Water pressure test device for junction box of explosion-proof motor

A technology for hydrostatic testing and explosion-proof motors, which is applied to measuring devices, measuring device casings, instruments, etc., can solve the problems of inability to ensure the sealing effect of the junction box cover and junction box seat, long manufacturing cycle, and inconvenient hydrostatic testing. The effect of low processing difficulty, convenient purchase and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

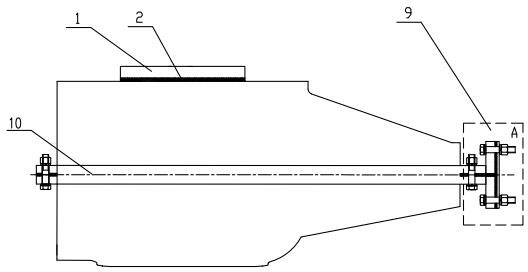

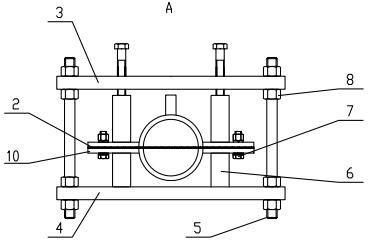

[0014] In order to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. However, the accompanying drawings are only provided for reference and illustration and are not used to limit the present invention.

[0015] Such as figure 1 As shown, the hydraulic test device for the explosion-proof motor junction box of the present invention includes a pressure plate 1, a sealing gasket 2, an upper pressure plate 3, a lower pressure plate 4, a connecting screw 5, a pressure block 6, a bolt 7 and a nut 8. The pressure plate 1 is pressed between the inner lead hole (that is, the upper surface) of the junction box and the power interface hole (that is, the plane of the end of the base), and the pressure plate 1 has holes that match the junction box for connection, fastening, and sealing. The gasket 2 is placed between the explosion-proof surface 10 of the junction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com