Hot-rolled polyphase steel plate and method for manufacturing same

A steel plate and slab technology, applied in the direction of temperature control, etc., can solve the problems of steel cost increase, etc., and achieve the effects of short rolling cycle, economical composition design, and high rolling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

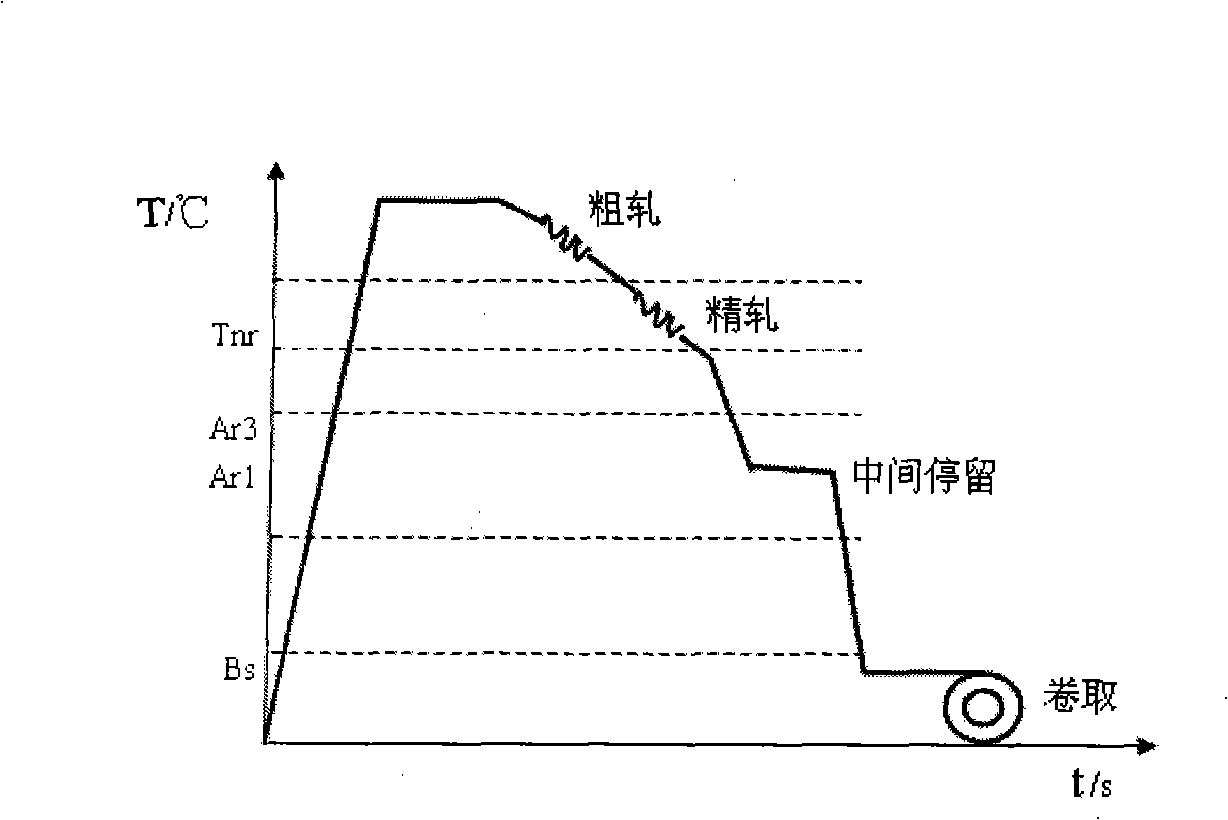

Method used

Image

Examples

Embodiment 1

[0047] Smelting and casting are carried out according to the chemical composition shown in Table 1 to form billets, and then the billets are heated to 1170°C. The thickness of the steel plate is 2.5mm. Rough rolling and hot deformation in the temperature range where austenite can recrystallize, and in the temperature range lower than austenite recrystallization but higher than the Ar3 transformation point, use one or more passes to fry the above steel plate to the final thickness of the steel plate. The finish rolling temperature was 800°C. Then enter the staged cooling process. The cooling rate in the first stage is 20°C / s, air cooling (intermediate stop) at 750°C for 10 seconds, the cooling rate in the second stage is 80°C / s, and the finished steel plate is obtained by cooling to the final cooling temperature of 230°C. Mechanical properties: see Table 11.

[0048] Table 1 Chemical composition of steel plate in Example 1

[0049]

Embodiment 2

[0051] Carry out steel plate manufacturing by the chemical composition shown in Table 2, manufacturing process is identical with embodiment 1. The billet heating temperature is 1170°C; the thickness of the steel plate is 3.0mm; the final rolling temperature is 820°C; the cooling rate in the first stage is 30°C / s, air cooling at 720°C (intermediate stay) for 6 seconds, and the cooling rate in the second stage is 58°C / s, has been cooled to the final cooling temperature of 330 ℃. Mechanical properties: see Table 11.

[0052] Table 2 The chemical composition of the steel plate in Example 2

[0053]

Embodiment 3

[0055] Steel sheets were manufactured with the chemical compositions shown in Table 3, and the manufacturing process was the same as in Example 1. The billet heating temperature is 1170°C; the steel plate thickness is 2.5mm; the finishing rolling temperature is 850°C; the cooling rate in the first stage is 40°C / s, air cooling at 689°C (intermediate stay) for 8 seconds, and the cooling rate in the second stage is 50°C / s, has been cooled to the final cooling temperature of 440 ℃. Mechanical properties: see Table 11.

[0056] Table 3 The chemical composition of the steel plate of Example 3

[0057]

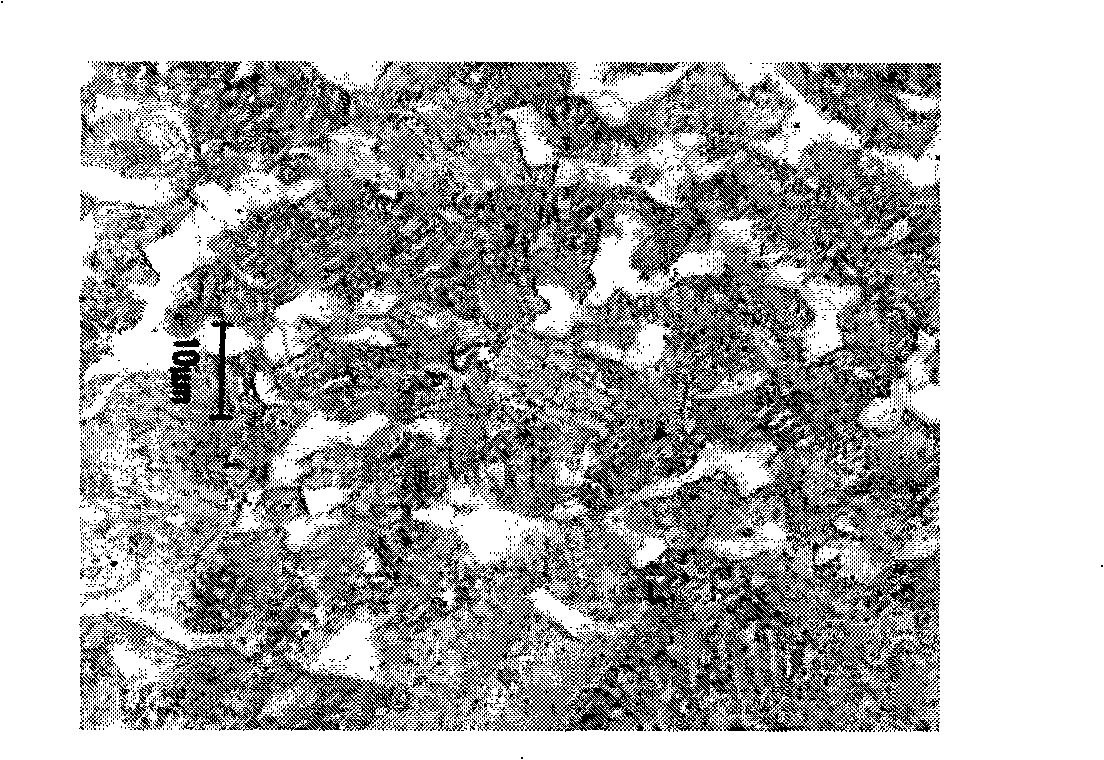

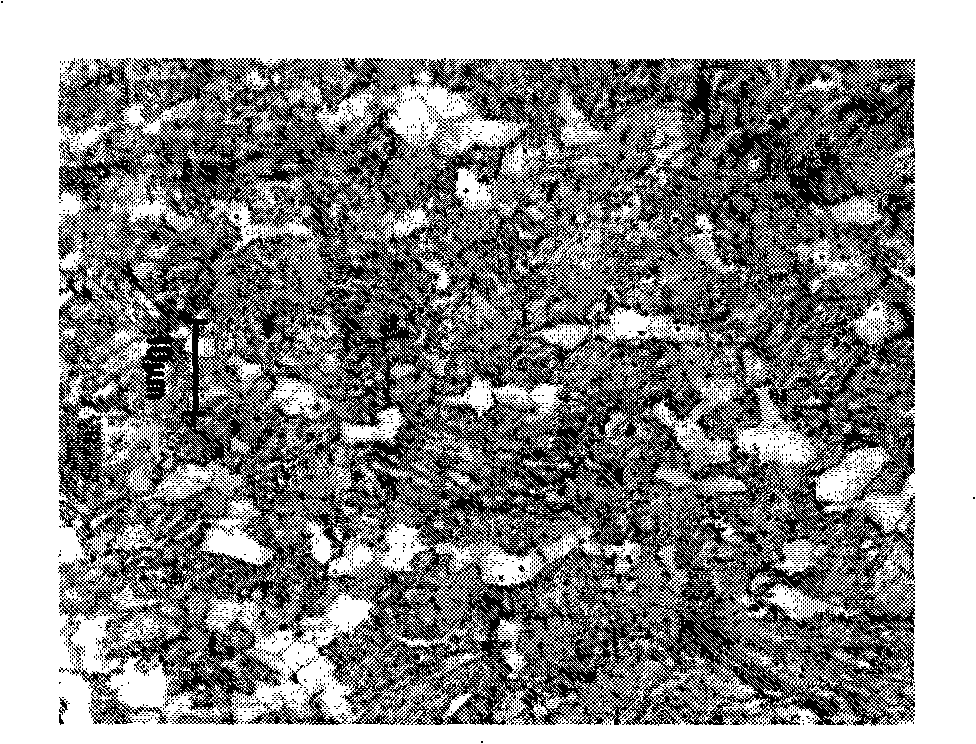

[0058] Example 3 The typical metallographic structure of the steel plate is shown in figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com