Electrode frame structure for redox flow cell

A liquid flow battery and electrode frame technology, which is applied to fuel cell components, fuel cells, circuits, etc., can solve problems affecting battery efficiency and life, loss of protection, and easy deformation, so as to prolong life and avoid electric shocks. Chemical corrosion, the effect of easy assembly in piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

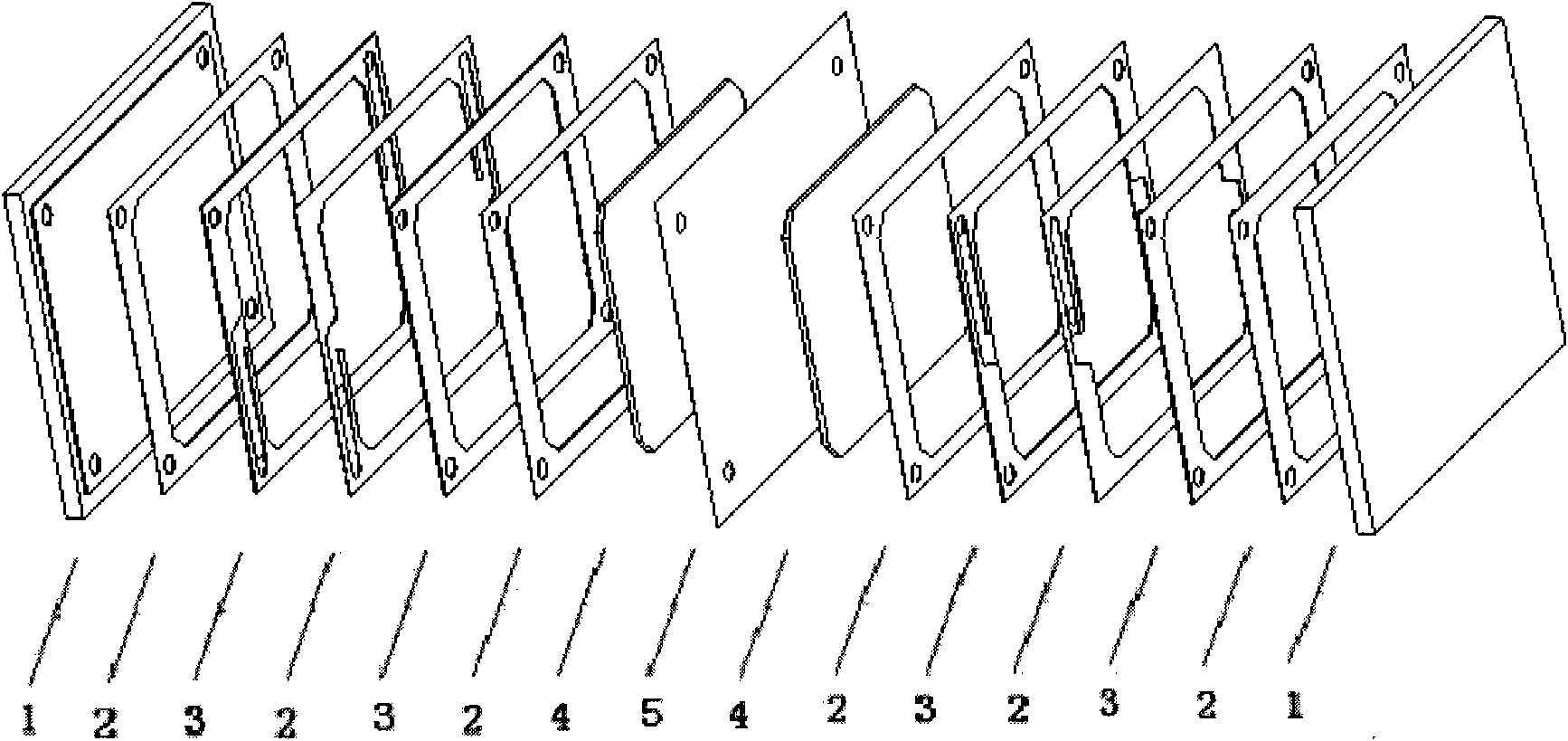

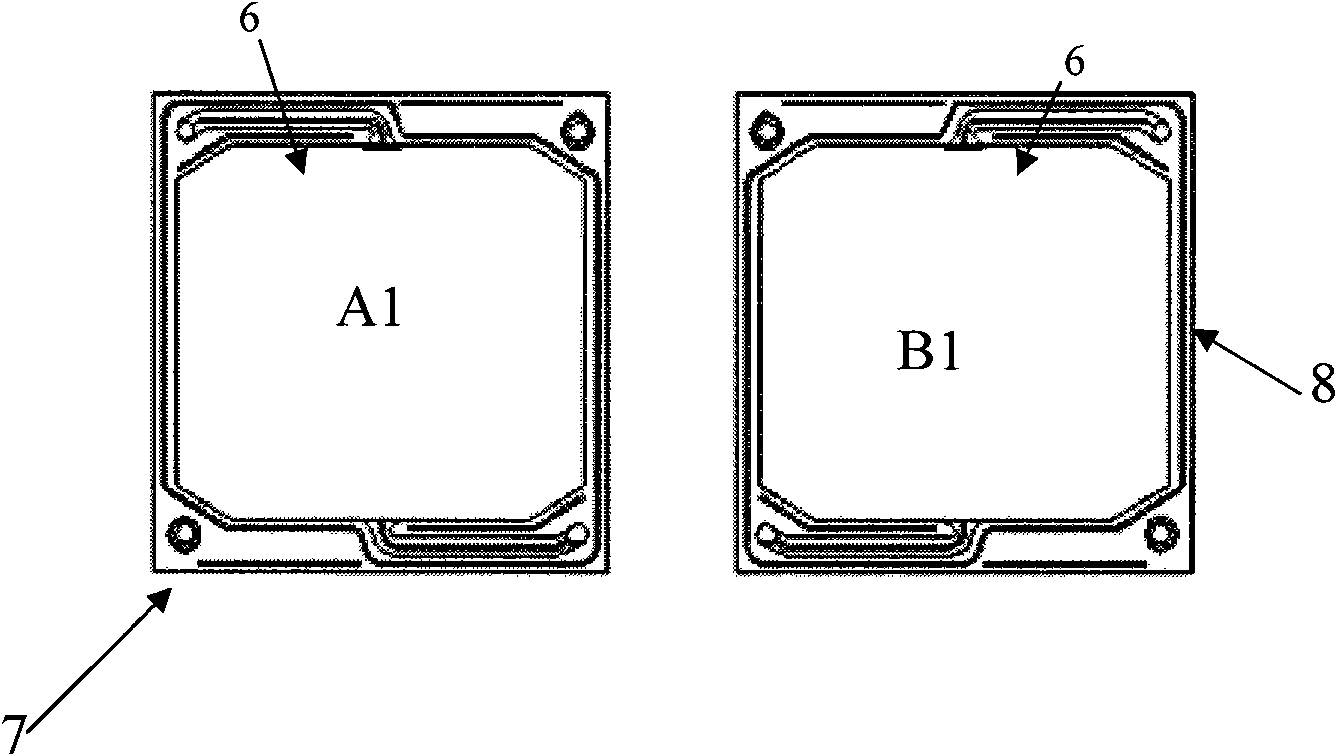

[0023] Battery structure such as figure 1 As shown, the electrode frame is as figure 2 As shown, it is a built-in fluid flow channel formed by two square frames (A1 and B1) having mirror-symmetrical fluid flow channels, and the fluid channels are buckled together inwardly. Two square frames are glued together to form a built-in structure. The frame material is PVC.

[0024] Dimensions of the electrode frame: length 300cm, width 400cm

[0025] Electrode area: 875cm2

[0026] Number of single batteries: 13

[0027] Stack charge and discharge voltage efficiency 89%, coulombic efficiency 90.5%, energy efficiency 80.5%

Embodiment 2

[0029] Battery structure such as figure 1 As shown, the electrode frame is as figure 2 As shown, it is a built-in fluid flow channel formed by two square frames (A1 and B1) having mirror-symmetrical fluid flow channels, and the fluid channels are buckled together inwardly. The two boxes are sealed with sealing material and face-sealed, and a built-in structure is formed through assembly force. The sealing material is fluorine rubber, and the frame material is PE.

[0030] Dimensions of the electrode frame: length 400cm, width 500cm

[0031] Electrode area: 1700cm2

[0032] Number of batteries: 15

[0033] The charging and discharging voltage efficiency of the stack is 87%, the Coulombic efficiency is 93.5%, and the energy efficiency is 81.4%.

Embodiment 3

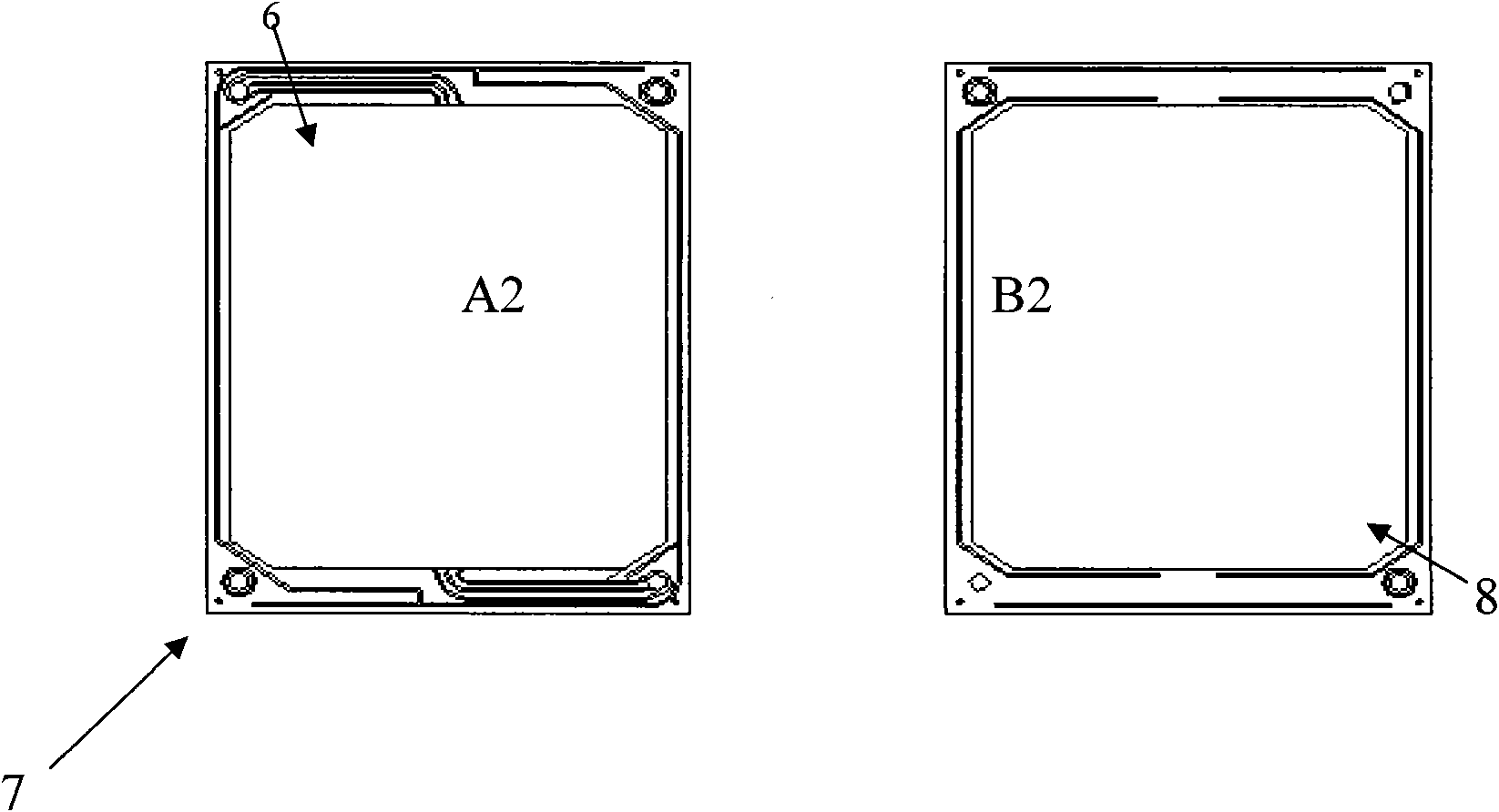

[0035] Battery structure such as figure 1 As shown, the electrode frame is as image 3 As shown, it is composed of two square frames with the same shape and size (A2 and B2), where the A2 frame is engraved with inlet and outlet flow channels, while the B2 frame has no engraved fluid flow channels, and the A2 frame The flow channel is inwardly buckled with the B2 frame to form a built-in fluid flow channel. The two boxes are sealed with sealing material and face-sealed, and a built-in structure is formed through assembly force. The sealing material is fluorine rubber, and the frame material is PP.

[0036] Dimensions of the electrode frame: length 400cm, width 500cm

[0037] Electrode area: 1700cm2

[0038] Number of batteries: 20

[0039] The charging and discharging voltage efficiency of the stack is 89%, the Coulombic efficiency is 91.5%, and the energy efficiency is 81.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com