System and method for comprehensively utilizing cold energy of LNG

A cold energy and subsystem technology, applied in the field of LNG cold energy comprehensive utilization system, can solve the problems of unavailability, pressure fluctuation, low power generation efficiency, etc., and achieve the effect of increasing the difficulty of the process flow, saving refrigeration units, and reducing the cost of ice making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

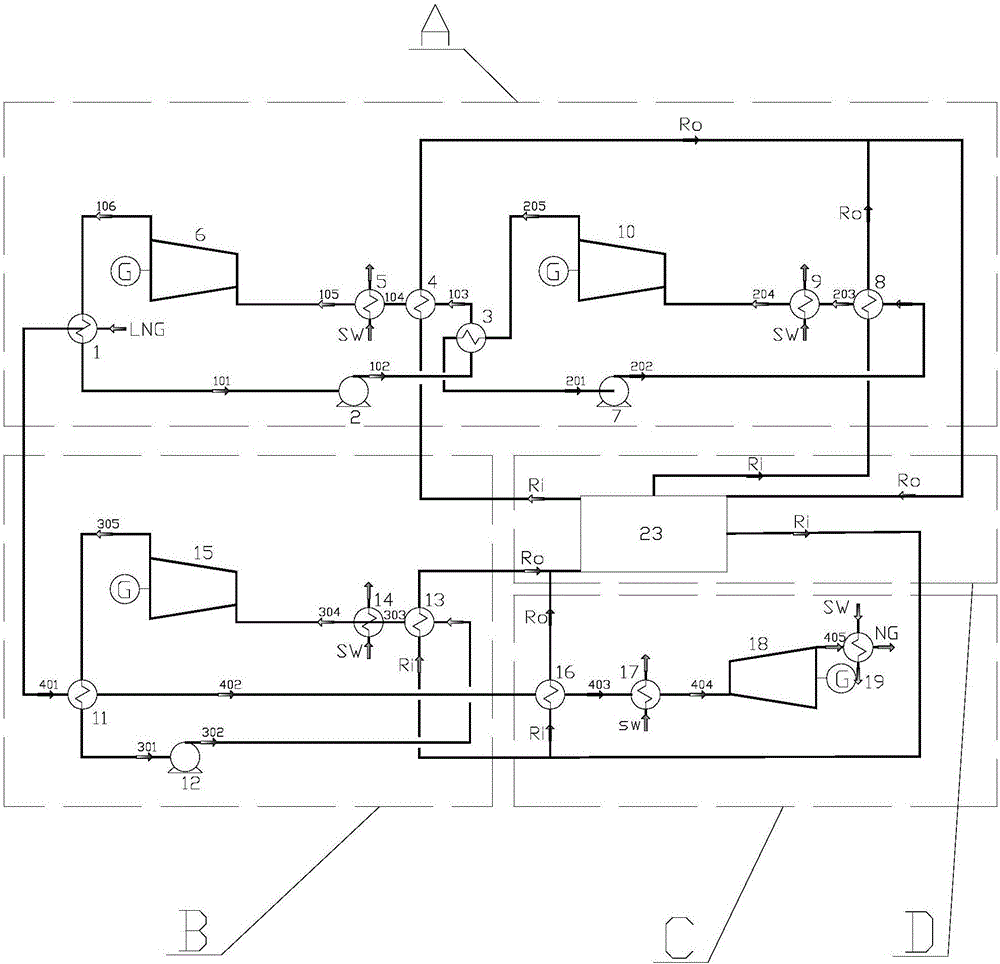

[0061] The liquefied natural gas cold energy comprehensive utilization system of this embodiment, such as figure 1 As shown, it includes composite Rankine cycle power generation subsystem A, simplex Rankine cycle power generation subsystem B, direct expansion power generation subsystem C and ice making subsystem D, wherein composite Rankine cycle power generation subsystem A includes LNG evaporator 1. Mixed working medium booster pump 2, heat exchanger 3, mixed working medium evaporator 4, mixed working medium superheater 5, mixed working medium expander 6, first single working medium booster pump 7, first simplex The medium evaporator 8, the first simple working medium superheater 9 and the first simple working medium expander 10, the mixed working medium expander 6 and the first simple working medium expander 10 are respectively connected to generators. The LNG evaporator 1 includes a first shell and a first heat exchange tube arranged in the first shell, the first shell has...

Embodiment 2

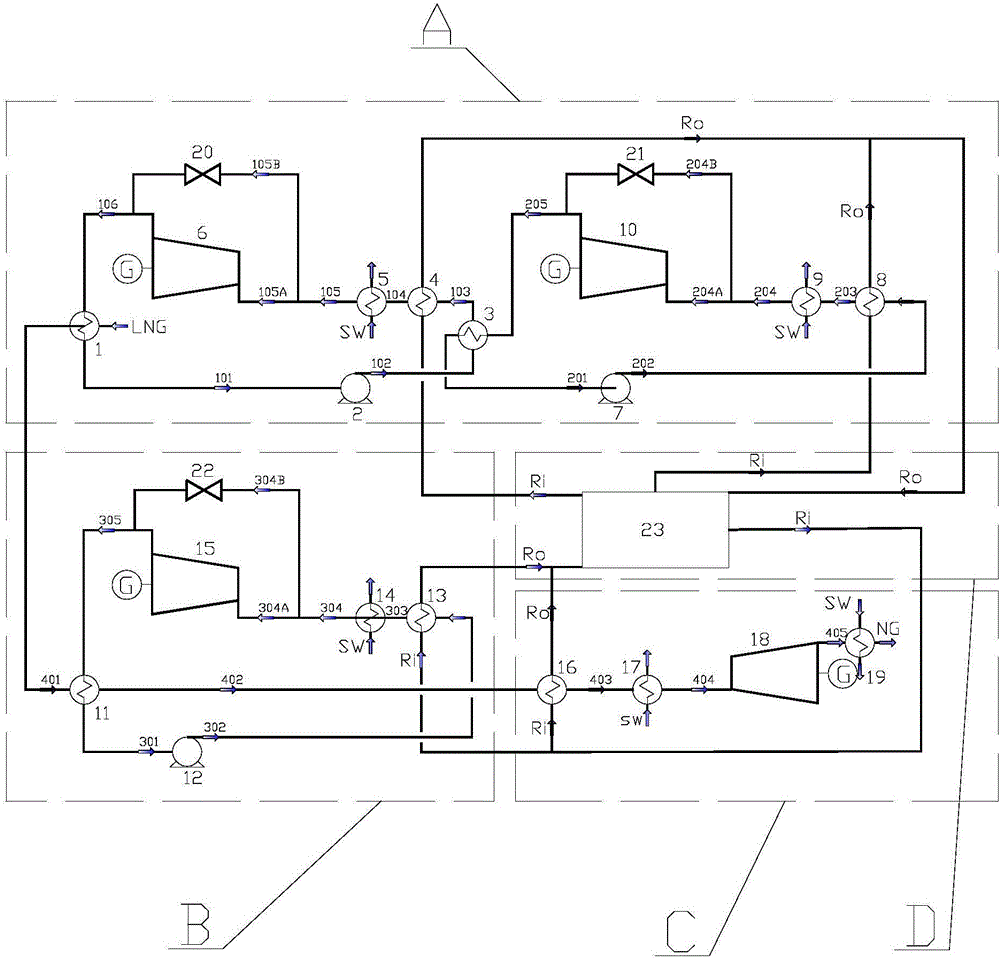

[0068] The difference between this embodiment and Embodiment 1 is that a first bypass pressure reducing valve 20 is installed between the inlet and outlet of the mixed working fluid expander 6, A second bypass decompression valve 21 is installed, and a third bypass decompression valve 22 is installed between the inlet and outlet of the second simplex expander 15 (see figure 2 ). A bypass is set in the expander of the Rankine cycle, and the flow direction of the working fluid is determined through the pressure reducing valve to ensure the independence of the system's vaporization function. Under normal power generation conditions, the working medium enters the expander, expands and generates power; when the expander is maintained or malfunctions, the pressure reducing valve is activated, and the working medium flows to the bypass, and the temperature and pressure of the working medium are lowered through the pressure reducing valve, and then according to The temperature and p...

Embodiment 3

[0070] The LNG parameters of a LNG receiving station are as follows: the flow rate is 150t / h, the temperature is -160°C, the pressure is 10MPa, and its composition (mol%) is 99% CH 4 , 1%C 2 h 6 . The seawater temperature is 7°C to 30°C. The network requirements of natural gas are as follows: flow rate is 150t / h, temperature is 0°C, pressure is 8.7MPa, and its composition (mol%) is 99% CH 4 , 1%C 2 h 6 .

[0071] The comprehensive utilization process of liquefied natural gas includes four parts: mixed working medium Rankine cycle power generation, first single working medium Rankine cycle power generation, second simple working medium Rankine cycle power generation, ice making and high pressure natural gas direct expansion power generation. The specific steps are as follows :

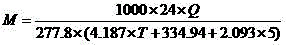

[0072] (1) Mixed working medium Rankine cycle power generation: the flow rate of the mixed working medium changes with the temperature of seawater, and the energy balance of the heat exchanger 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com