Planetary roller screw

A planetary roller and lead screw technology, which is applied to belts/chains/gears, mechanical equipment, transmission devices, etc., can solve problems such as not being suitable for high-speed operation, and achieve the effects of easy processing control, simple structure, and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

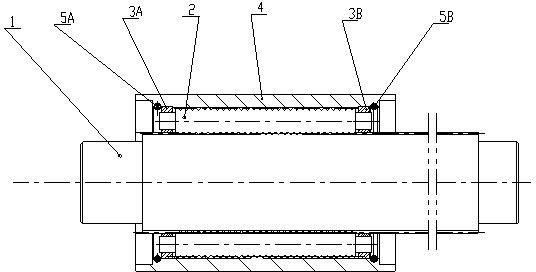

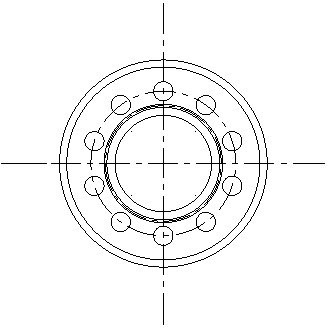

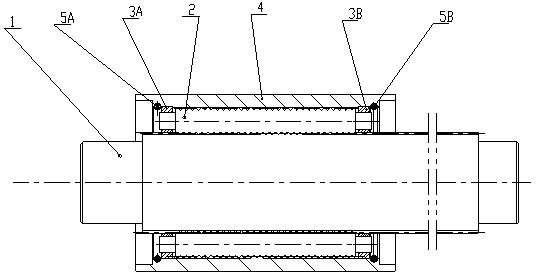

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] As shown in the figure, the new planetary roller screw consists of a screw 1, one or more rollers 2, a first roller planetary cage 3A, a second roller planetary cage 3B, a nut 4, a first stop The spacer ring 5A and the second limit spacer ring 5B are composed of the first and second roller planetary cages, the nut 4, the lead screw 1, and the first and second limit spacer rings. The roller planetary cage is set between the lead screw 1 and the nut 4; the end of each roller is movably set in the installation hole of the roller planetary cage; the limit spacer ring can be fixedly connected to the nut 4. The thread of screw 1 is single or multi-thread (three to eight threads), and the thread of one or more rollers 2 (usually 6-12 according to different specifications) is one or two kinds of leads. The thread teeth of the roller 2 are matched with each other and pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com