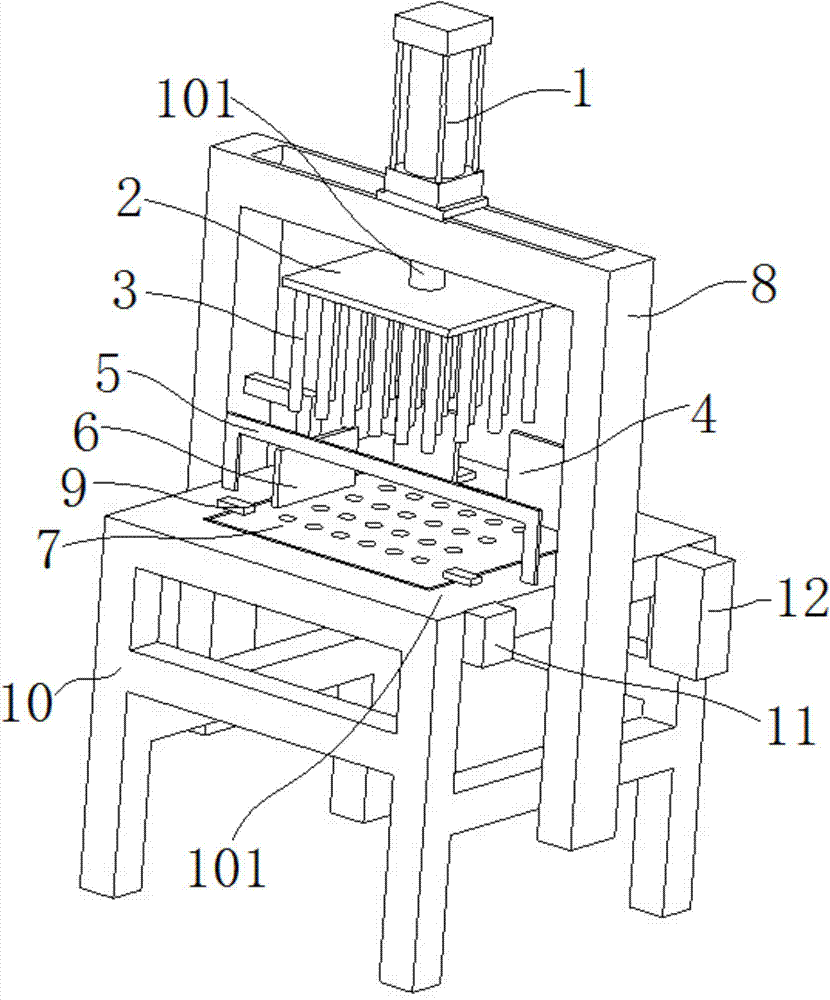

Pneumatic punching machine

A pneumatic punching and punching technology, which is applied in metal processing and other directions, can solve the problems of ignoring the positioning of stamped parts, and achieve the effects of high work efficiency, accurate placement, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

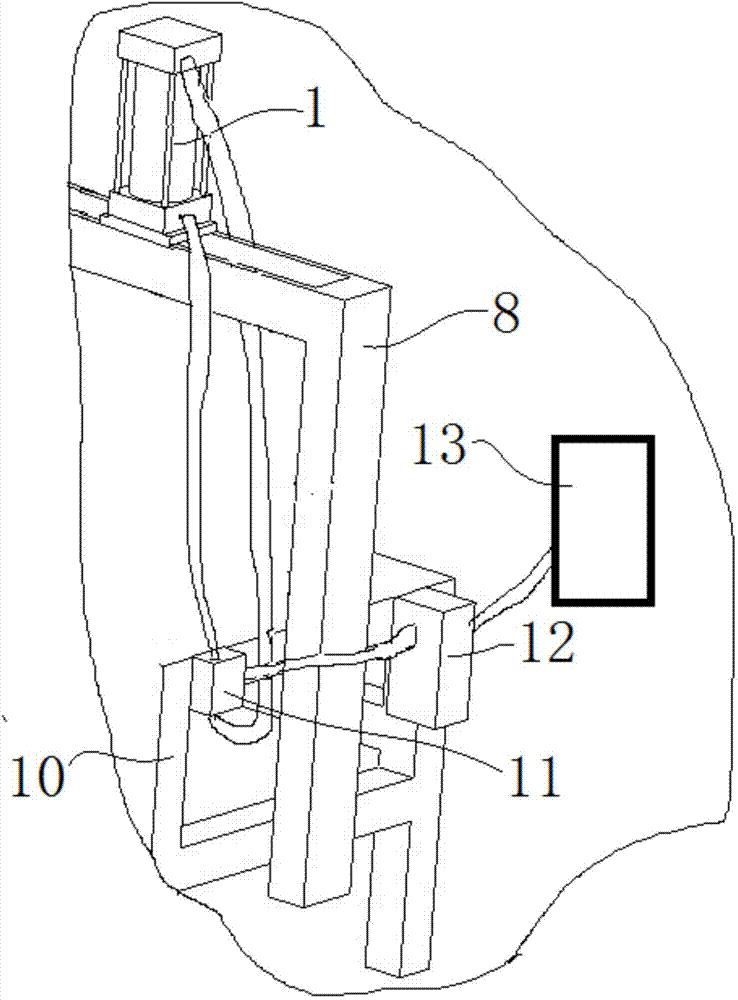

[0025] combine figure 1 and figure 2 , a pneumatic punching machine of the present embodiment, comprising an upper template 2, a punch 3, a bolt locking mechanism 10, a workbench 9, a manual reversing valve 11 fixed on the side of the workbench 9, and a manual reversing valve fixed on the side of the workbench 9 The pressure regulating valve 12 and the positioning device, the upper part of the workbench 9 is the work platform 901; the work platform 901 is embedded with a die 7, and the die 7 is fixed on the workbench 9 through the bolt locking mechanism 10, so that the installation is stable , and it is easy to disassemble; a positioning device for positioning the stamped part is fixed on the working platform 901, which makes the placement of the stamped part more accurate, reduces the stamping error rate, and saves costs; the positioning device includes a positioning device for positioning the width of the stamped part The first positioning piece 4 in the direction, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com