Controlling method for burdening of calcium carbide production

A control method, calcium carbide technology, applied in the direction of carbide, calcium carbide, etc., can solve the problems of large fluctuations in composition, low precision of ingredients, etc., to achieve the effect of ensuring taste and improving furnace conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

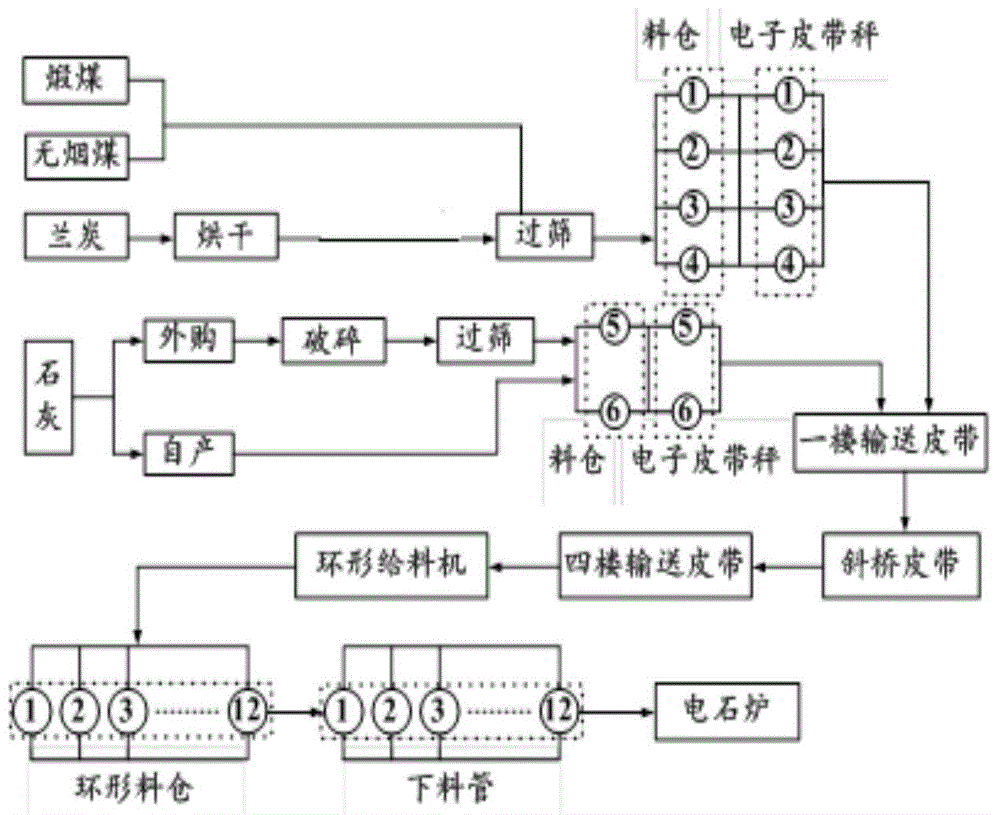

[0024] The present invention is aimed at calcium carbide production batching process flow ( figure 1 ) Calculate the material balance of the raw materials into the furnace, control the chemical composition of the raw materials into the furnace, so that the chemical composition of the raw materials into the furnace can not only meet the quality requirements for the production of calcium carbide, but also maintain the stability of the chemical composition of the raw materials into the furnace, so as to solve the ratio of calcium carbide production ingredients Problems with low accuracy and large fluctuations in composition. The specific process of this method is as follows:

[0025] 1. According to the relationship between the resistivity and air permeability of the mixture used for calcium carbide production and the particle size and ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com