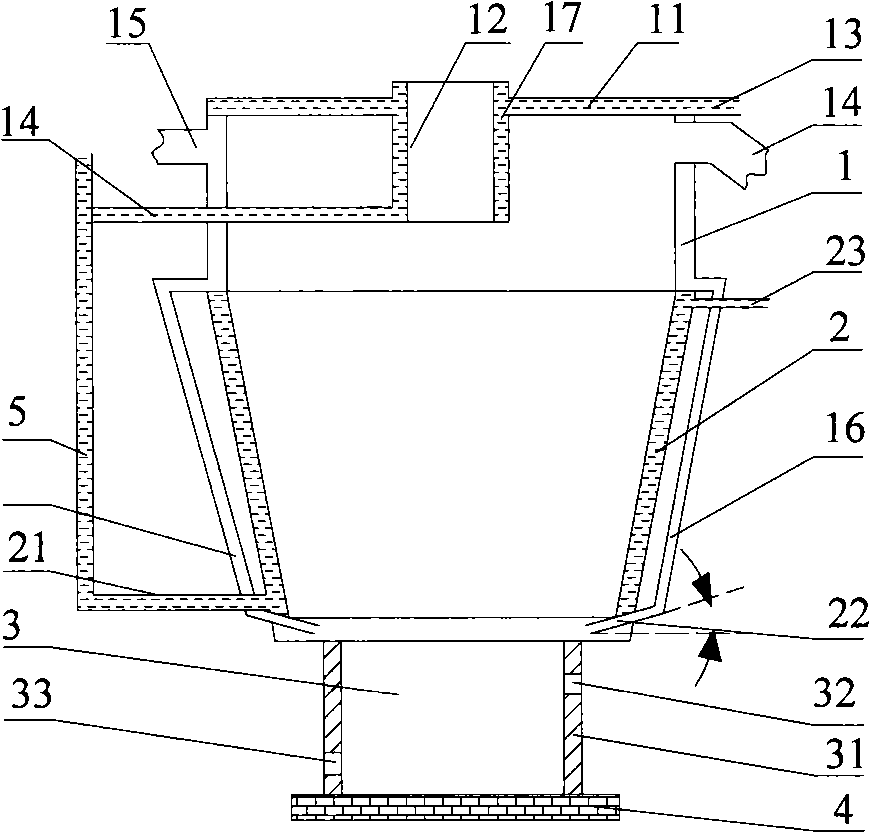

[0030] Please refer to figure 2 , figure 2 It is a structural schematic diagram of a specific embodiment of a blast furnace provided by the present invention. In a specific embodiment, the blast furnace provided by the present invention is installed vertically on the base 4, and the material of the base is refractory bricks. The blast furnace comprises a hearth 3, the hearth 3 comprises a vertical hearth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com