Patents

Literature

285results about How to "Reduce cost waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

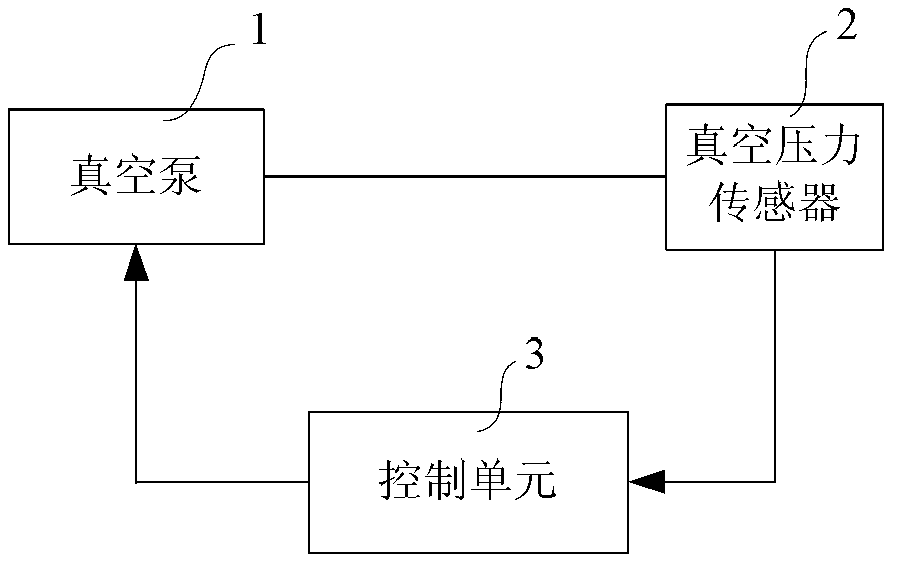

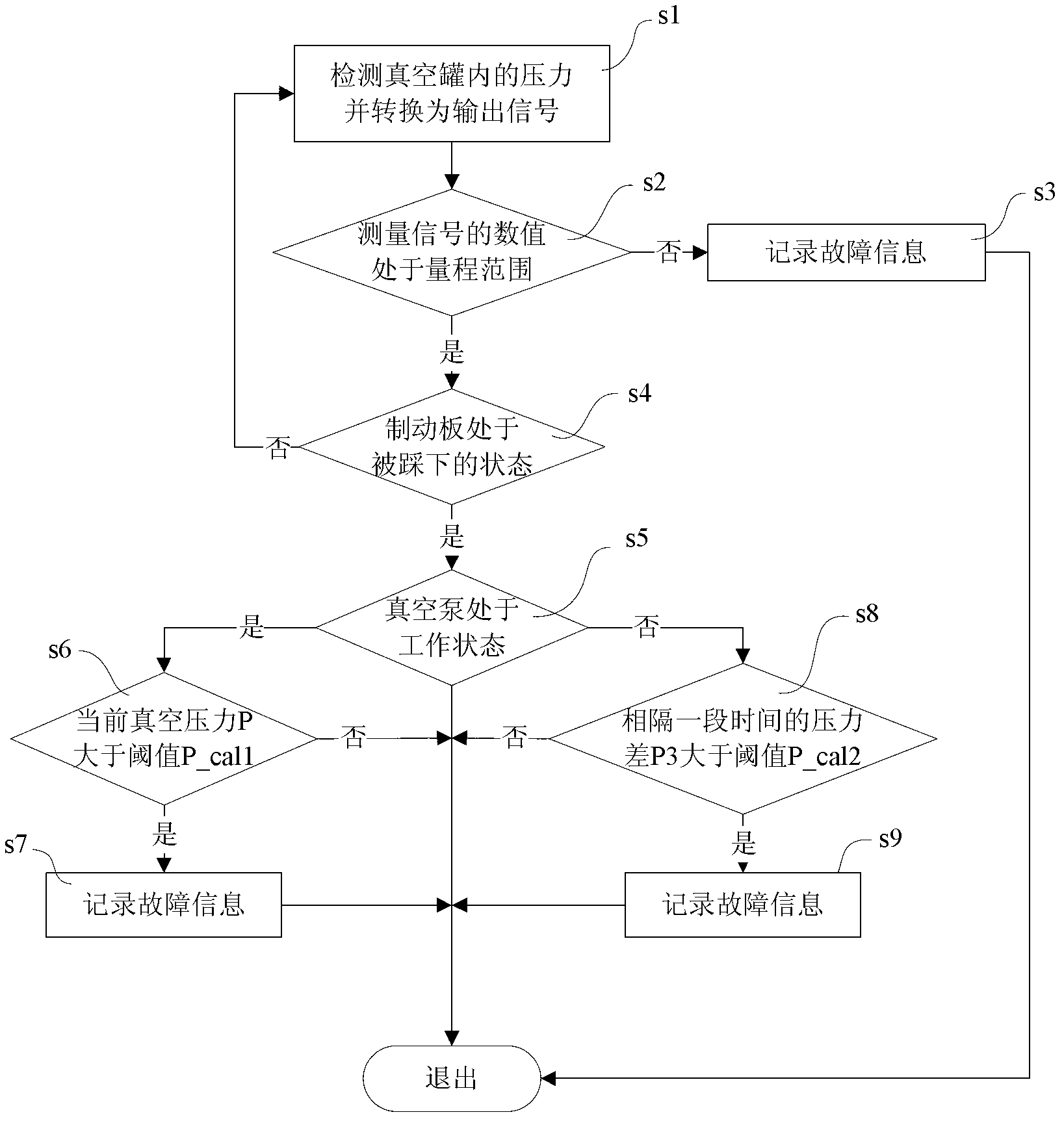

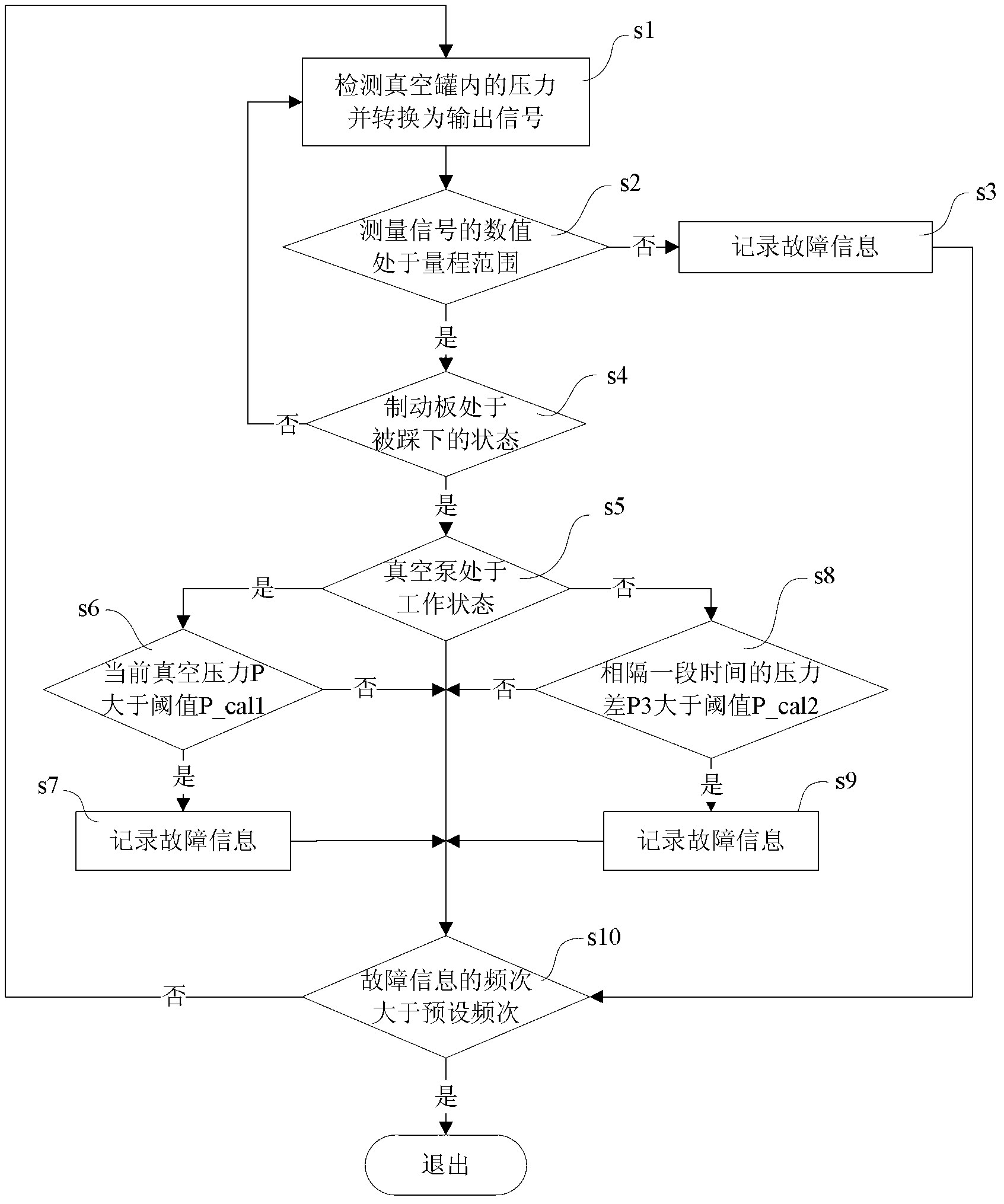

Vacuum assistance system detection method, vacuum assistance system detection system, electromobile and failure detection method

ActiveCN103318165AAvoid the problem of working all the timeImprove reliabilityBrake safety systemsVacuum pumpVacuum Assistance

The invention provides a vacuum assistance system detection method, a vacuum assistance system detection system, an electromobile and a failure detection method. The vacuum assistance system detection method includes the following steps: judging whether a pressure sensor fails or not; after the pressure sensor is guaranteed to be not in a failure, further diagnosing whether a vacuum pump is noneffective or not or whether a vacuum assistance system is in air leakage or not according to accurate measuring signals output by the pressure sensor. By the vacuum assistance system detection method, the vacuum assistance system can be detected accurately and comprehensively, and once the vacuum assistance system fails, failure positions can be quickly judged, so that reliability of the vacuum assistance system is effectively improved and driving safety of the electromobile is guaranteed.

Owner:奇瑞新能源汽车股份有限公司

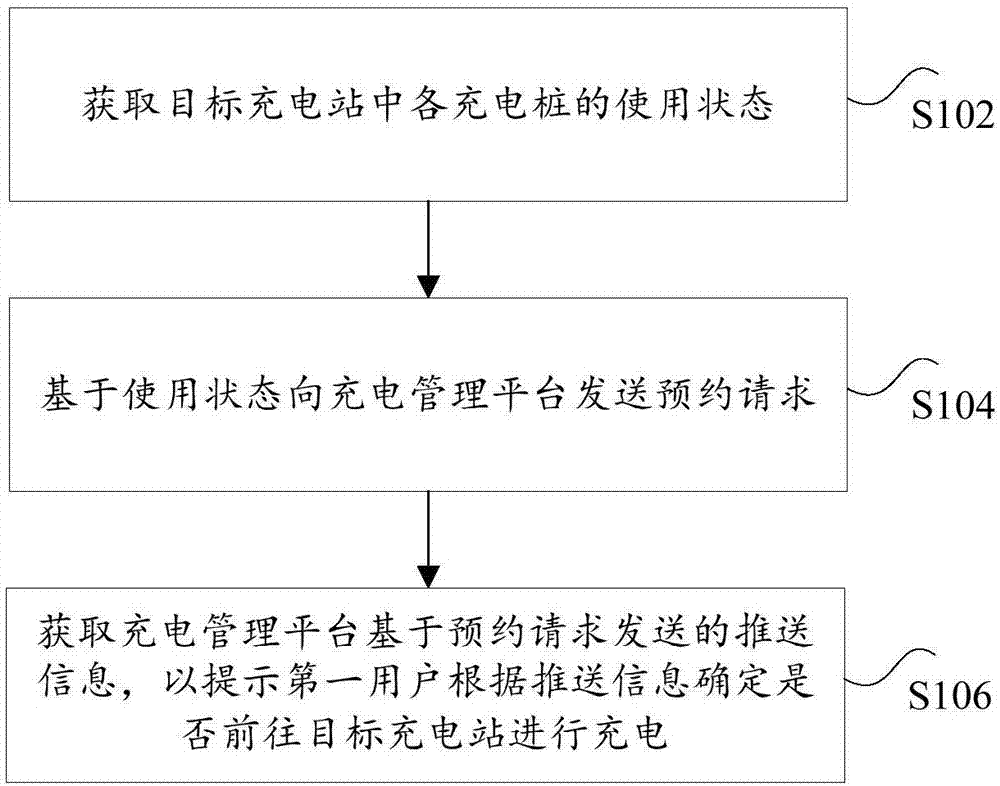

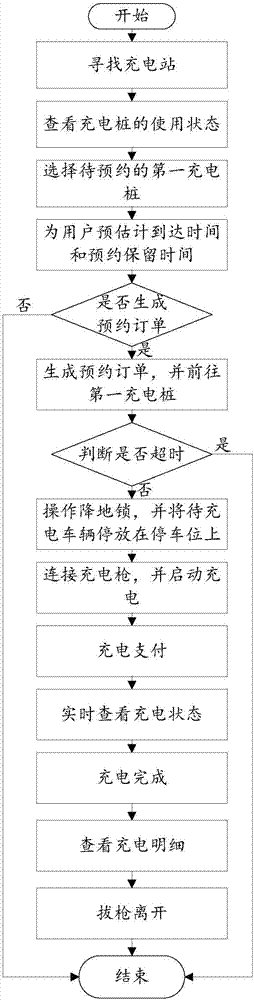

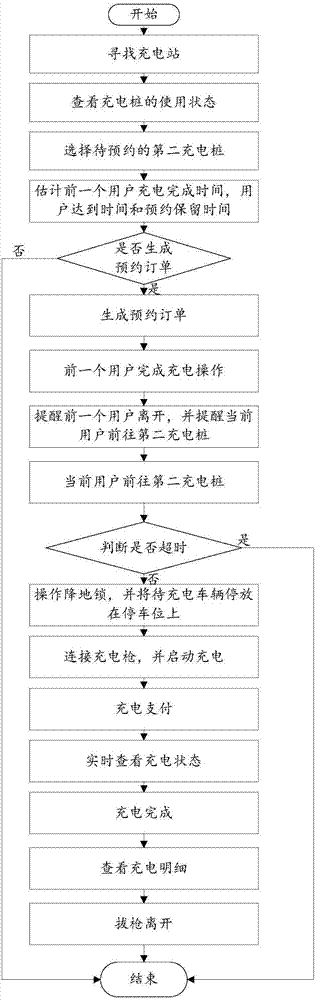

Charging control method, device and system for charging pile

InactiveCN107423832AReduce investmentAutomate the processTicket-issuing apparatusCharging stationsParking spaceCharge control

The invention provides a charging control method, a device and a system for a charging pile, which relate to the technical field of charging piles. The method comprises steps: the use state of a charging pile in a target charging station is acquired; based on the use state, a reservation request is sent to a charging management platform, wherein the reservation request represents the target charging pile in the target charging station is requested to be reserved; and pushing information sent by the charging management platform based on the reservation request is acquired to prompt a first user to decide whether to advance to the target charging station for charging according to the pushing information, when the first user advances to the target charging pile for charging, an intelligent ground lock of the target charging pile is unlocked through the charging management platform and thus, charging operation is executed. Thus, the technical problems of large manpower investment and low coverage when the existing way is used to solve the problem of the occupancy of parking space resources in charging facilities can be alleviated.

Owner:WANBANG CHARGING EQUIP CO LTD

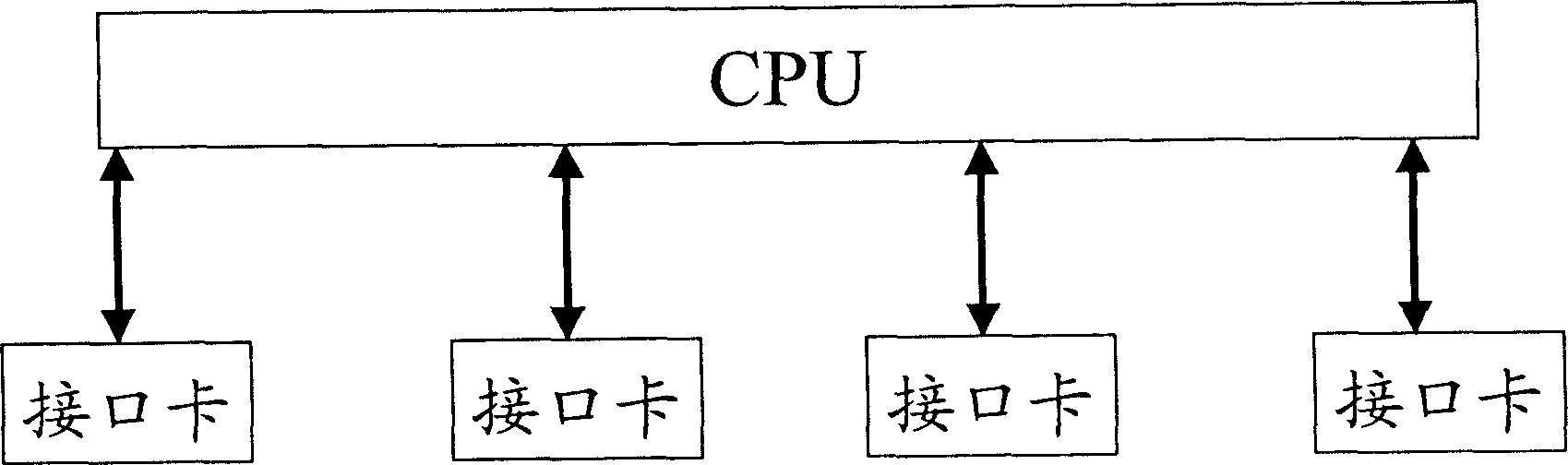

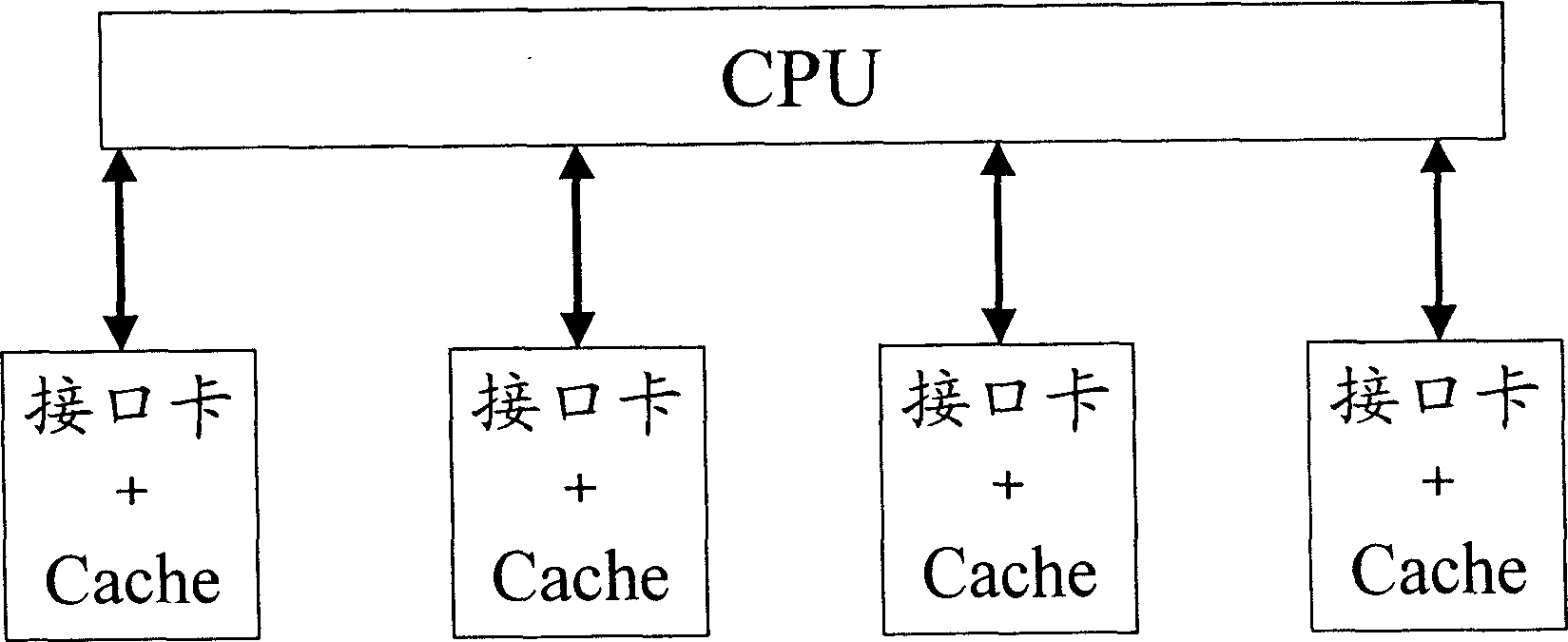

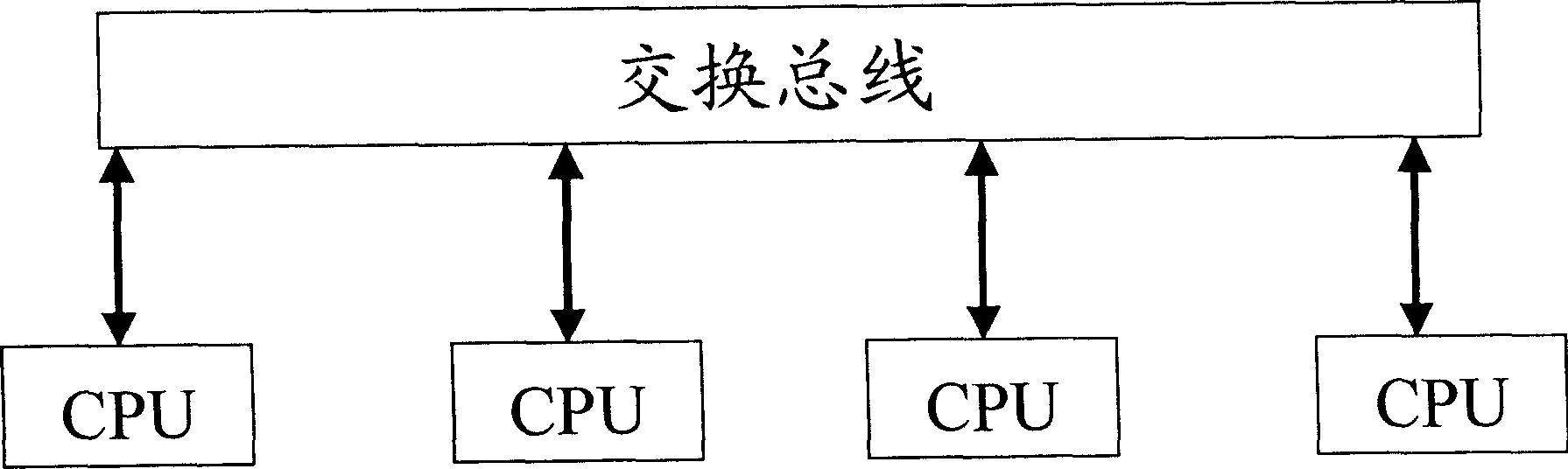

Network processor

ActiveCN1885822AGuaranteed reliabilitySolving problems that business functions will affect performanceData switching networksComputer hardwareNetwork processor

The disclosed network processor comprises: an ASIC module integrated one or more main transmission hardware pipeline for message, and a micro-engine module with one or more programmable micro-engines for software-assist transmission, yes to notify the micro-engine module for process, or else takes main transmission directly, wherein the ASIC module uses a decision part connected to the micro-engine module to decide whether need the latter for assist transmission. This invention has high flexibility and reliability.

Owner:HUAWEI TECH CO LTD

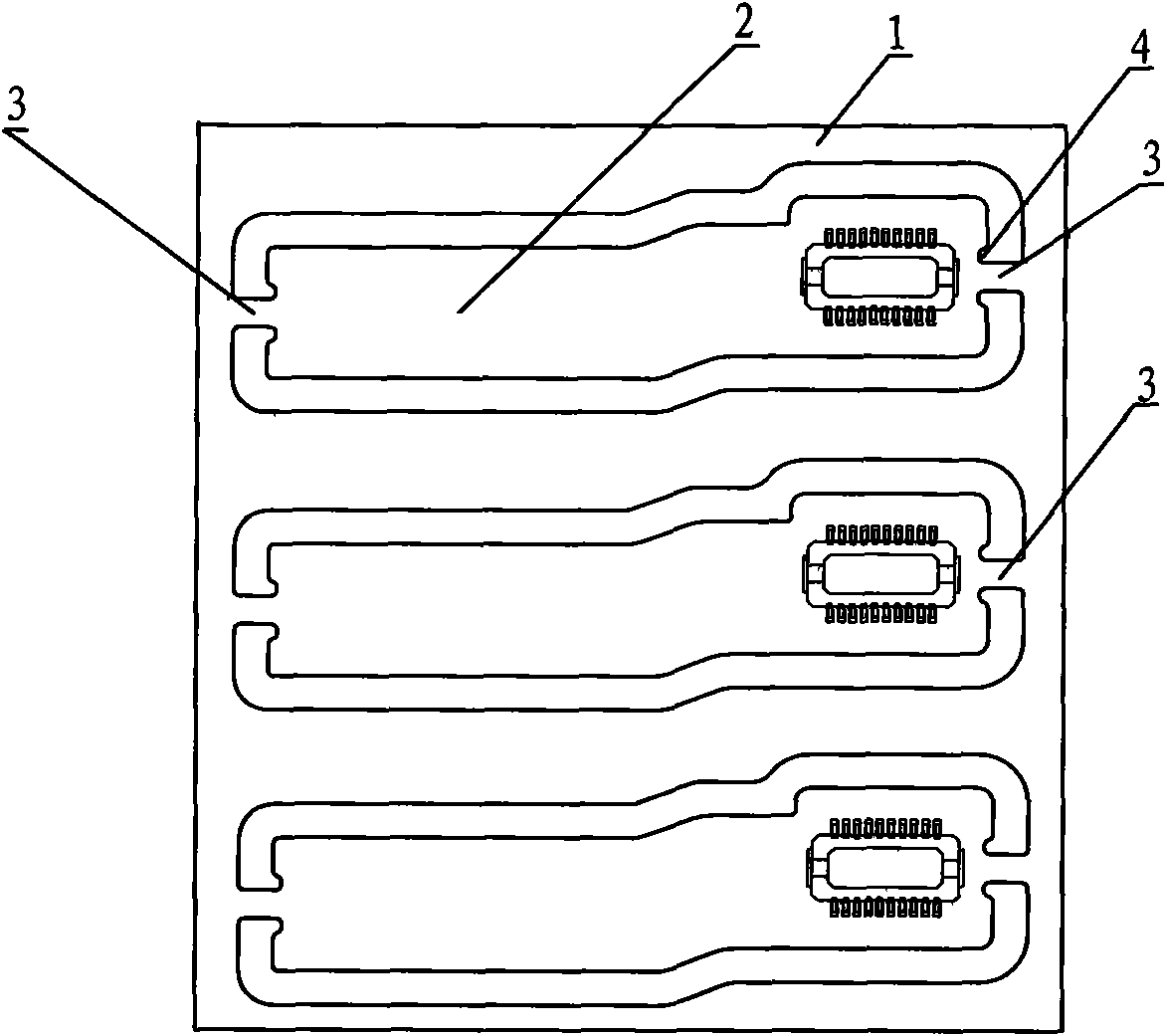

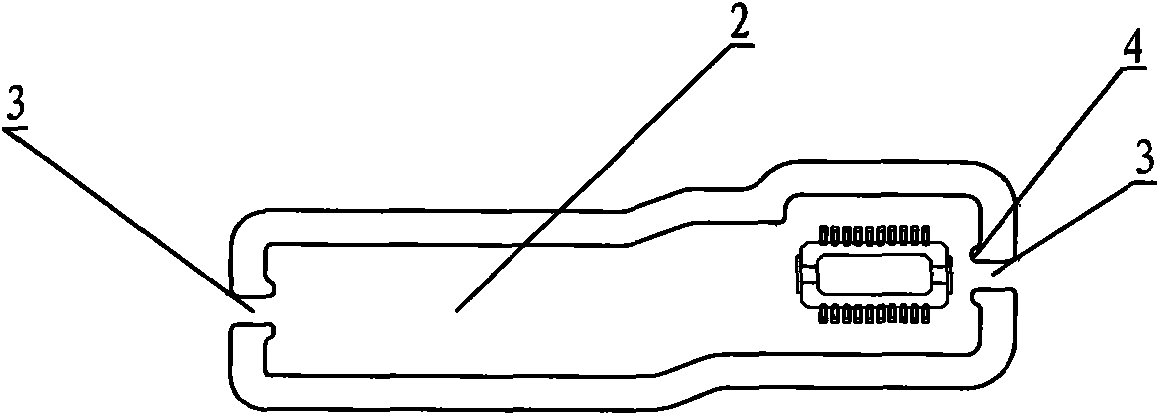

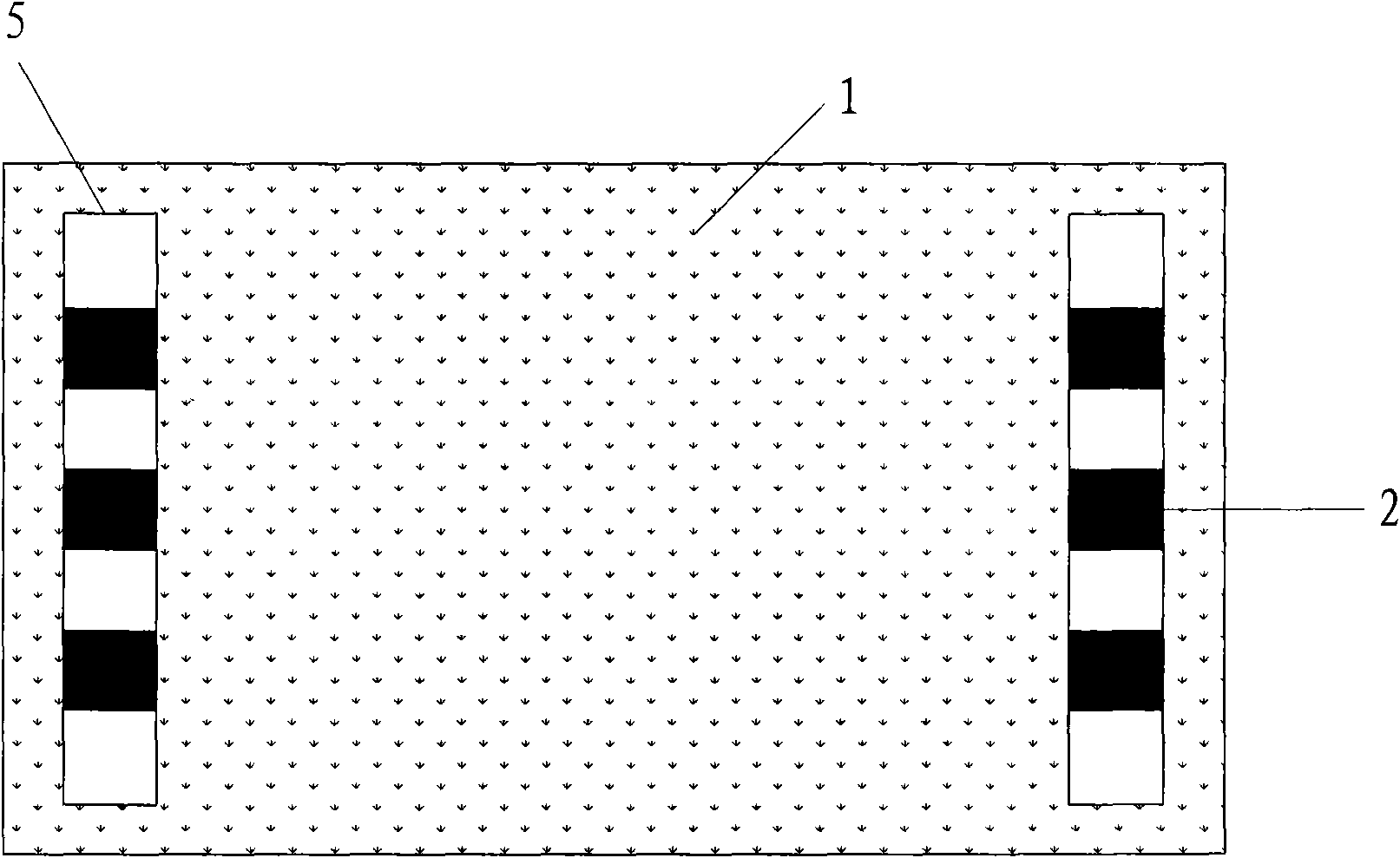

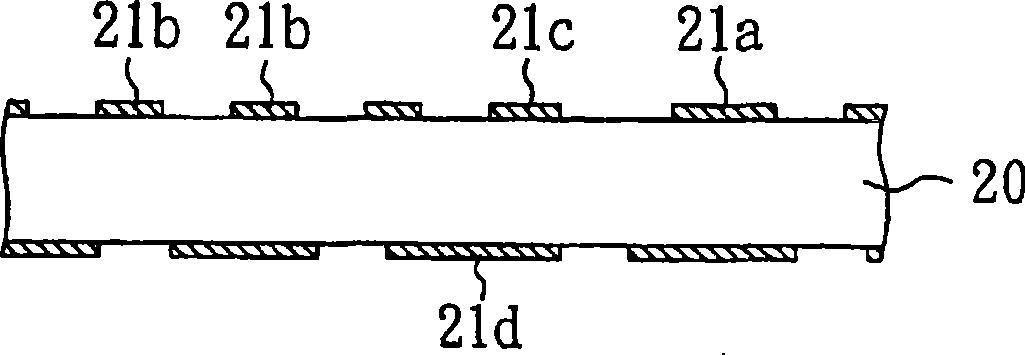

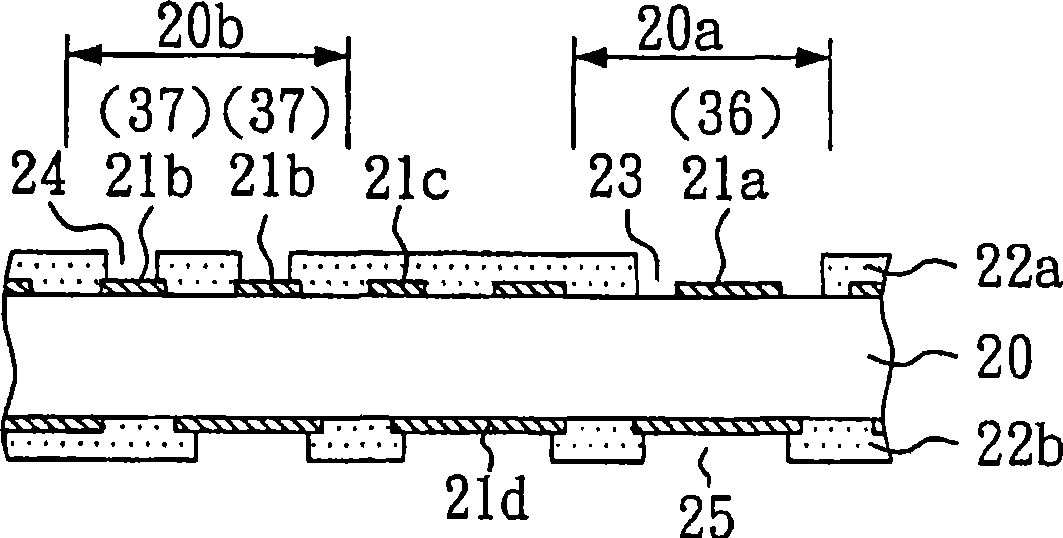

Flexible printed circuit whole board punching method

ActiveCN101686604AImprove yieldReduce cost wastePrinted circuit manufactureMetal working apparatusPunchingEngineering

The invention provides a flexible printed circuit whole board punching method, the method adopts a flexible printed circuit whole board, a first mould and a second mould; wherein the first mould comprises at least one first punch head compatible to the shape of the flexible printed circuit; the second mould comprises at least one second punch head used for punching the joint part of the flexible printed circuit; the joint part comprises at least one groove the two sides of which are lower than the shape of product. The method includes that the flexible printed circuit whole board is fed into the processing area of the first mould and the first punch head is utilized to punch the shape of the circuit board; the second punch head of the second mould is used for punching the joint part of theflexible printed circuit, thus forming the flexible printed circuit. The flexible printed circuit whole board punching method of the invention adopts the punch head of the first mould to punch the shape of flexible printed circuit board product, then the punch head of the second mould is used for punching the joint part of the flexible printed circuit, thus not only improving yield of products, but also reducing unnecessary cost waste, thereby being beneficial for product assembly.

Owner:深圳市合力泰光电有限公司

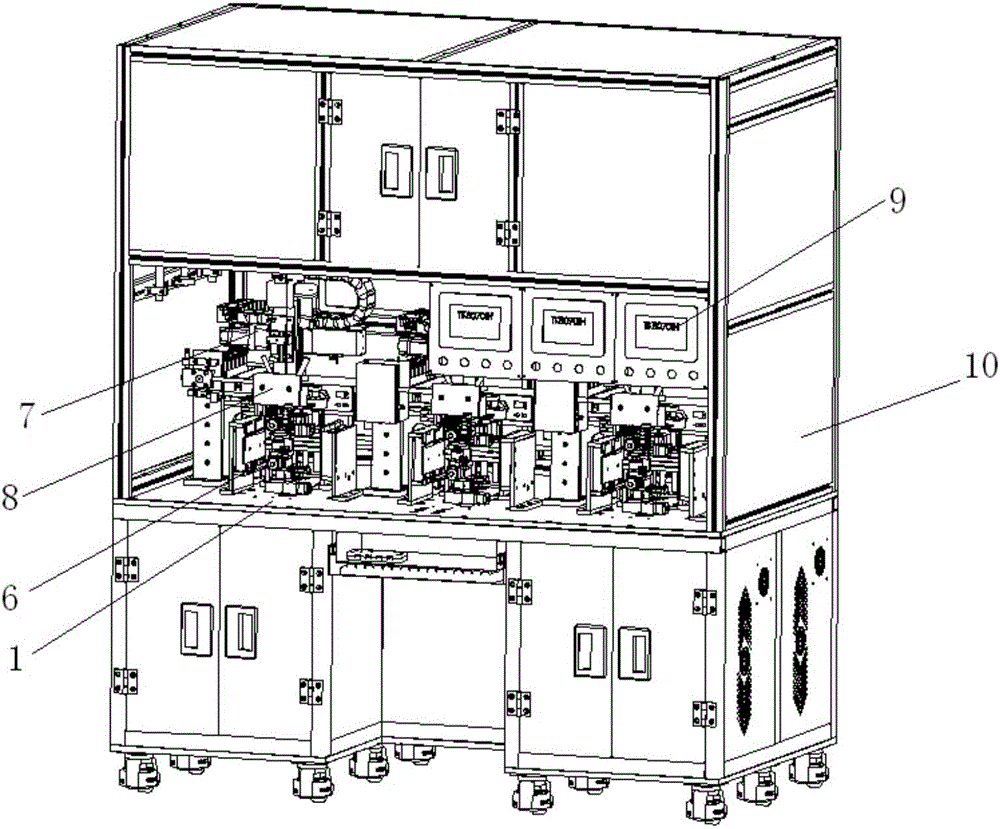

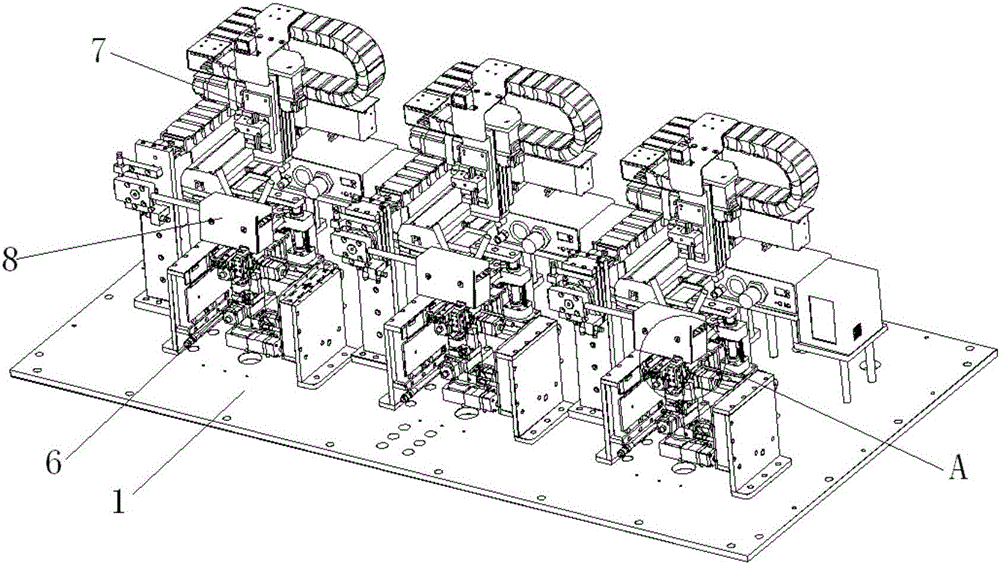

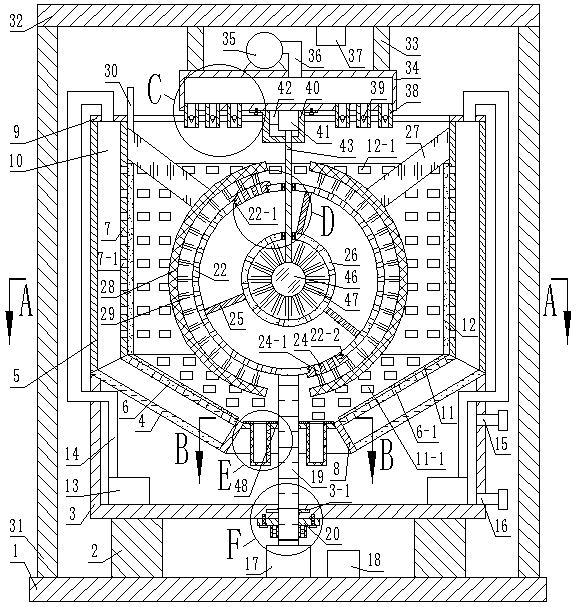

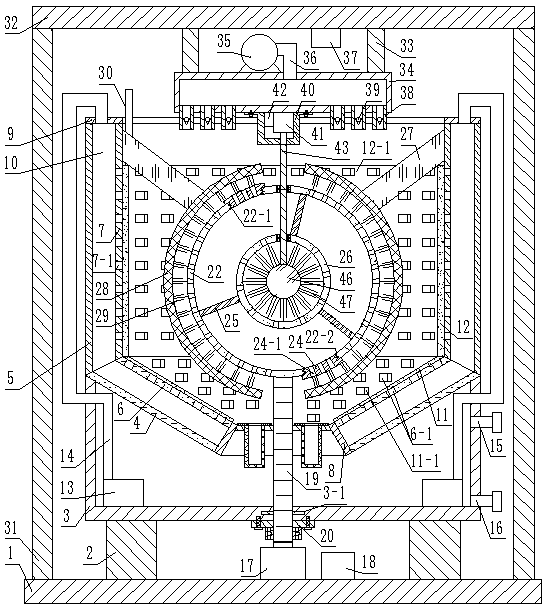

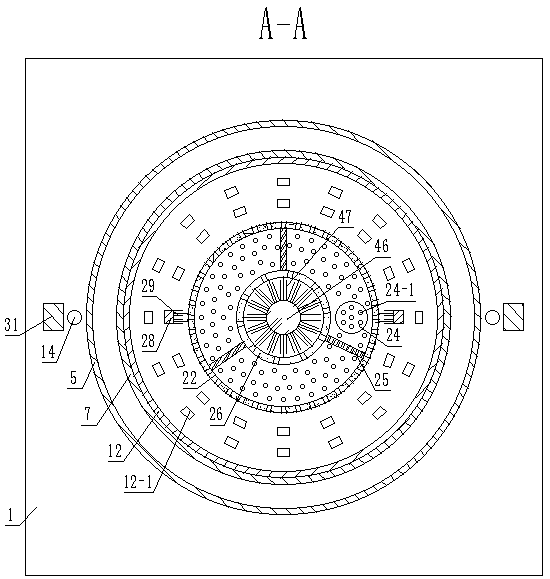

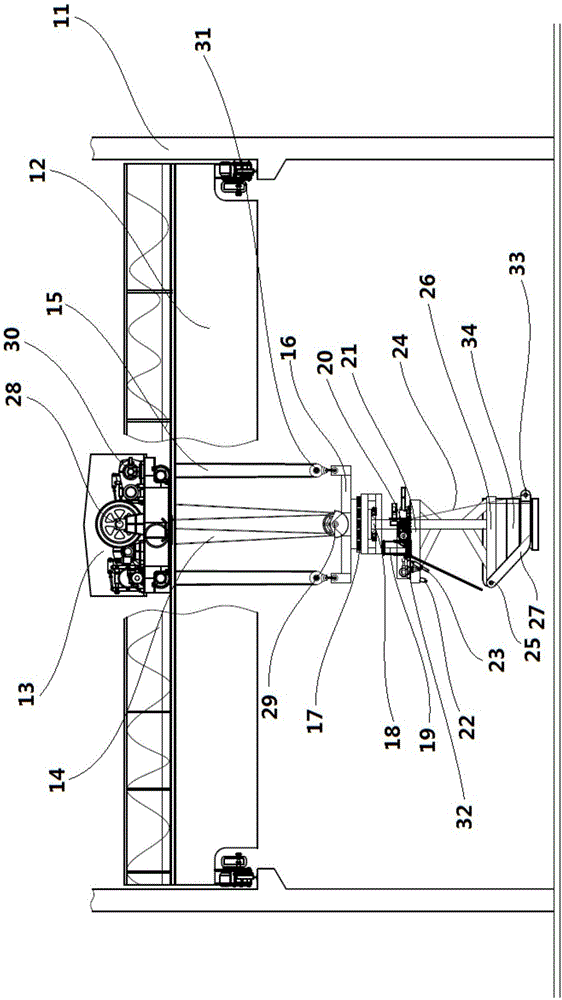

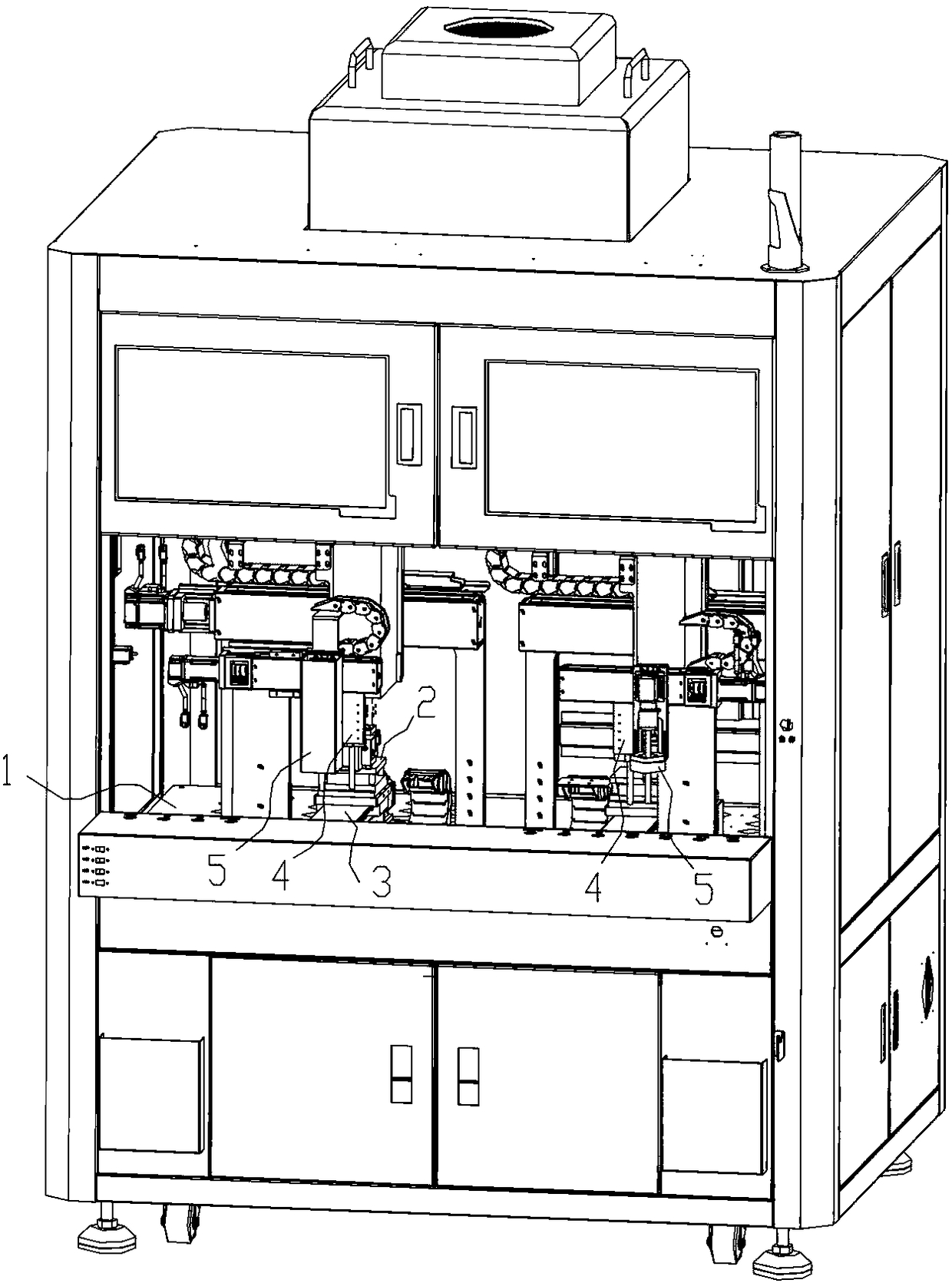

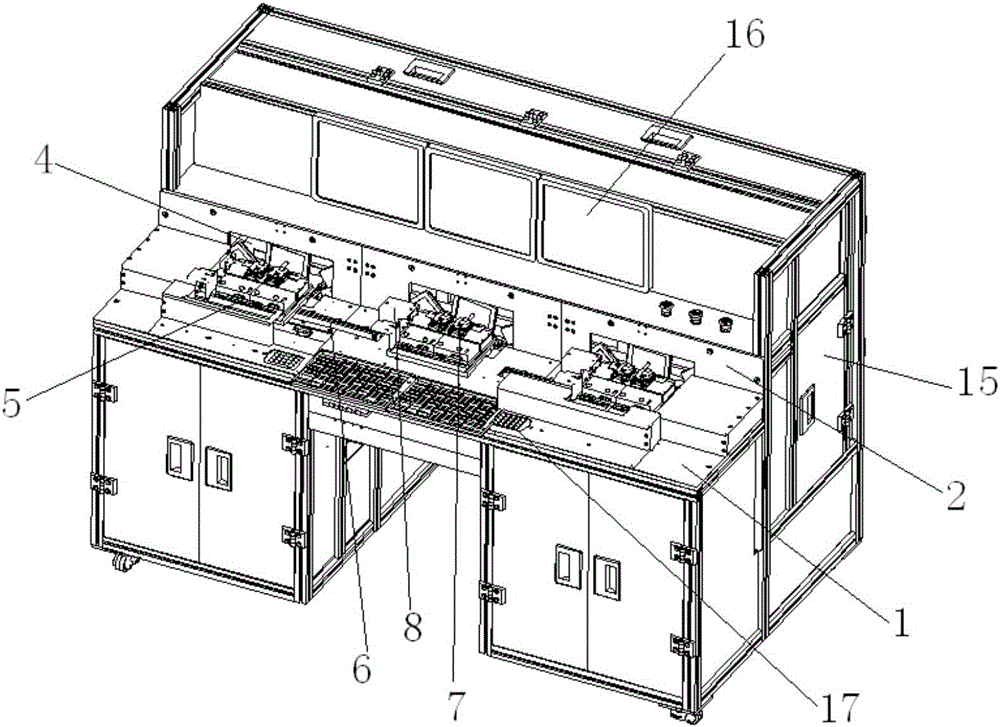

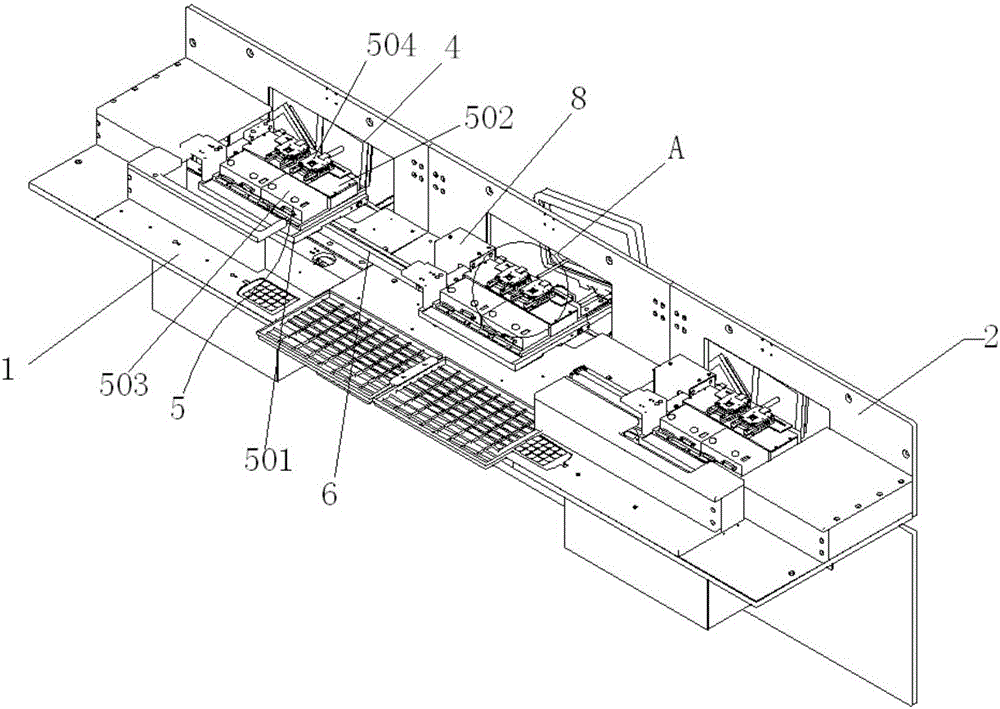

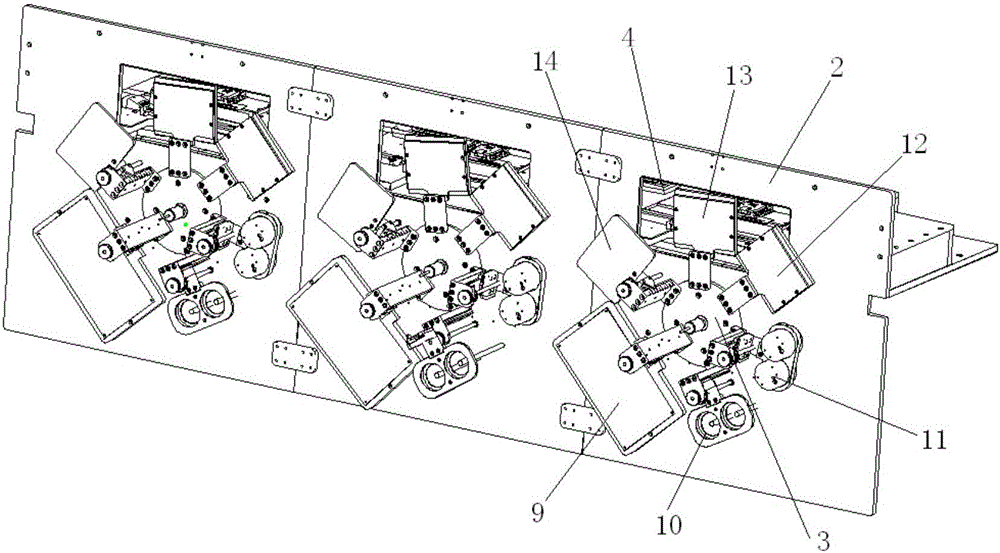

Integrated automatic assembly machine stand for double-camera module

ActiveCN105736538AImprove consistencyImprove performance in all aspectsMaterial gluingPretreated surfacesAdhesiveDisplay device

The invention discloses an integrated automatic assembly machine stand for a double-camera module. The integrated automatic assembly machine comprises three operating stations arranged on an operating platform; a primary camera fixing mechanism, an auxiliary camera fixing mechanism, a six-axis adjusting mechanism, a UV (ultraviolet) adhesive dispensing mechanism, an UV irradiating mechanism, an electric control mechanism and a display are provided by corresponding to each operating station, wherein the six-axis adjusting mechanism is used for carrying out six-axis adjustment on an auxiliary camera on the auxiliary camera fixing mechanism, such that the central axis of the auxiliary camera is parallel to the central axis of a primary camera; the UV adhesive dispensing mechanism is used for carrying out UV adhesive dispensing on the auxiliary camera subjected to six-axis adjustment; the UV irradiating mechanism is used for carrying out UV irradiating and curing on an adhesive-dispensed position; the electric control mechanism is used for controlling the six-axis adjusting mechanism, the UV adhesive dispensing mechanism and the UV irradiating mechanism to automatically work; the display is used for displaying whether the central axis of the primary camera is overlapped with the central axis of the auxiliary camera. According to the integrated automatic assembly machine stand disclosed by the invention, the integrated operation of three stations operated by one person is realized, such that the manpower and the hardware cost waste are saved efficiently, the production cycle of products is greatly shortened, and the uniformity and various performances of products are promoted.

Owner:KUNSHAN Q TECH CO LTD

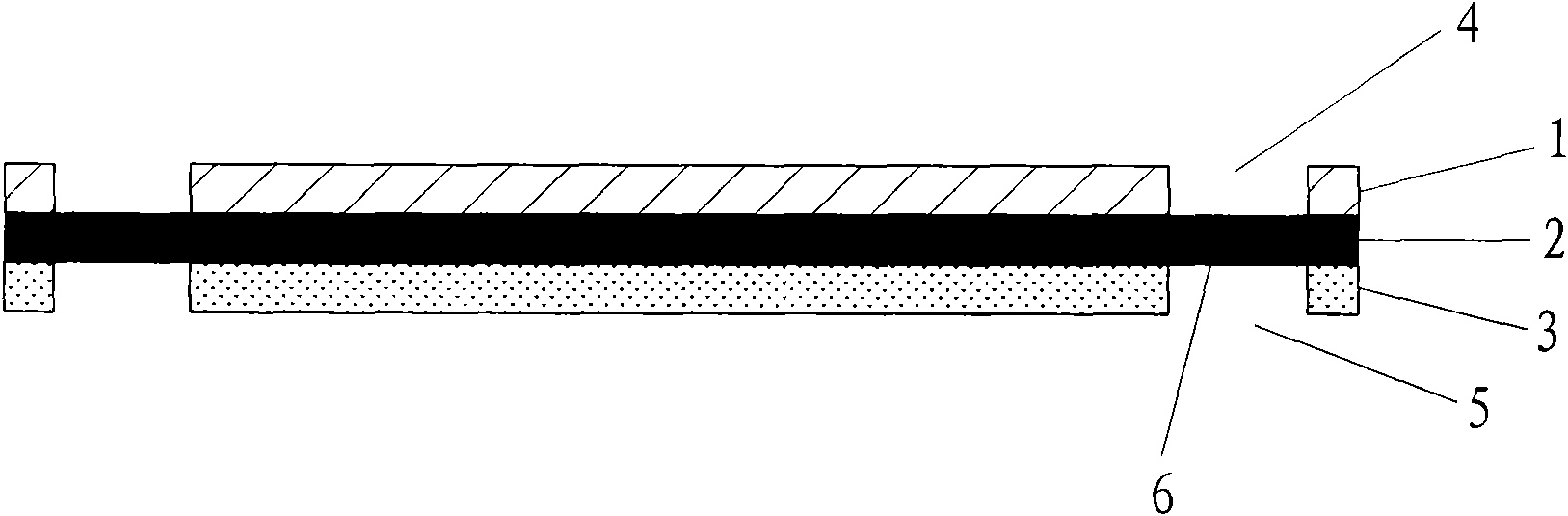

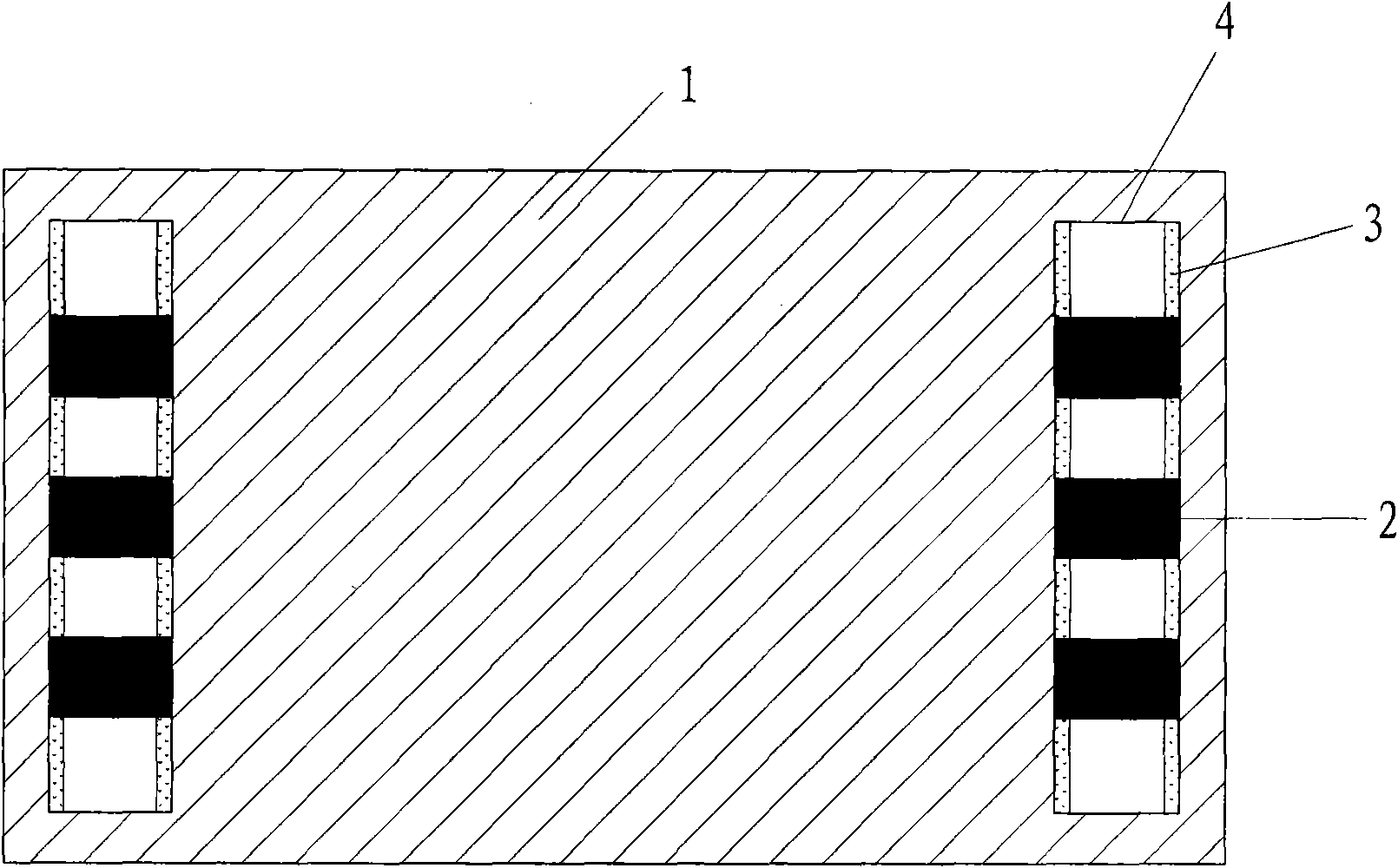

Single-side double contact flexible circuit board and making method thereof

ActiveCN101938883AEnhanced wrinkle and deformation resistanceImprove performancePrinted circuit detailsPrinted circuit manufactureFlexible circuitsLaser cutting

The invention discloses a single-side double contact flexible circuit board and a making method thereof. The single-side double contact flexible circuit board comprises a substrate layer, a copper foil layer and a covering film layer, wherein the substrate layer and the copper foil layer are both a single-side copper clad board. The making method comprises the following steps of: firstly, blanking, making a line on a copper foil surface of the single-side copper clad board, adhering a covering film with a drill hole and a punched opening on a covering film at the top layer, laminating and curing; secondly, laser-cutting an opening of a substrate at the bottom layer on the substrate surface of the single-side copper clad board with the made line, wherein the opening size of the substrate at the bottom layer is a little less than the size of a finger area of the covering film at the top layer; thirdly, removing a foreign body at a bare copper part of a product by adopting modes of plasma treatment and surface treatment; and fourthly, carrying out procedures of surface coating, character screen printing, electric measurement and punching forming to obtain the single-side double contact flexible circuit board, and therefore, the periphery of a golden finger is supported by the copper clad board substrate at the bottom layer, the buckling deformation resistance capacity of the golden finger in the production process and the subsequent use process is strengthened, the product making yield rate is enhanced, the cost waste is reduced, and the circuit board has the advantages of simple structure and good performance.

Owner:XIAMEN HONGXIN ELECTRON TECH

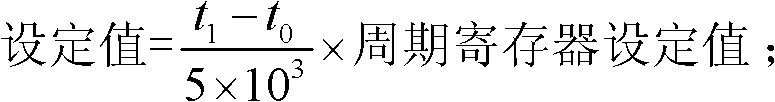

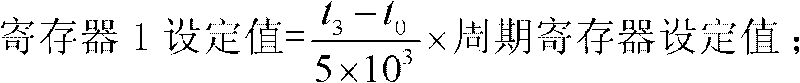

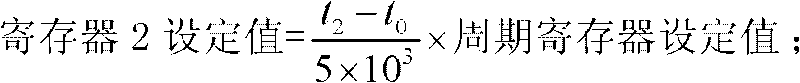

Method for restricting midpoint potential drifting of three-level inverter in direct drive wind power system

InactiveCN101764529ASimplified Modulation AlgorithmDrift suppressionWind energy generationDc-ac conversion without reversalMicrocontrollerThree level

The invention belongs to the control field of energy conversion devices of high capacity direct drive permanent magnet synchronous wind power systems, relating to a method for restricting the midpoint potential drifting of a three-level inverter. The method comprises the following steps of: determining the work mode of a three-level boost converter, calculating a critical inductance value, and determining a boosting inductance value; collecting a generator rotate speed signal of a direct drive wind power system and two capacitor voltage signals at direct current sides of the three-level boost converter; carrying out PI regulation according to a difference value between an actual rotate speed and a reference rotate speed by a microcontroller, and then outputting a reference value d* of the boosting ratio of the three-level boost converter; calculating a difference value between the two capacitor voltage signals at the direct current sides, carrying out PI regulation of the other path on a difference value between the difference value and zero, and outputting a difference reference value theta * between switching signals; and calculating respective conducting and shutting time of two switching devices, and controlling the on / off of the two switching devices. The invention can effectively restrict the midpoint potential drifting at the direct current sides of the three-level inverter on the premise of not increasing circuits for regulating the midpoint potential.

Owner:TIANJIN UNIV

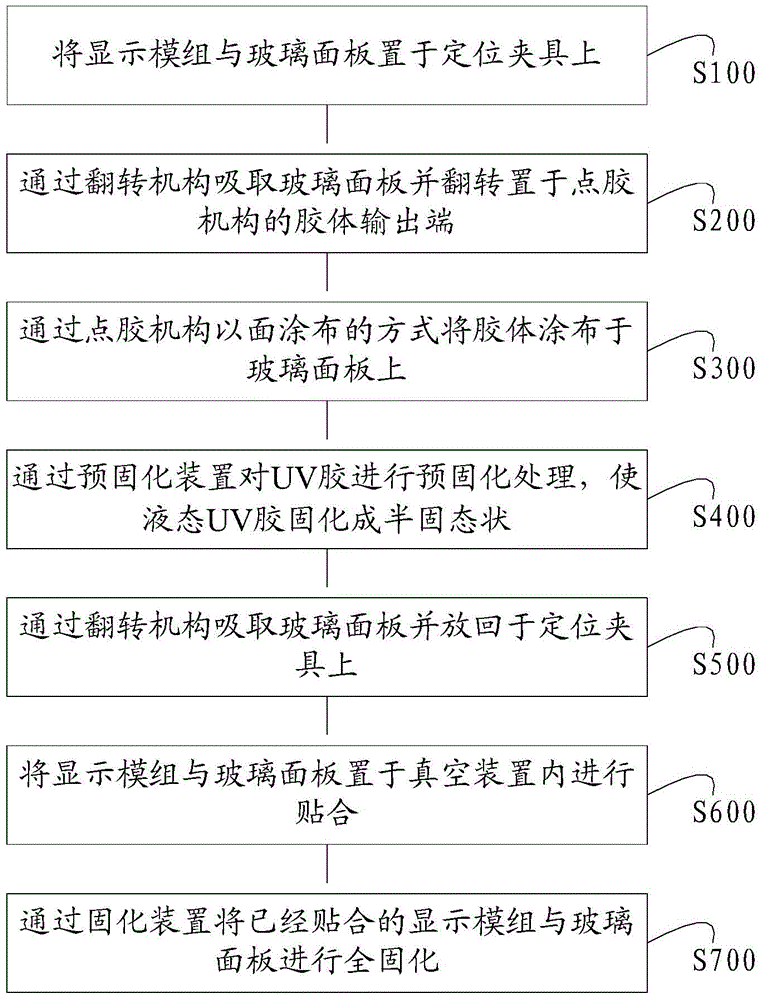

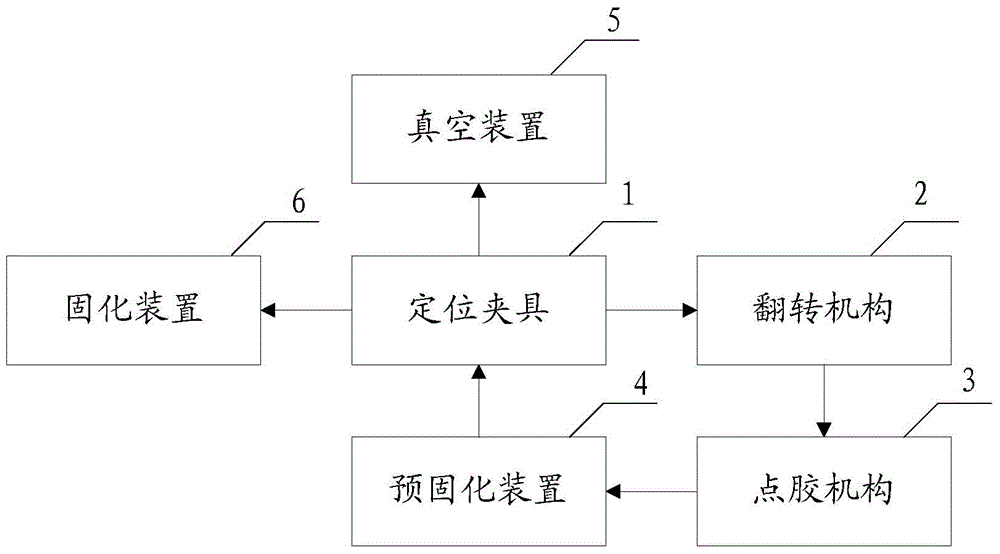

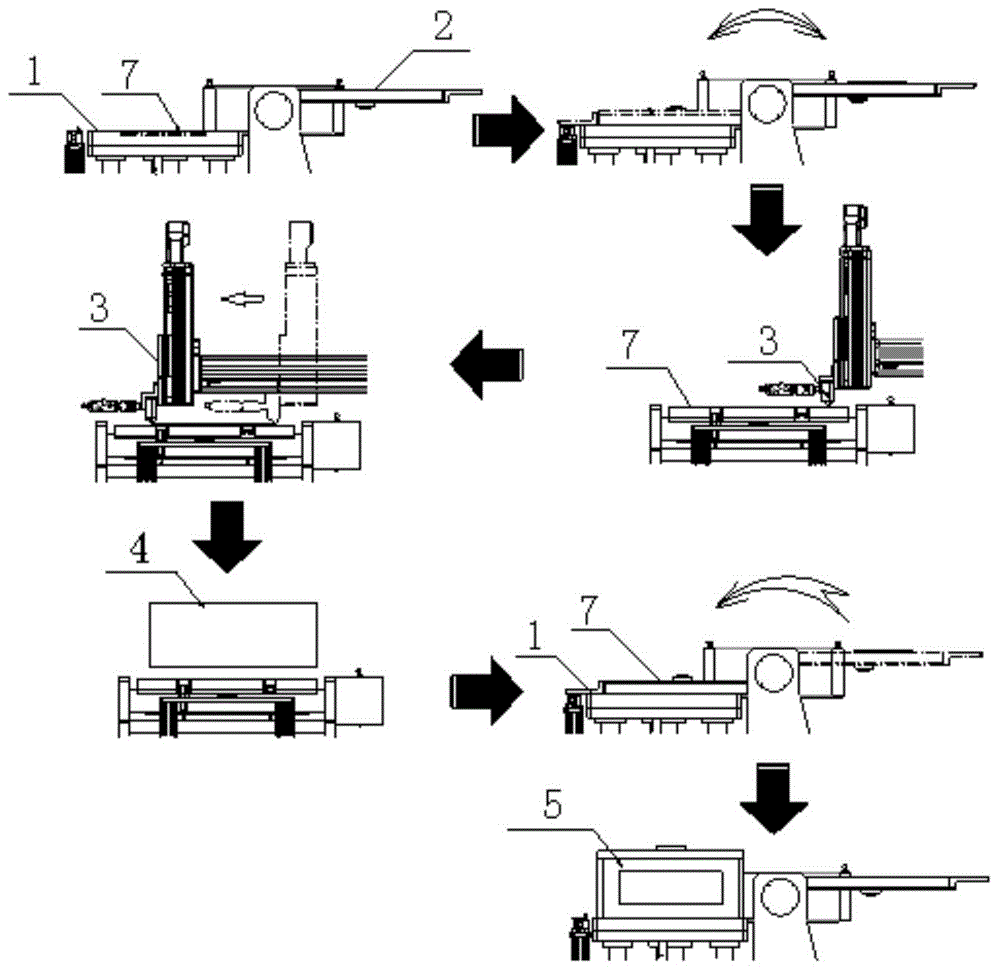

Screen laminating method and system

InactiveCN104571663AReduce cost wasteAvoid glue overflowLamination ancillary operationsLaminationAdhesiveEngineering

The invention belongs to the technical field of screen lamination, and particularly relates to a screen laminating method and system. The screen laminating method comprises the following steps: a, placing a display module and a glass panel on a positioning fixture; b, sucking the glass panel through an overturning mechanism and reversely placing the glass panel at the adhesive output end of an adhesive dispensing mechanism, wherein the adhesive dispensing mechanism is a linear adhesive dispensing valve; c, coating an adhesive on the glass panel in a surface coating way through the adhesive dispensing mechanism; d, sucking the glass panel through the overturning mechanism, placing the glass panel back onto the positioning fixture, and laminating the glass panel with the display module. Adhesive coating is performed through the surface coating way, so that the steps of adhesive scattering or levelling and the like in the existing pinhole type adhesive coating way are omitted, the operation time is saved, and the yield is increased; a UV (Ultraviolet) adhesive is pre-cured, so that the phenomena of adhesive leakage, the adhesive absence, edge unevenness and the like occurring in the laminating process of a liquid UV adhesive are avoided.

Owner:SHENZHEN TENSUN IND EQUIP

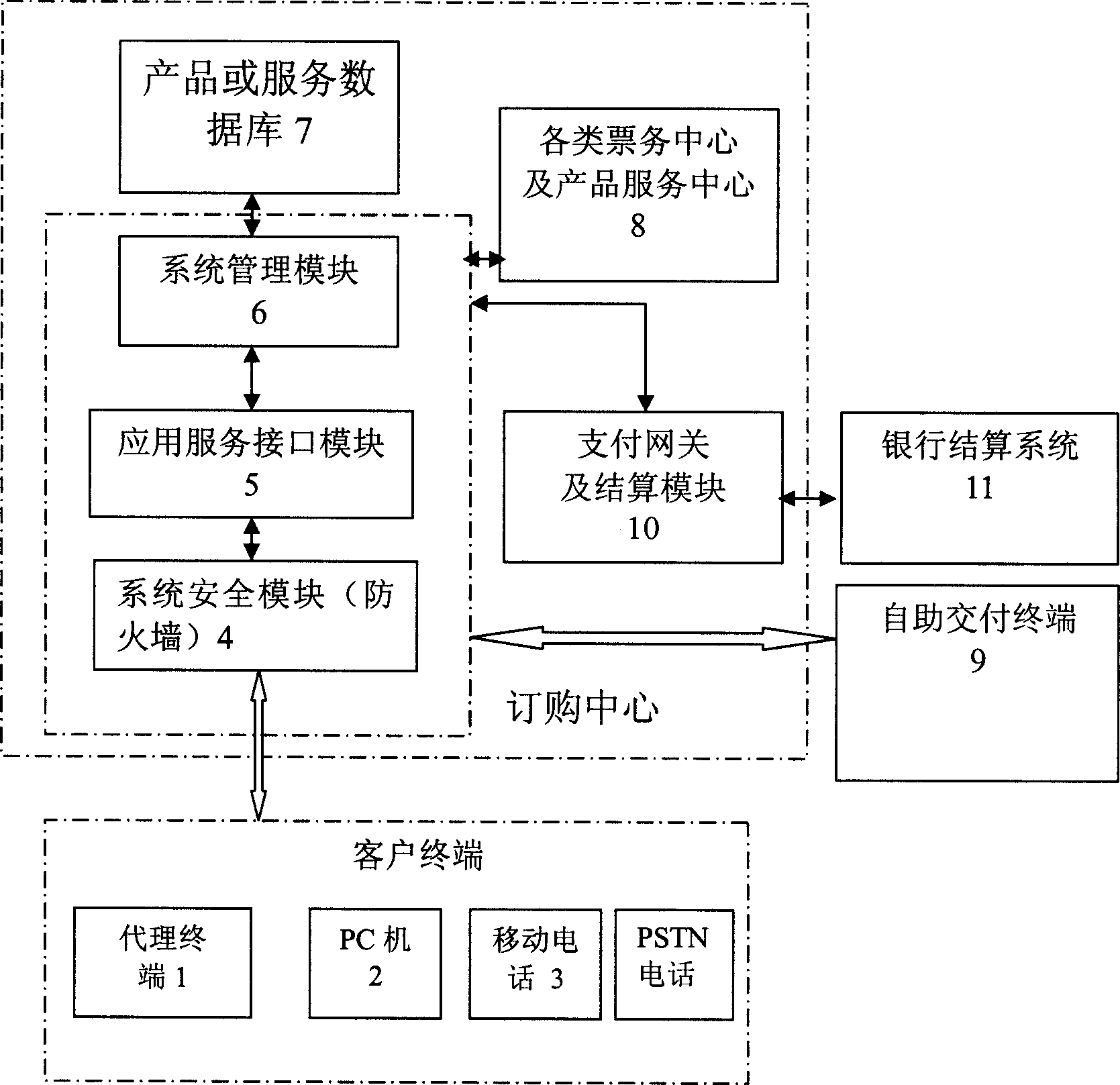

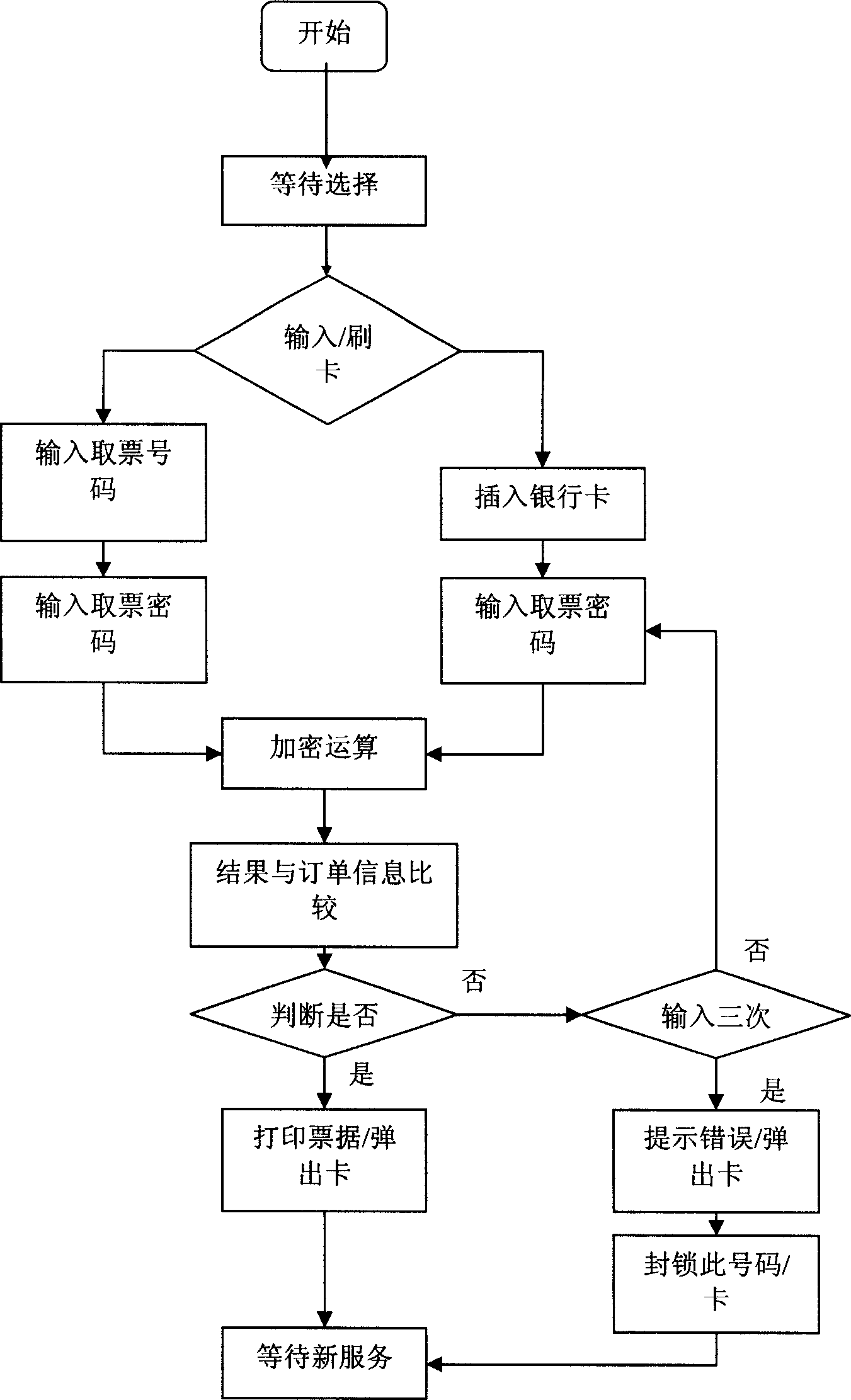

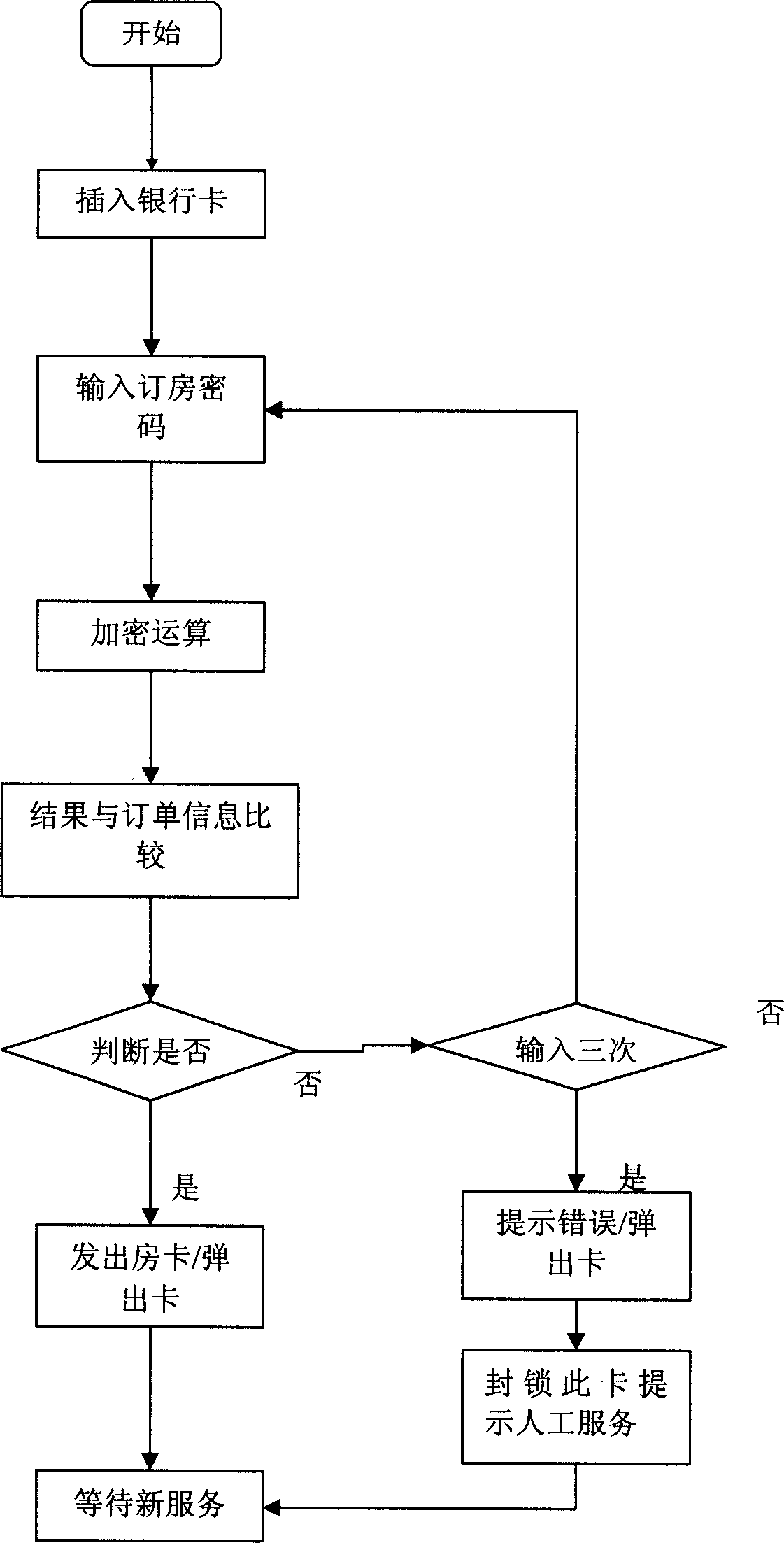

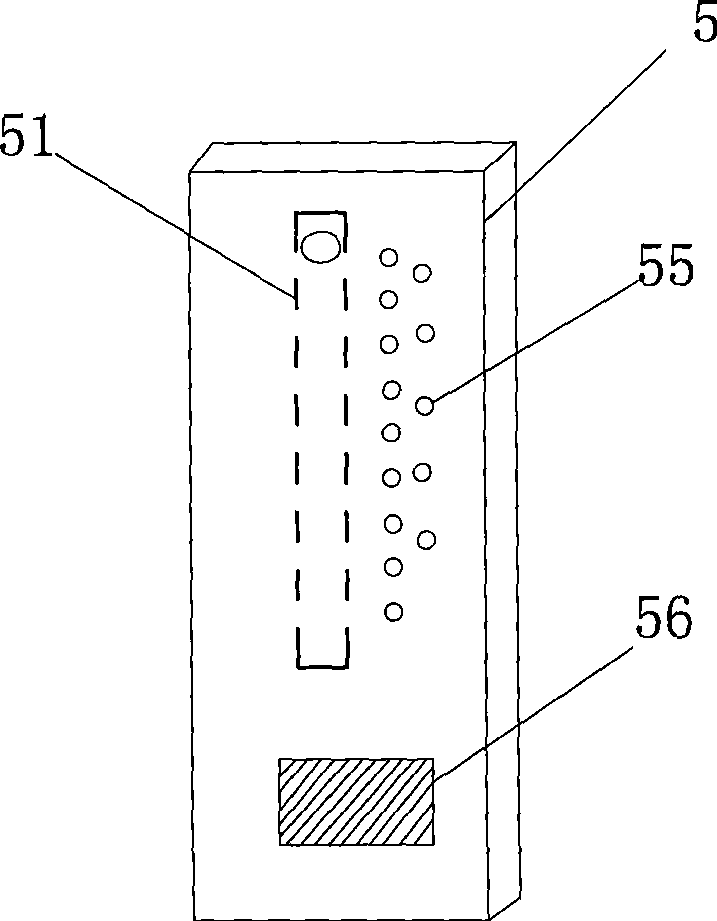

Network self-helf service system and its purchase-delivery method

InactiveCN1744124AReduce transaction costsLow costPayment architectureCommerceProduct orderComputer terminal

The system includes an ordering center, self-help delivery terminal, user terminals, balancing system of bank, and self-help service center. User terminals and balancing system of bank are connected to the ordering center respectively. Collecting ordering information input by users as well as authentication information of ID, user terminals up loads the collected information to the ordering center and receives information returned back from the ordering center. Collecting authentication information of ID input from user, self-help delivery terminal outputs product ordered by user after the ordering center authenticates ID of user. Information of transaction provided by the system is transparent. Procedure of transaction does not need salesperson to participate in. the invention lowers cost for selling and delivering tickets. User can obtain automatic, quick and convenient service from self-help delivery terminal.

Owner:蔡军

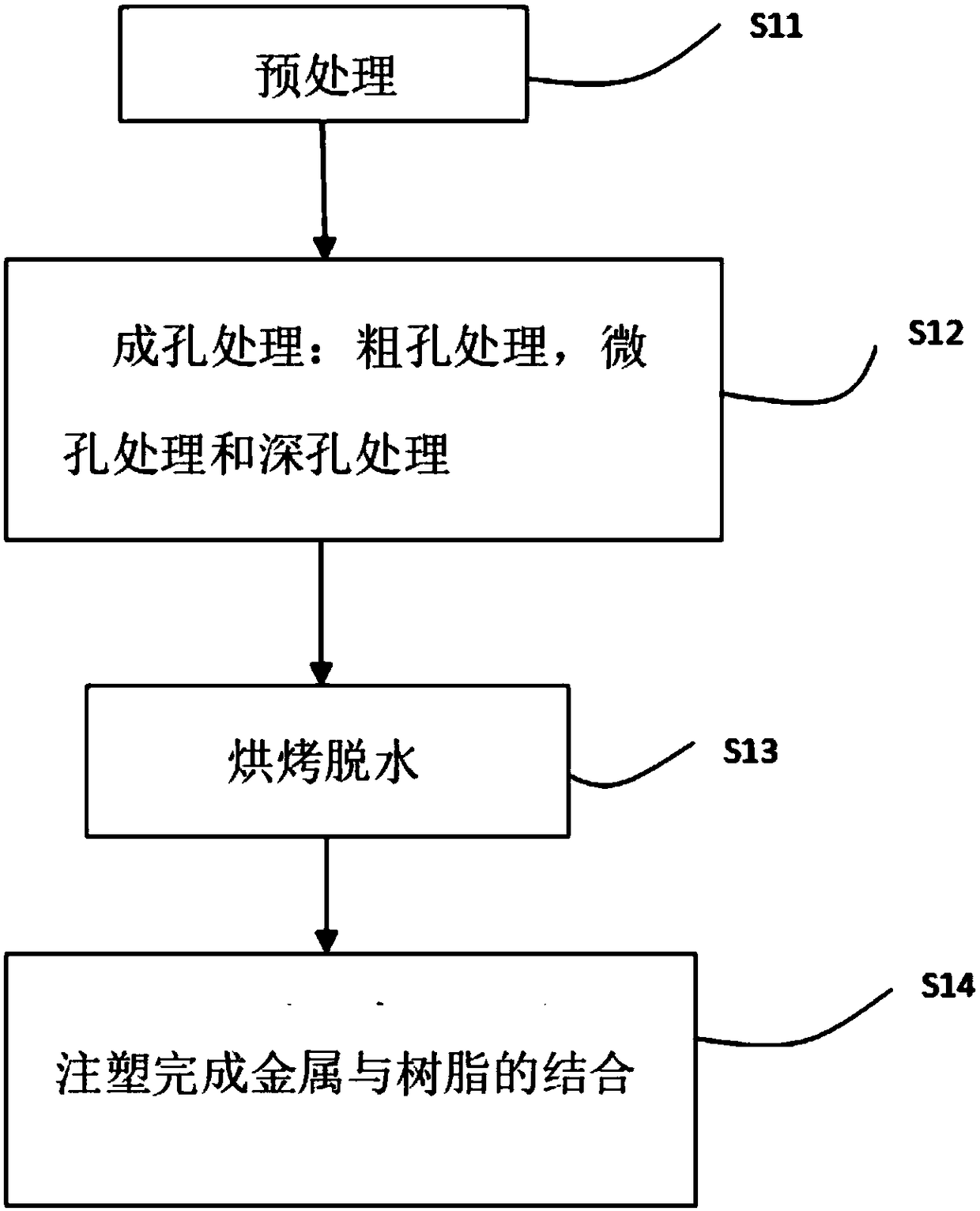

Method for combining metal with resin

The invention discloses a method for combining metal with resin. The metal is subjected to coarse hole processing to form a micropore of which the diameter range is 10-30nm and the depth is 0.2-2 micrometers, and then, the metal is subjected to deep hole processing to form a nanometer hole of which the aperture range is 40-100nm and the hole depth is 2-5 micrometers; after hole forming processing,an etching hole, the micropore and the nanometer hole coexist, and the combination of the metal and the resin is finished through injection on the formed nanometer hole. Injection molding is carriedout through the processed nanometer hole, so that the metal and the plastic cement are in direct hook face combination, and a clamping hook groove does not need to be additionally arranged on the metal for holding adhesive. The combination strength of the method is superior to strength necessary for subsequent machining, the flexibility of a production plan can be improved, a subsequent manufacture procedure reject ratio is reduced, production efficiency is greatly improved, and cost waste is lowered.

Owner:广州凯腾新材料科技有限公司

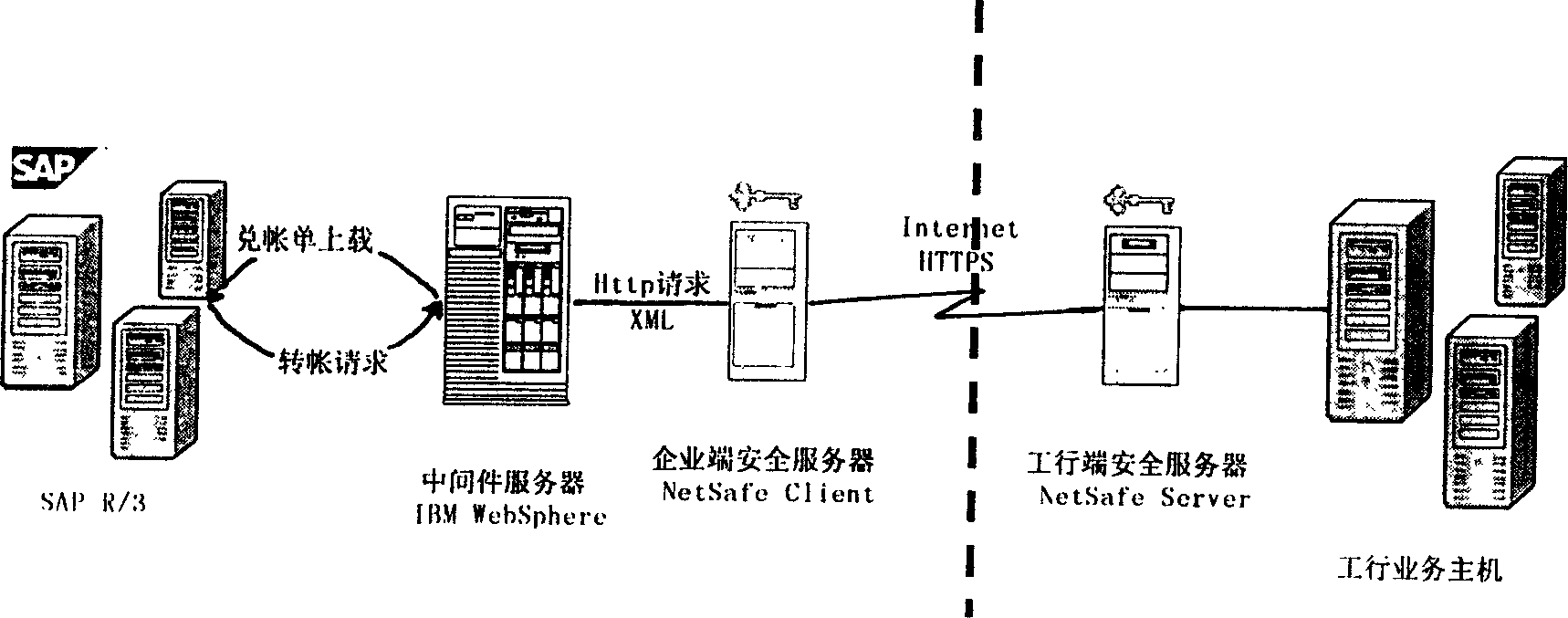

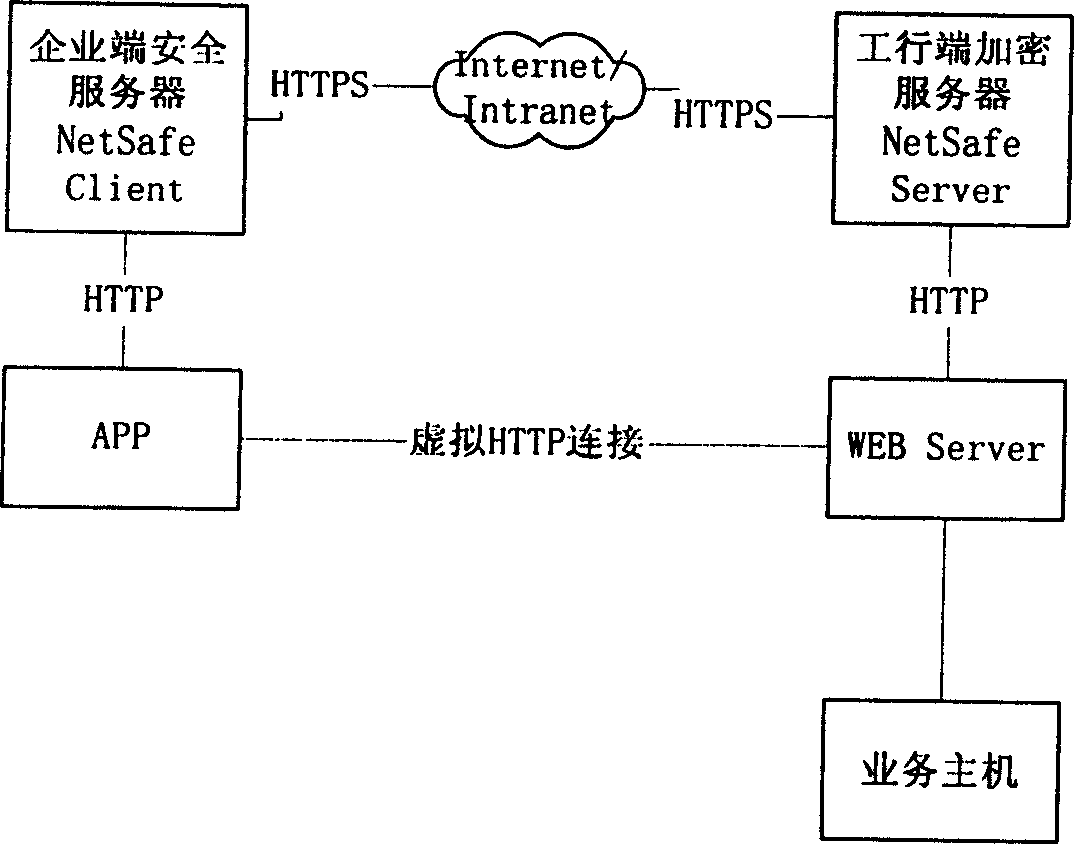

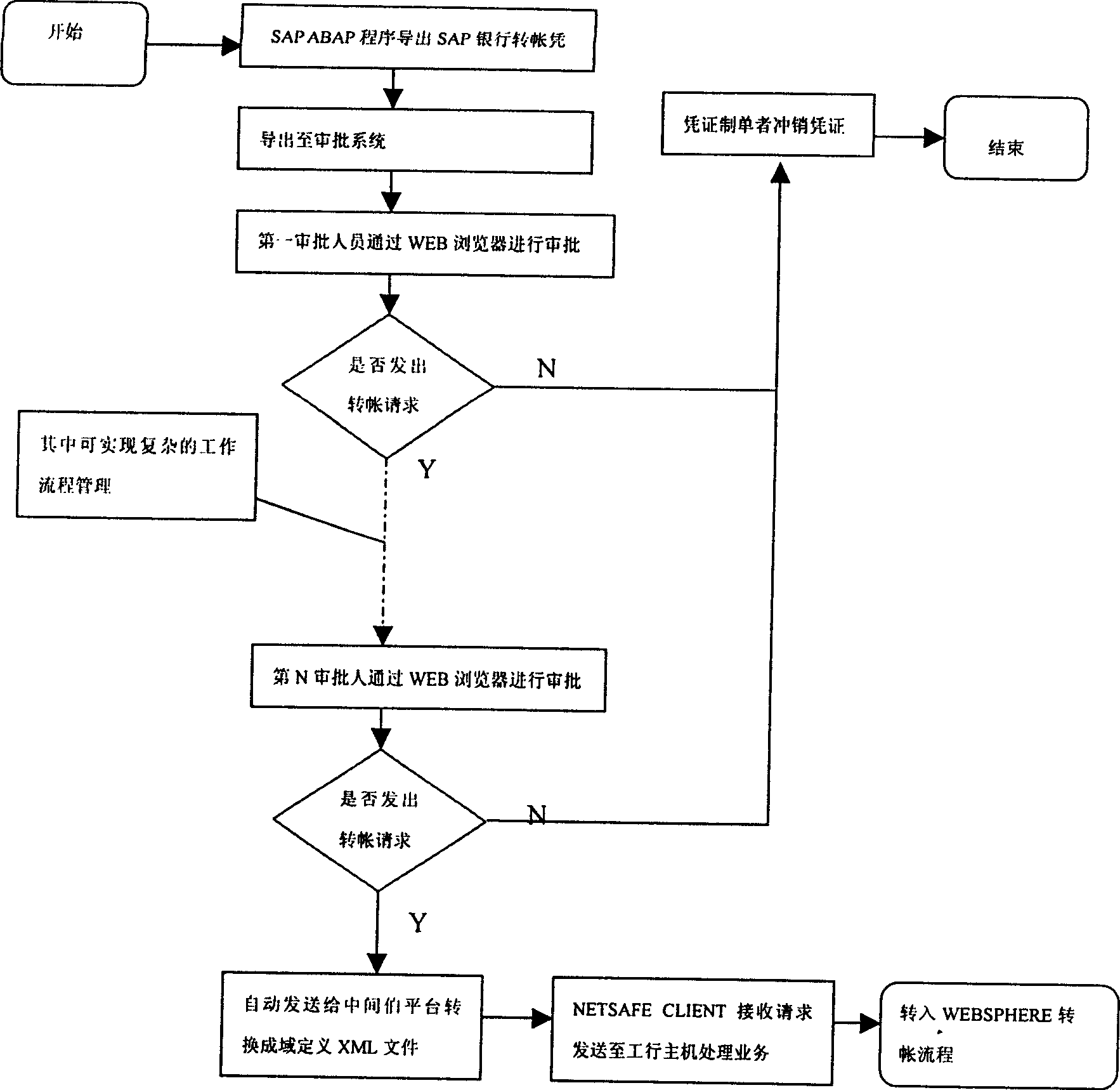

Network bank trade system and method between enterprise and bank

InactiveCN1598841AEnsure safetyWill not be tampered withData switching networksSpecial data processing applicationsPaymentBusiness Personnel

The invention relates to a method of network bank trading between companies and banks. The system includes computer units in bank and company, thereinto, SAP software system is used in company for every finance personnel. Payment service credence is programmed in each client by finance personnel. The payment data is uploaded to company server by special person using eduction program through examination of relative service personnel. Payment check personnel approve payment information through WEB browser in client according to respective rights. Company payment information after approval interacts with bank service host through Internet. In charge of security server in company and bank, trade request is sent to encryption server after encryption and is sent to background to process server after unencrypted by server in bank. At last, the result is returned.

Owner:SINOPEC YANGZI PETROCHEM

Aluminum profile surface spraying device and operation method thereof

ActiveCN111905954AFull sprayImprove spraying efficiencyPretreated surfacesCoatingsAssembly lineMaterials science

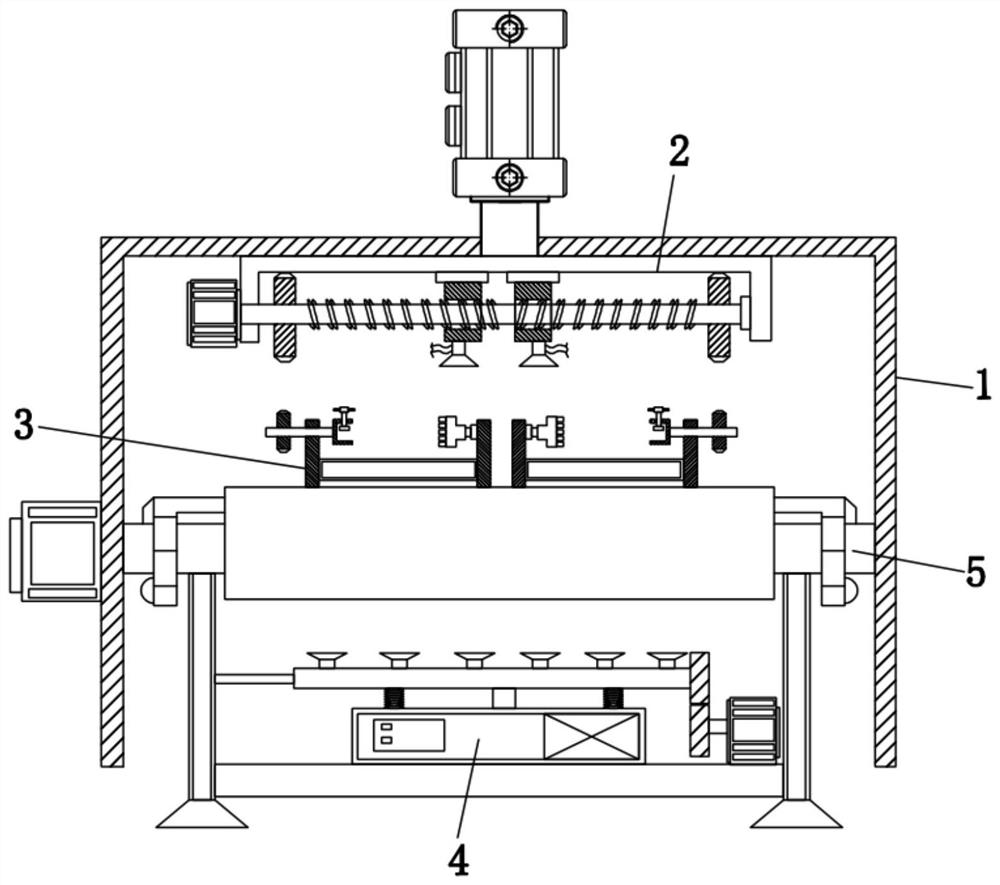

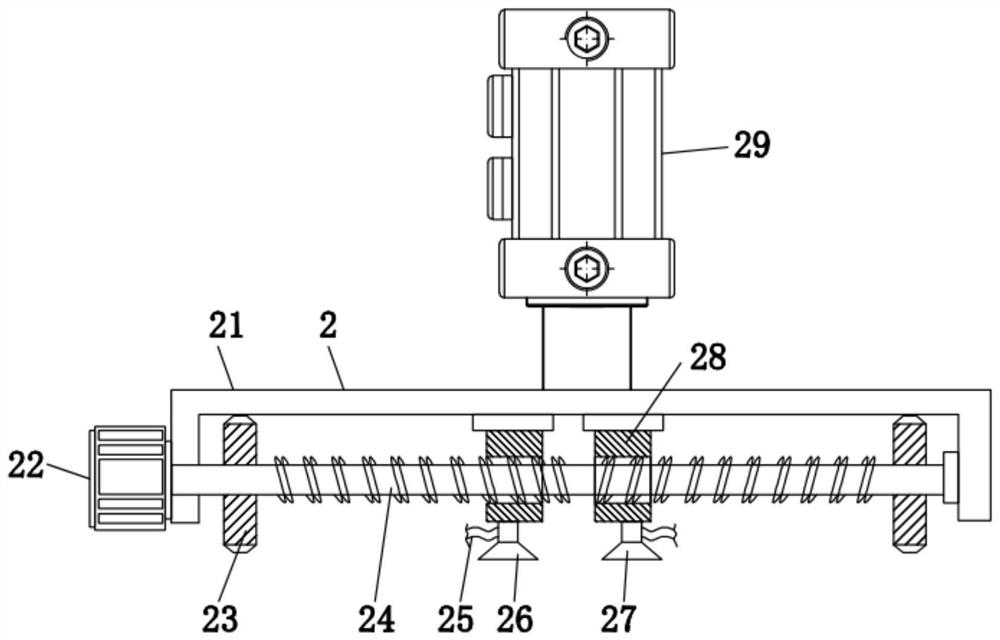

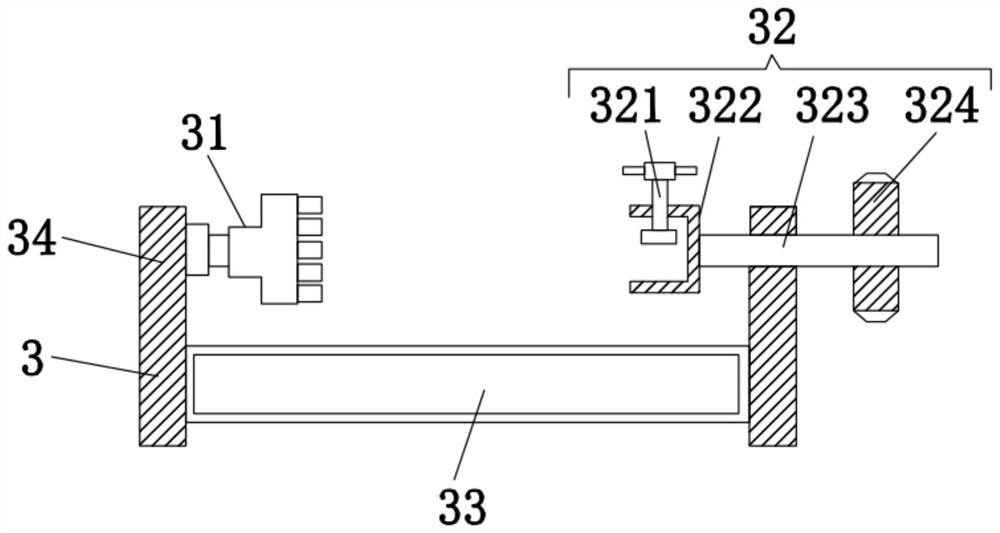

The invention discloses an aluminum profile surface spraying device and an operation method thereof. The aluminum profile surface spraying device comprises a shell, a spraying mechanism is assembled at the top end of an inner cavity of the shell, a conveying belt is assembled in the inner cavity of the shell, the conveying belt is located at the lower end of the spraying mechanism, a plurality ofclamping mechanisms are assembled at the top end of the conveying belt, and a drying mechanism is assembled at the bottom end of the inner side of the conveying belt. Through cooperation of the clamping mechanisms and the spraying mechanism, aluminum profiles can be turned over and sprayed at the same time, thereby being comprehensively sprayed, continuous conveying is conducted through the conveying belt, assembly line type conveying and spraying processing can be completed, and therefore the spraying efficiency and the spraying quality of the aluminum profiles are improved. The sprayed aluminum profiles can be dried through the drying mechanism, the aluminum profiles do not need to be transferred again, influence on the overall flatness of the paint surfaces is avoided, the spraying quality of the aluminum profiles is effectively guaranteed, and cost waste caused by rework is reduced.

Owner:江西福德铝业有限公司

Airbag type inner framework form traveler and primary tunnel supporting shotcrete construction method

ActiveCN105507927ASimple structureEasy to processMining devicesUnderground chambersShotcreteArchitectural engineering

The invention discloses an airbag type inner framework from traveler and a primary tunnel supporting shotcrete construction method. The form traveler comprises a movable supporting framed bent, an inflatable formwork located on the outer side of the movable supporting framed bent, and a retractable supporting device for supporting the inflatable formwork, and the retractable supporting device is installed on the movable supporting framed bent and located on the inner side of the inflatable formwork. The construction method includes the steps: firstly, forwarding the airbag type inner framework from traveler in place; secondly, performing primary tunnel supporting shotcrete construction; thirdly, performing primary tunnel supporting shotcrete construction on a next tunnel section; fourthly, repeating the third step for multiple times till the primary tunnel supporting shotcrete construction process of all the tunnel sections is finished. The airbag type inner framework from traveler is reasonable in design, simple to construct and good in using effect, resilience rate of primary tunnel supporting shotcrete is effectively controlled through an airbag type inner framework, construction efficiency is high, construction period is short, construction quality is high, and zero resilience rate of primary tunnel supporting shotcrete can be realized.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

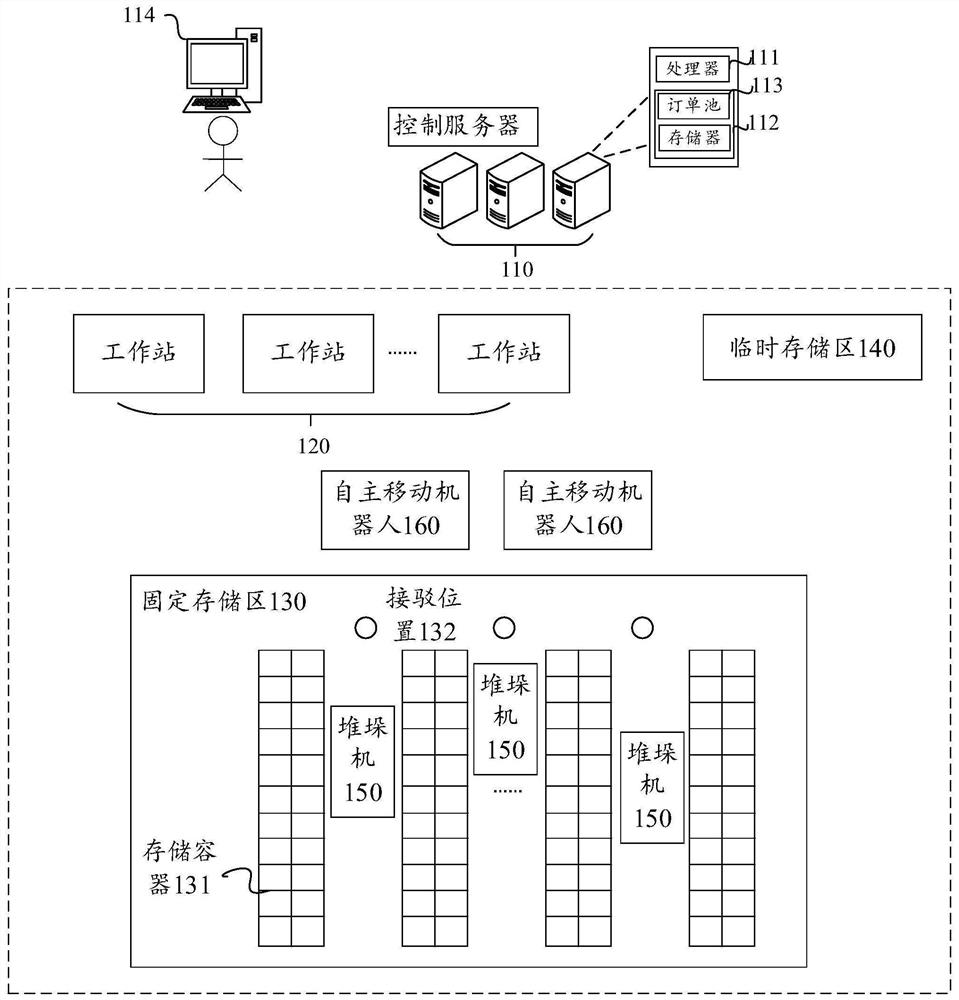

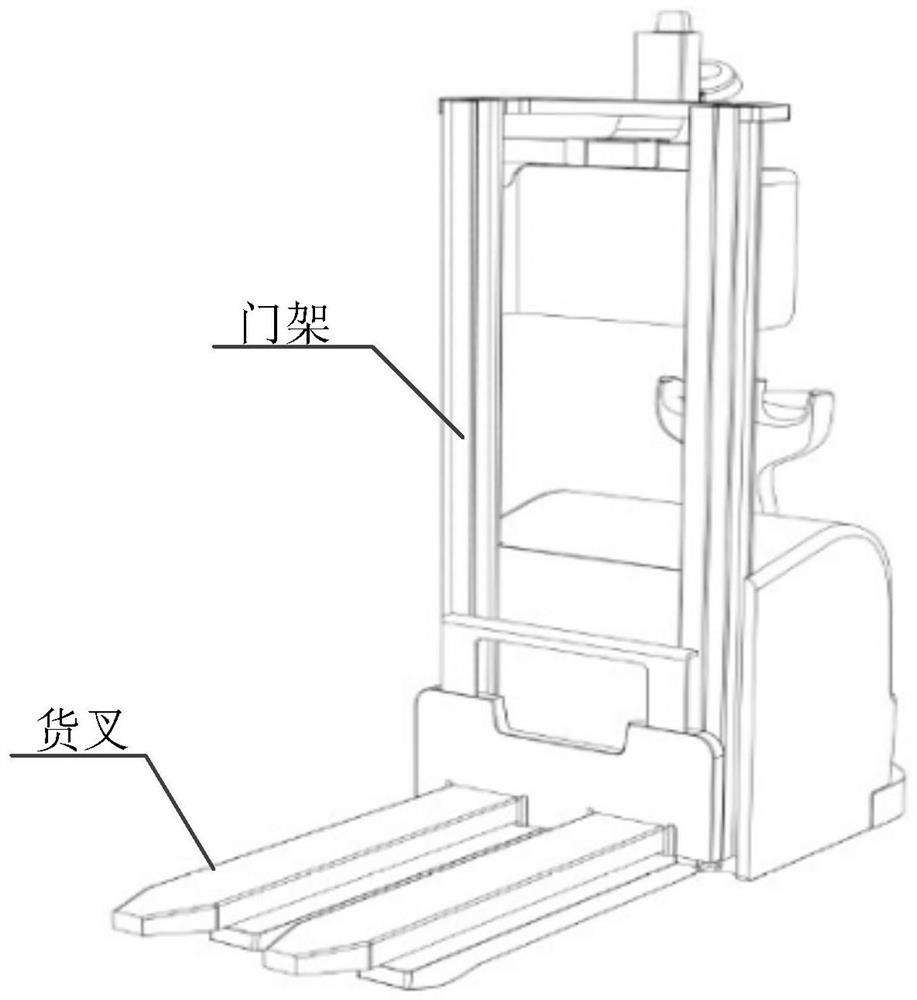

Warehouse management system and method

ActiveCN112224733AImprove efficiencyFlexible to meet elastic needsLogisticsTotal factory controlStack machineMachine

The invention provides a warehouse management system and method. The system comprises a control server, autonomous mobile robots, workstations, a temporary storage region, and stacking machines, wherein the stacking machines and the autonomous mobile robots are in communication connection with the control server. The control server is configured to determine a target storage container hit by a first order, a storage position of the target storage container, a target connection position, the target workstation and a target temporary storage area according to the first order, send a container taking-out instruction to the target stacking machine and send a container carrying instruction to the target autonomous mobile robot. The target stacking machine is configured to take out the target storage container from the storage position and carry the target storage container to the target connection position in response to the container taking-out instruction. The target autonomous mobile robot is configured to respond to the container carrying instruction and carry the target storage container from the target connection position to the target workstation to complete at least one of a sorting task of orders and caching of the target temporary storage area.

Owner:BEIJING JIZHIJIA TECH CO LTD

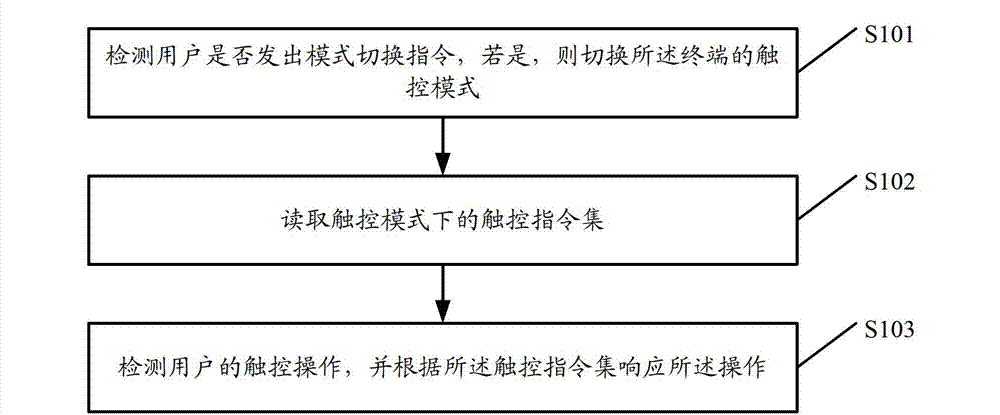

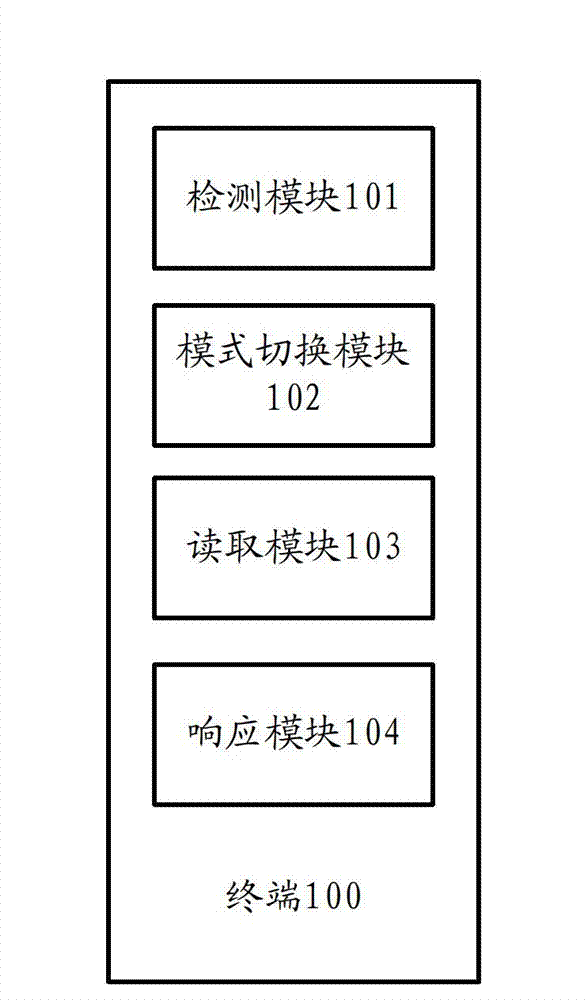

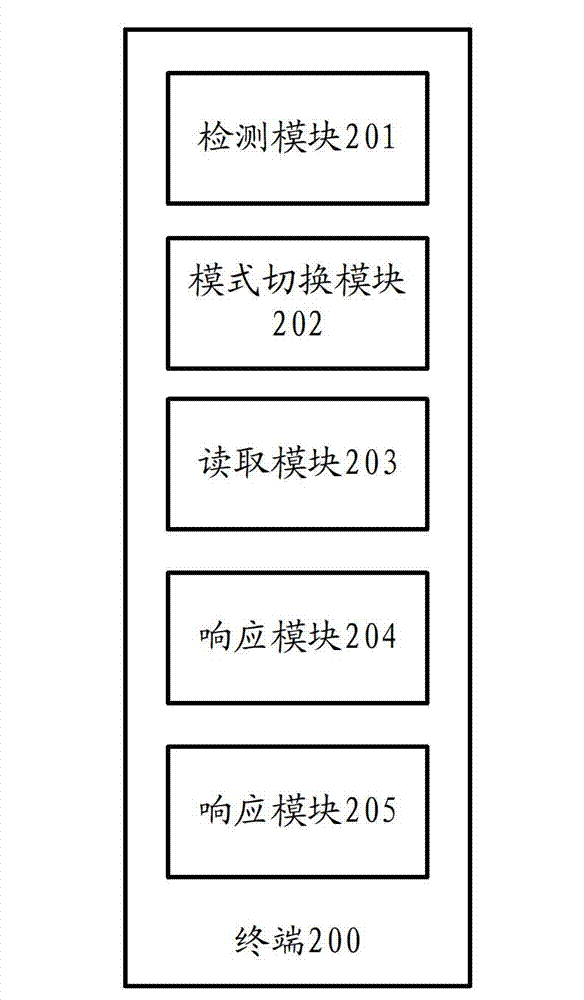

Terminal control method and terminal

InactiveCN103034443AHumanizedImprove intelligenceInput/output processes for data processingHuman–computer interactionMode switch

The embodiment of the invention discloses a terminal control method and a terminal. The method comprises the following steps of: detecting whether the user operation sends a mode switching instruction or not, if so, switching the touch mode of the terminal; reading a touch instruction set in the touch mode; and detecting the touch operation of a user, and responding to the operation according to the touch instruction set. Through the touch mode of the expansion terminal, the recognizable screen sliding gesture of the terminal is added, so that the function instructions defined by the terminal are various, the user experience is enhanced, and the terminal has the characteristic of humanity, and thus the intelligence of the terminal is improved.

Owner:DONGGUAN YULONG COMM TECH +1

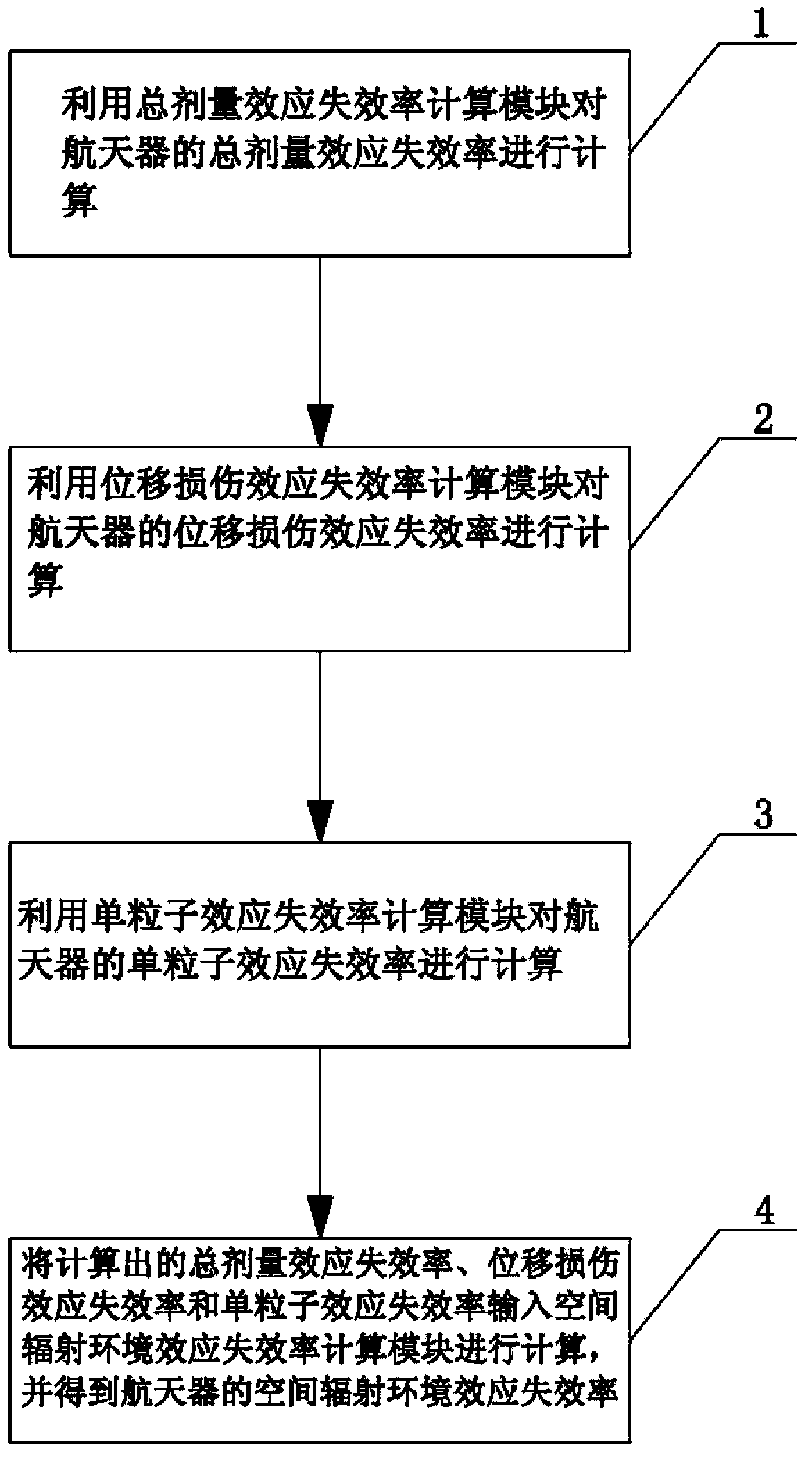

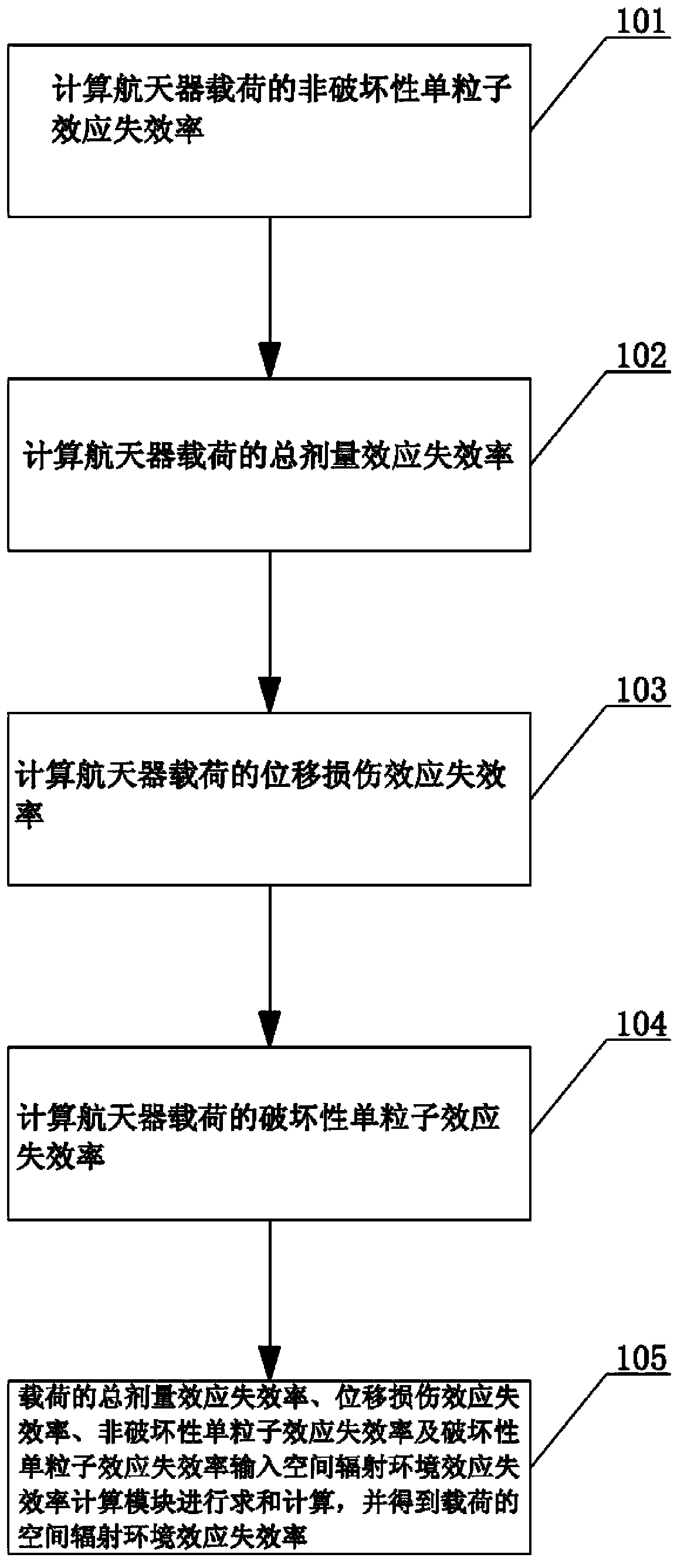

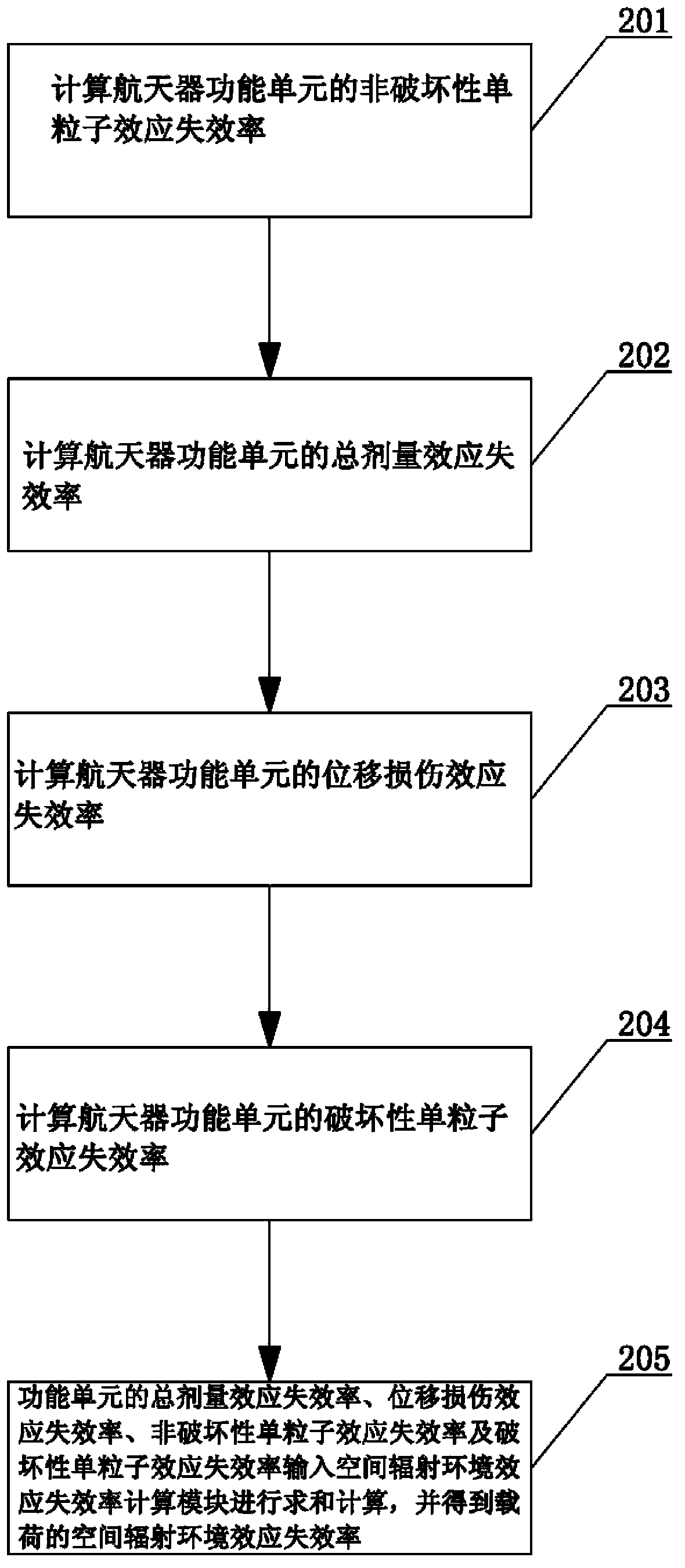

Method for designing reliability index of space radiation environment

ActiveCN104142628AControl reliabilityControl failure riskSimulator controlFailure rateEnvironment effect

The invention relates to a method for designing the reliability index of a space radiation environment, in particular to a method for designing the space radiation environment effect failure rate of a spacecraft to improve the reliability of the spacecraft. The method comprises the steps that a total dose effect failure rate calculation module is used for calculating the total dose effect failure efficiency of the spacecraft; a displacement damage effect failure rate calculation module is used for calculating the displacement damage effect failure rate of the spacecraft; a single-particle effect failure rate calculation module is used for calculating the single-particle effect failure rate of the spacecraft; the calculated total dose effect failure rate, the displacement damage effect failure rate and the single-particle effect failure rate are input into a space radiation environment effect failure rate calculation module to be calculated, and the space radiation environment effect failure rate of the spacecraft is obtained. According to the method for designing the reliability index of the space radiation environment, the reliability analysis and optimization design guidance of an electronic system of the spacecraft can be facilitated, and the design and implementation cost of aerospace engineering is further lowered.

Owner:BEIJING SHENGTAOPING TEST ENG TECH RES INST

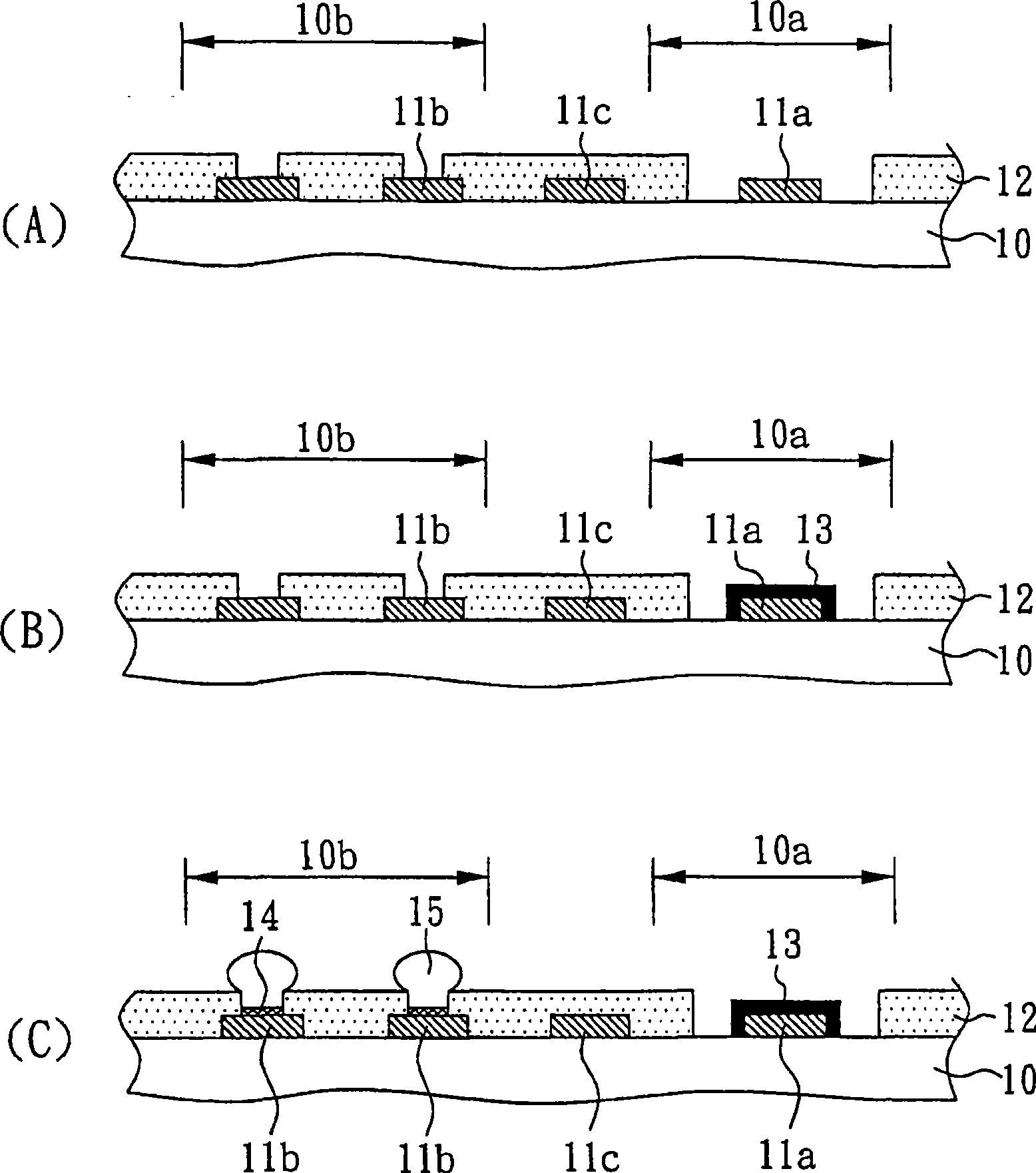

Semiconductor package substrate and fabrication method thereof

ActiveCN101383335AMaintain electrical qualityLow costSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention relates to a semiconductor packaging substrate and a fabricating method thereof. The invention is characterized in that electric connection pads on the surface of a circuit board provided with a wire bonding area and a lug area synchronously form a nickel / palladium / metal layer, so as to reduce the flow of process and the waste of time. The effect for enhancing the binding force between the substrate and the chip exists in the nickel / palladium / metal layer.

Owner:PHOENIX PRECISION TECH CORP

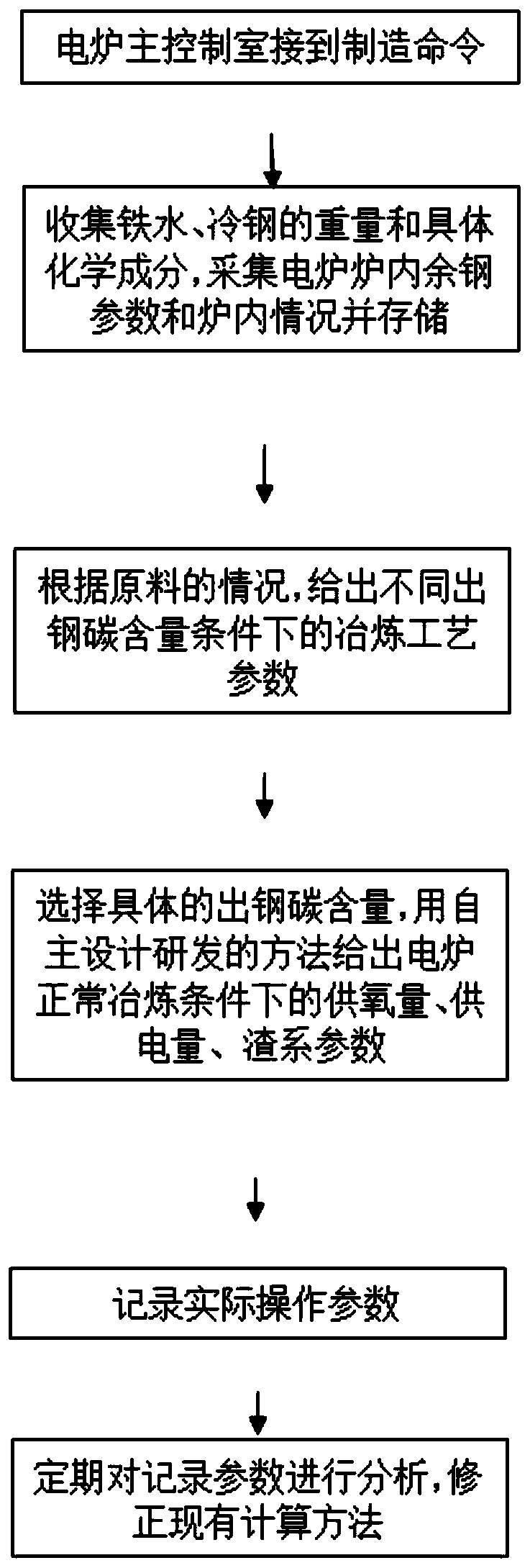

Prediction system and prediction method for tapping carbon component of 100t direct-current electric arc furnace

ActiveCN110322057ASimple processImprove quality controlSteel manufacturing process aspectsForecastingDc arc furnaceData acquisition

The invention relates to a prediction system and a prediction method for tapping carbon components of a 100t direct-current electric arc furnace. The prediction system comprises a data acquisition module, a data storage module, a data analysis module and an operation guidance module, the prediction method comprises the following steps: the data acquisition module acquires main raw material data offurnace smelting; the data storage module is used for storing the acquired data and establishing a database; the data analysis module performs analysis and comparison according to the data provided by the database, and proposes oxygen supply and power supply parameters under different tapping carbon content conditions; and the operation guidance module gives an oxygen supply intensity value and apower supply operation curve according to the data provided by the analysis module and in combination with operation rules and tapping carbon requirements. According to the method, a large amount ofdata is collected in the field production process, database resources are used for supporting accurate logic analysis and judgment, and operation process parameters for different tapping carbon components are deduced according to specific steel grade carbon component requirements.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

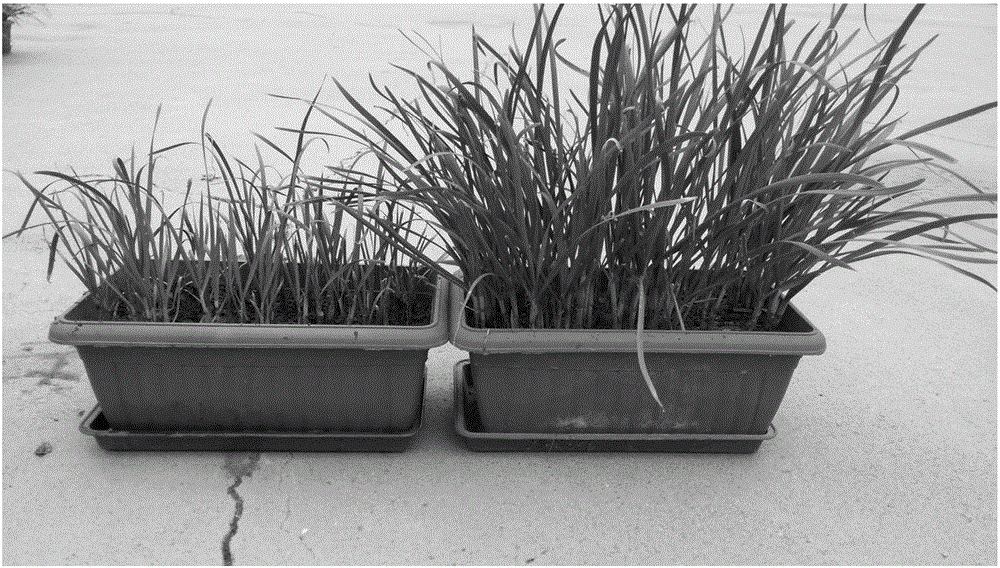

Pot-plant leek culture matrix and culture method thereof

InactiveCN106478184AFull of nutritionPromote growthCultivating equipmentsPlant protectionDisease damageOrganic fertilizer

The invention discloses a pot-plant leek culture matrix and a culture method thereof. The pot-plant leek culture matrix is composed of, by weight, 2 parts of rural frozen earth, 1 part of decomposed manure, 1 part of bio-organic fertilizer, 2 parts of turf soil, 1 part of vermiculite, 2 parts of plant ash and 1 part of castor leaves; the organic content in the bio-organic fertilizer is greater than 70%, the number of content of beneficial bacteria is not less than 2X10<9> / g, N-P2O5-K2O=2-3-5, and the total content is greater than 10%. The adopted culture matrix formula is the optimum formula acquired by an applicant via multiple tests, the culture matrix is reasonable in formula, fewer in pest and disease damage, high in leek yield and good in quality; with the method, quality of leek is improved by adopting various comprehensive measures which are top choices targeting at the leek, the yield of the leek is guaranteed, and meanwhile, occurrence of pest and disease damage is reduced.

Owner:LUDONG UNIVERSITY +2

Cleaning device for mechanical part

InactiveCN108311448AEasy to washEasy to cleanDrying gas arrangementsCleaning using toolsEngineeringMechanical engineering

The invention discloses a cleaning device for a mechanical part. The cleaning device comprises a bottom plate, supporting column bodies A are symmetrically fixed to the top surface of the bottom plate; a water tank is arranged on the top surfaces of the supporting column bodies A, the top surface of the water tank is welded with a cone cylinder A which is integrally formed with the water tank, anda sleeve A which is integrally formed with the cone cylinder A is welded and fixed on the top surface of the cone cylinder A; a cone cylinder B is arranged in the cone cylinder A, and multiple squarethrough holes A are uniformly formed in the side surface of the cone cylinder B; a sleeve B is arranged in the sleeve A, multiple square through holes B are uniformly formed in the side surface of the sleeve B; and the conical cylinder A is fixedly connected to the bottom surface of the conical cylinder B through an annular plate A. According to the cleaning device, the part can be cleaned from all directions, the surface of the part is washed more uniformly and thoroughly, and the multiple parts can be washed at one step, the cleaning efficiency is high, a proper amount of flushing can be performed according to the dirt accumulation degree of the part, so that the good cleaning effect is achieved; and meanwhile, the probability that the part is rusted, damaged or stained again in the transportation process is reduced, and the cleaning device is high in use efficiency and is very practical and reliable.

Owner:DONGGUAN KAILEDI NUMERICAL CONTROL SCI & TECH CO LTD

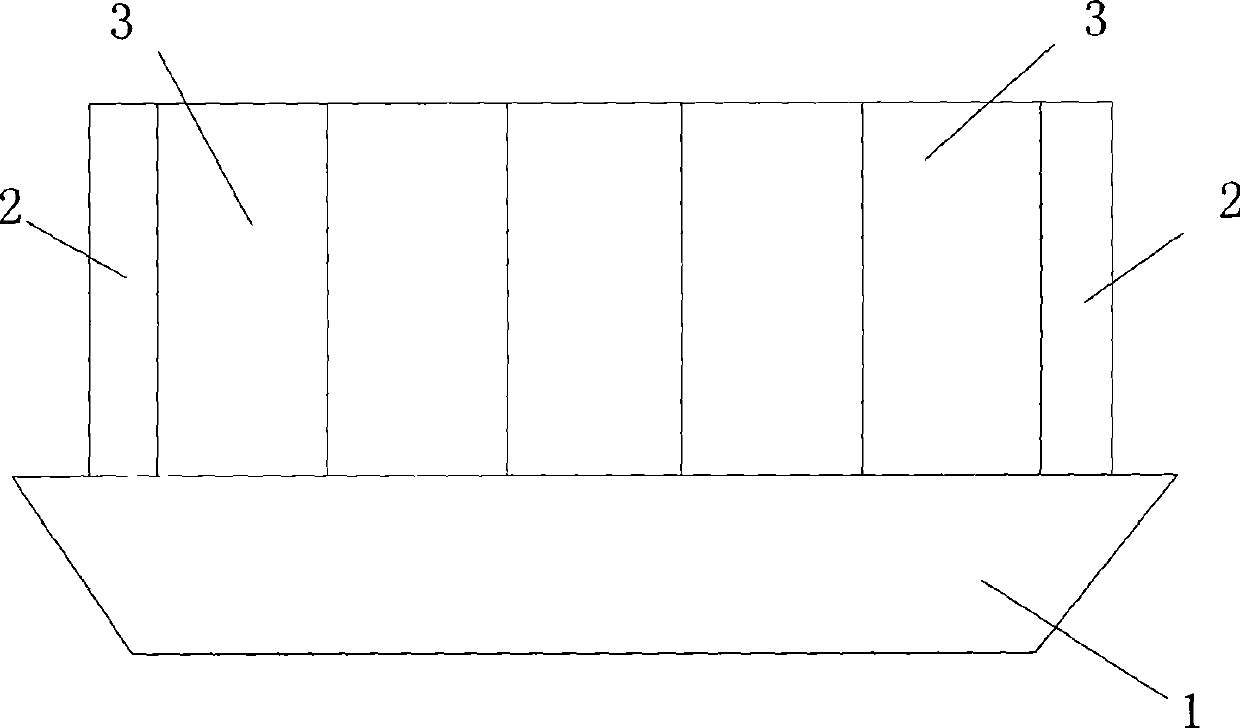

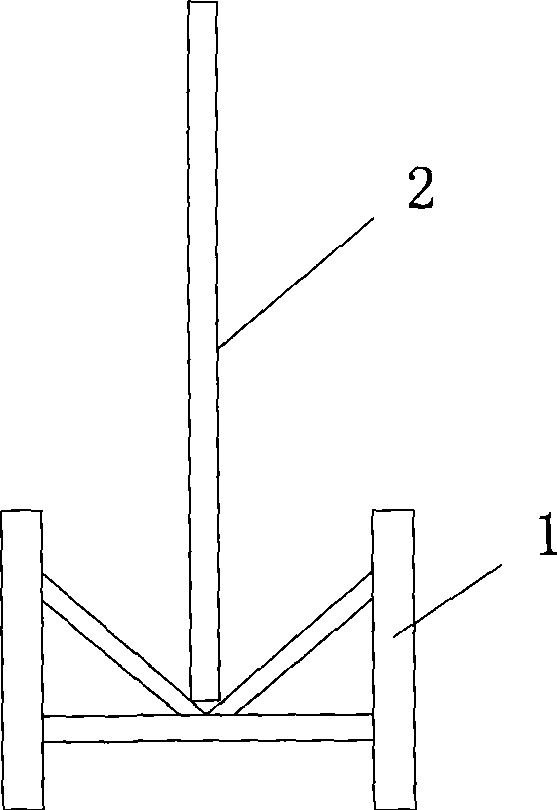

Top clamp type side shielding apparatus for electroplating printed circuit board

ActiveCN101372755APlay the role of coveringAvoid hittingPrinted circuit manufactureEngineeringPrinted circuit board

The invention provides an electroplated lateral shielding device for a top-clamp type printed circuit board. Two ends of a ship-shaped baffle are respectively provided with a pair of lateral baffles; each lateral baffle is provided with a sliding chute; the lateral baffles are connected with the ship-shaped baffle by connecting rods; one end of each connecting rod is fixedly connected on the ship-shaped baffle by a fixed shaft, while the other end of each connecting rod is connected on each sliding chute by a movable shaft; and weights leading the lateral baffles to maintain low gravity center are fixed on the lateral baffles. The invention can reduce invalid production, reduce material waste, reduce the partial difference between setting thickness by electroplating and actual operation, and meet the control requirement of electroplating evenness.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

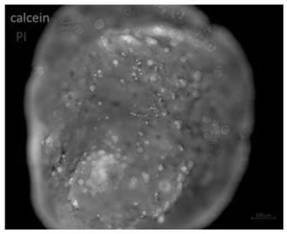

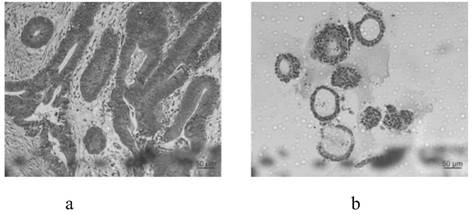

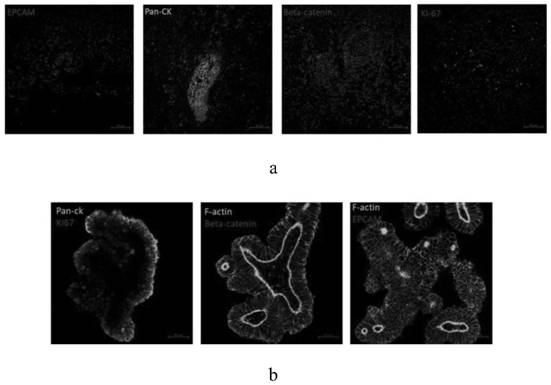

Culture method for colorectal cancer organoids and culture solution

ActiveCN112266898ALow costSimple and fast operationGastrointestinal cellsCulture processFormularyOncology

The invention relates to a culture method for colorectal cancer organoids and a culture solution. Culture media use cell lines producing Wnt-3a, R-Spondin1 and Noggin to replace the addition of threeexpensive cytokines, so that the costs of culturing organoids can be saved to a utmost extent compared with the formulas of organoid culture media in literature, and success rate can reach more than 90%. The culture solution can culture the tumor tissue derived from the colorectum of patients. The culture method is simple in operation; passage can be realized in five days; solutions do not need tobe changed frequently within five days; and tedious operation can be reduced, and the costs can be saved.

Owner:SOUTH CHINA UNIV OF TECH

Method and equipment for detecting stress resistance of display screen

ActiveCN103809311AReduce display unevennessThe problem of uneven screen display is reducedNon-linear opticsComputer scienceImage display

The invention provides a method and equipment for detecting the stress resistance of a display screen. The method comprises the following steps: enabling the display screen to be detected to be in an undriven state and carrying out vacuum adsorption on the surface of the display screen for preset time; carrying out statistics on time that color spots disappear on the display screen after vacuum adsorption is finished; and comparing the time that the color spots disappear with a threshold value of the time that the color spots disappear, if the time that the color spots disappear is less than or equal to the threshold value, judging the stress resistance of the display screen is qualified, or judging the stress resistance of the display screen is unqualified. By the method provided by the invention, the display screen of which the stress resistance accords with the requirement can be screened in advance; the higher the stress resistance of the display screen is, the difficult the problem of nonuniform image display of a touch control display module, which is caused by variation of the thickness of a box due to nonuniform partial stress, is to generate in the process of subsequently attaching to a touch screen, and thus, the method provided by the embodiment reduces the probability of generating the problem of nonuniform image display of the module and reduces waste of cost.

Owner:TRULY OPTO ELECTRONICS

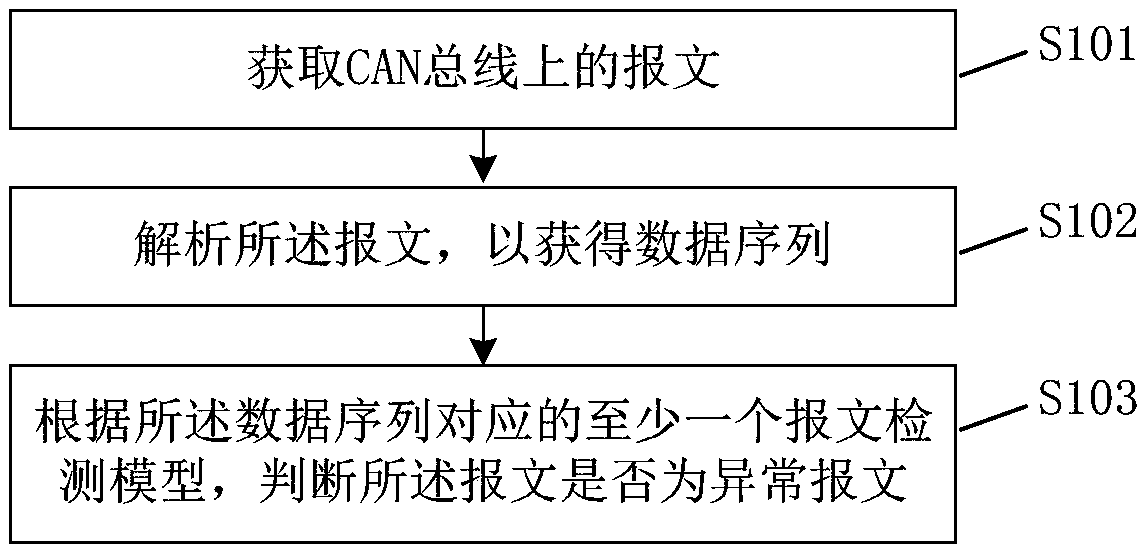

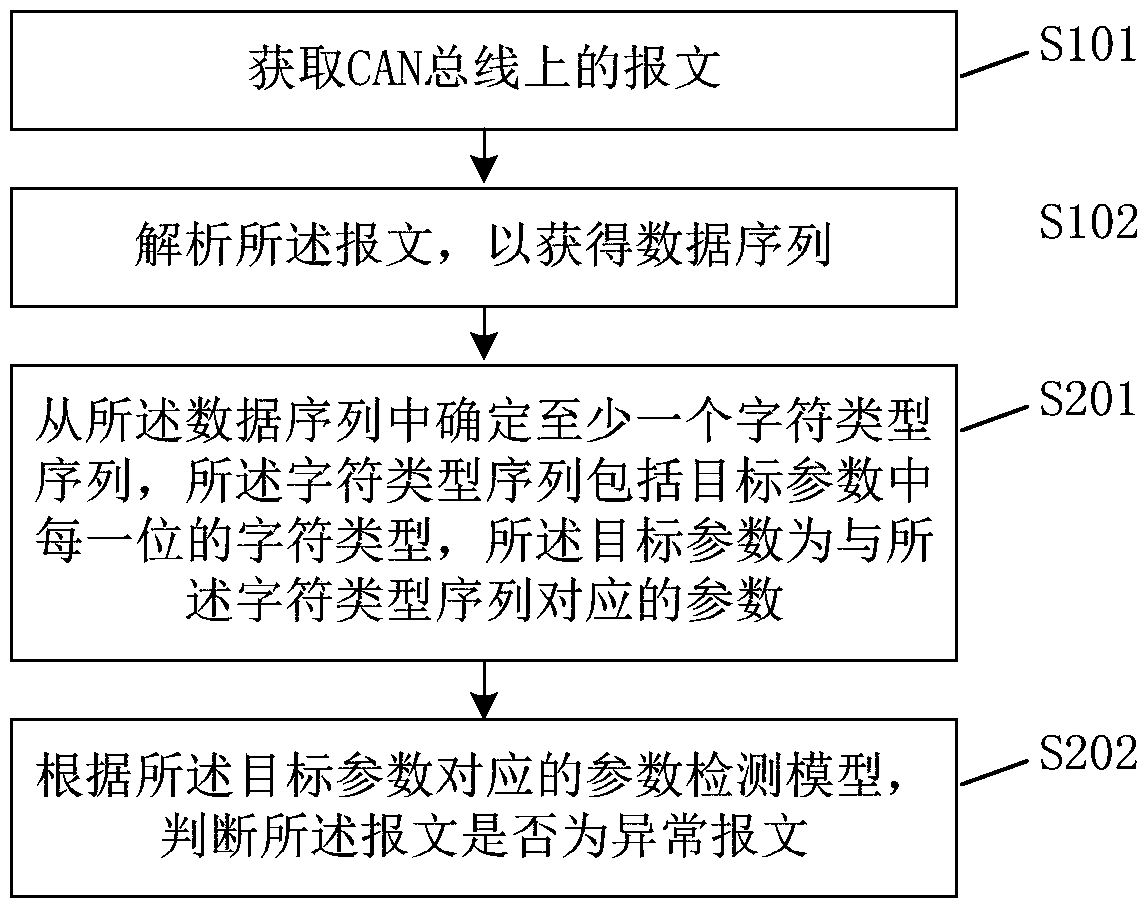

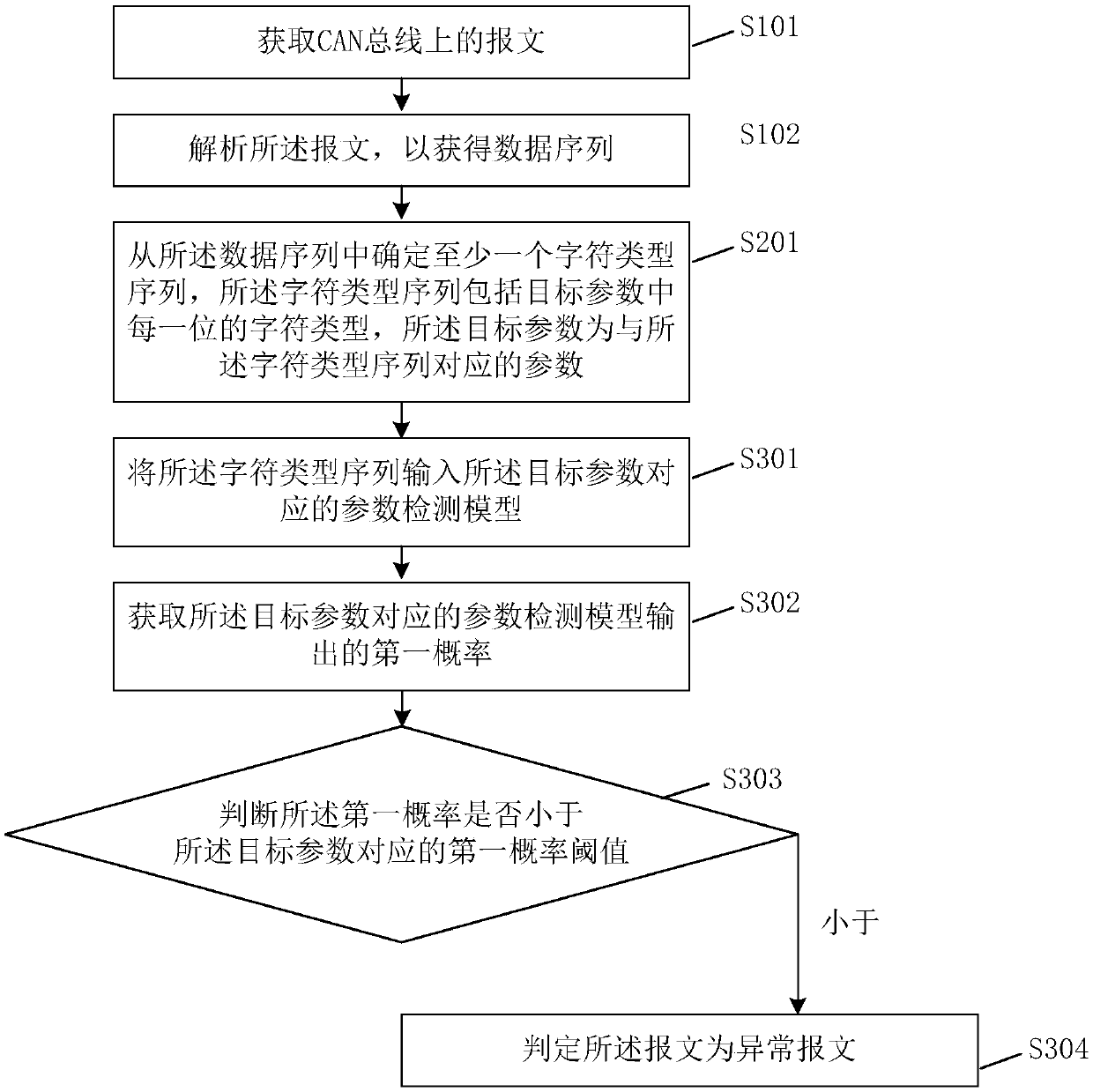

Message detection method, device, equipment and storage medium

ActiveCN109688030AAvoid bypassingAvoid false positivesBus networksData sequencesComputer engineering

The embodiment of the invention provides a message detection method and device, equipment and a storage medium. The method includes the following steps: acquiring a message on a CAN bus; analyzing themessage to obtain a data sequence; and judging whether the message is an abnormal message according to at least one message detection model corresponding to the data sequence, wherein the message detection model is obtained by training a sample data sequence in a sample message. According to the technical scheme of the embodiment of the invention, abnormal messages at the instruction level and the parameter level can be identified, unknown intrusion behaviors can be found, bypasses and omissions can be avoided, and the cost waste caused by manual maintenance rules can be reduced.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

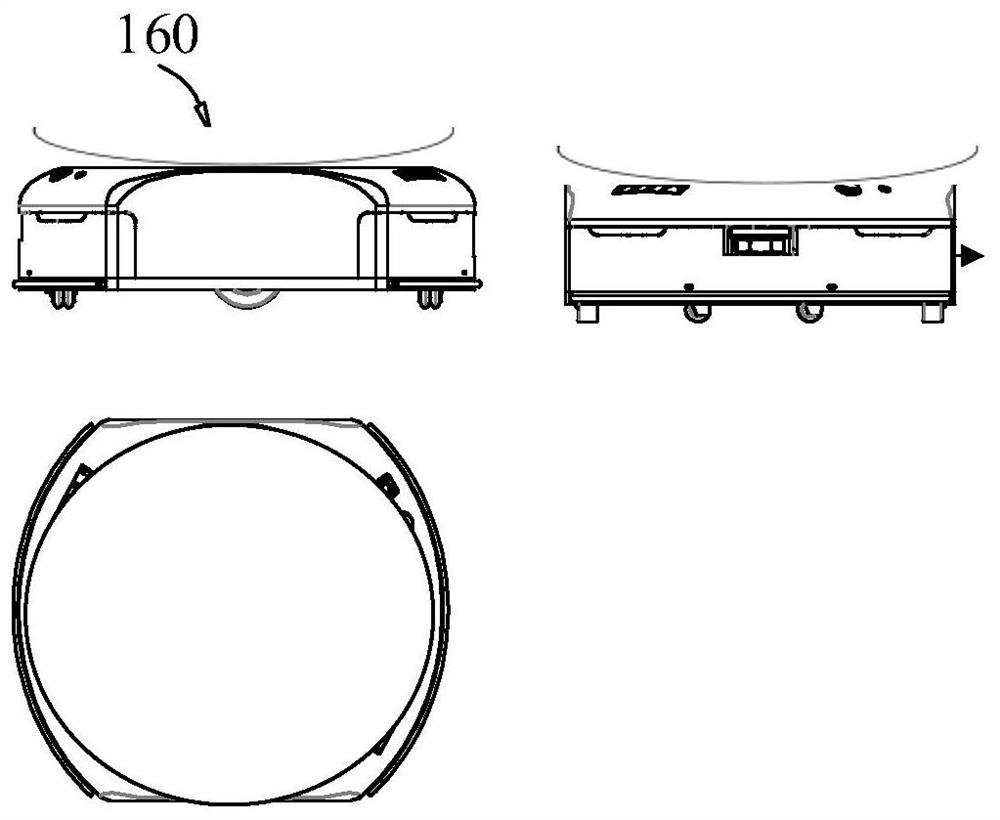

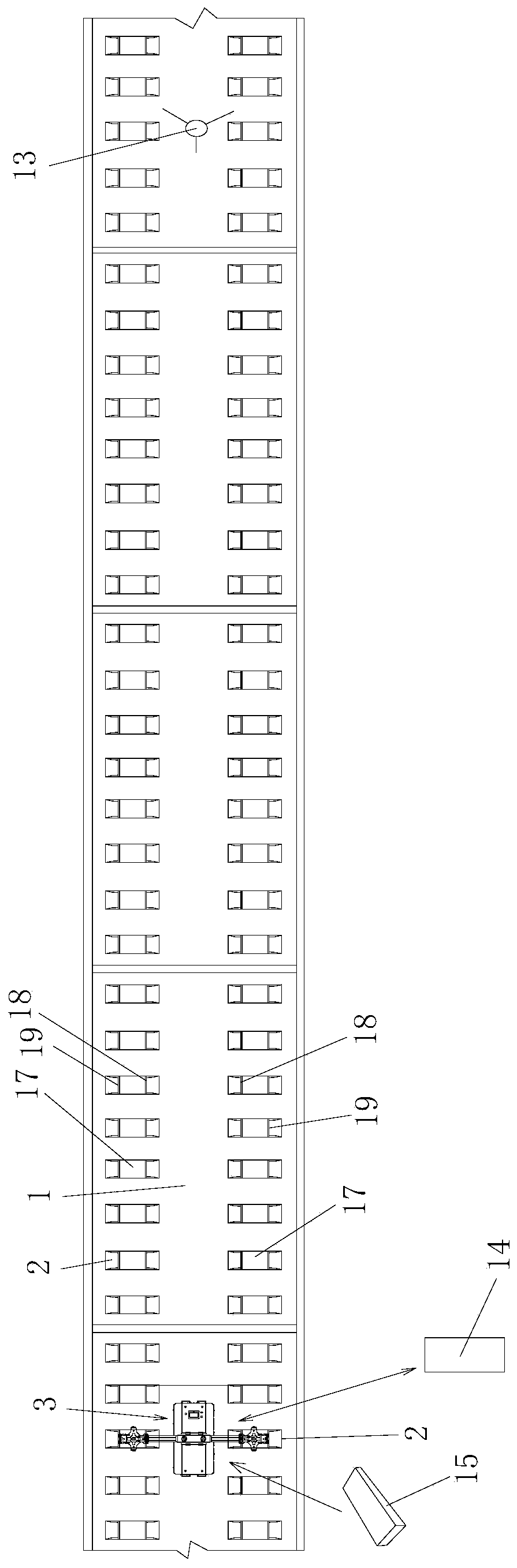

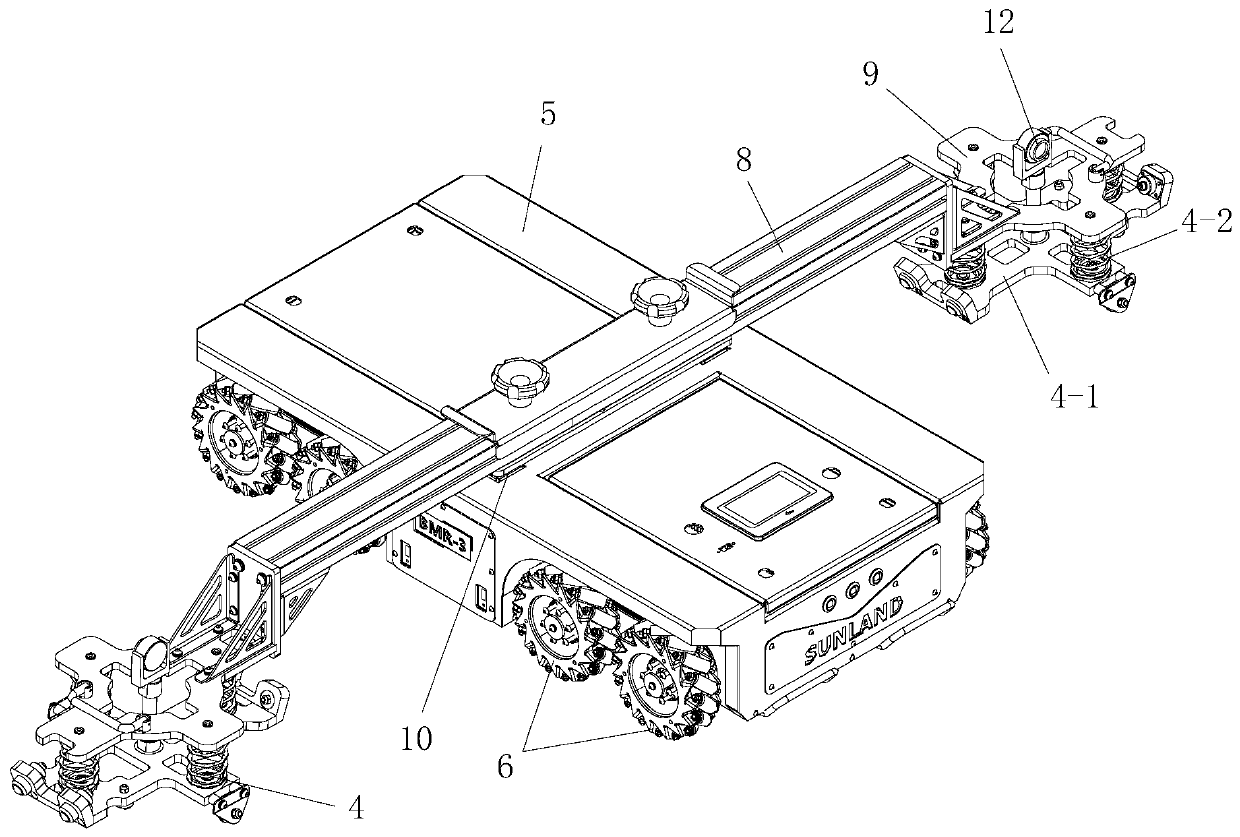

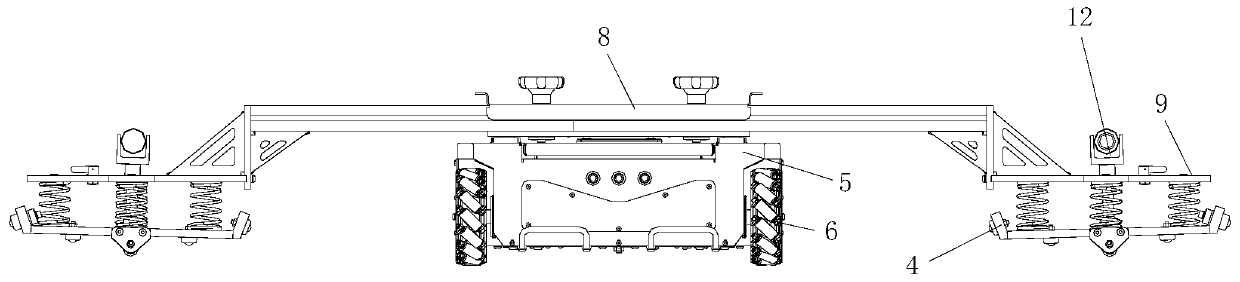

Automatic detection equipment and an automatic detection method for a ballastless track bearing platform

PendingCN109706804ASimple structureReasonable designMeasuring apparatusAutomatic test equipmentEngineering

The invention discloses automatic detection equipment and an automatic detection method for a ballastless track bearing platform. The automatic detection equipment comprises a track bearing platform detection robot. The track bearing platform detection robot comprises a vehicle body, a left clamping mold, a right clamping mold, a mold mounting frame and a lifting mechanism for driving the mold mounting frame to move up and down. Each clamping mold is provided with a detection tool. The method comprises the following steps: 1, preparation work before detection; 2, forward translation of the detection robot and synchronous detection of the track bearing platforms. According to the invention, the track bearing platforms on the ballastless track to-be-detected are detected one by one by the track bearing platform detection robot; the left track bearing platform and the right track bearing platform which are positioned on the same cross section of the ballastless track to-be-detected can besynchronously detected, so the track bearing platform detection efficiency can be greatly improved, the construction period is effectively shortened, the detection result is accurate, meanwhile, thetrack bearing platforms can be detected before the operation track is installed, and various problems existing in detection after the operation track is installed are effectively solved.

Owner:西安远景智能控制有限公司

Beam type full-automatic casting machine

ActiveCN106312031APrecise positioningAccurate horizontal positioningMolten metal supplying equipmentsCasting parameters measurement/indication devicesEngineeringMechanical engineering

The invention provides a beam type full-automatic casting machine. The beam type full-automatic casting machine comprises a support, a large crane mechanism movably arranged on the support, a small crane mechanism movably arranged on a cross beam of the large crane mechanism, a lifting system, a slewing mechanism arranged at the bottom of the lifting system, a weighing mechanism arranged on the slewing mechanism, a tilting mechanism arranged on the weighing mechanism, a ladle frame arranged on the titling mechanism and a tilting frame which is driven by the tilting mechanism and can pivot relative to the ladle frame, wherein the top of the lifting system is arranged on the small crane mechanism, and a machine frame of the tilting mechanism is provided with a stream inoculation device, a temperature measuring system and a video system. The beam type full-automatic casting machine can achieve fixed-point quantitative constant-speed high-quality casting.

Owner:NINGXIA KOCEL MOLD

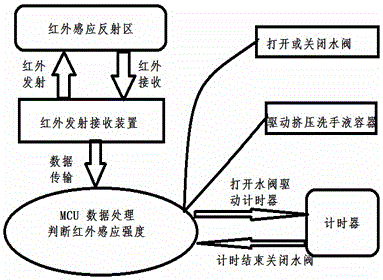

Intelligent hand washing machine

InactiveCN106725034AGuaranteed dosageAvoid closingHolders and dispensersAgricultural engineeringEngineering

The invention discloses an intelligent hand washing machine. The intelligent hand washing machine comprises a hand washing body, wherein the hand washing machine is provided with a water outlet which is connected to a tap water pipeline, a water outlet infrared induction device, a hand washing liquid opening and hand washing liquid opening infrared induction device, the water outlet is connected to the water outlet infrared induction device, and the hand washing liquid opening is connected to the hand washing liquid opening infrared induction device. Compared with the prior art, according to the intelligent hand washing machine, a water discharging system and a hand washing liquid releasing system are integrated on the hand washing machine; at the same time, an automatic induction water discharging function is time limited by a control terminal, secondary pollution during hand washing process is avoided, the problem of water waste is greatly overcome at the same time, unnecessary cost waste is saved, and the intelligent hand washing machine is more environmentally friendly, more hygienic and safer.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

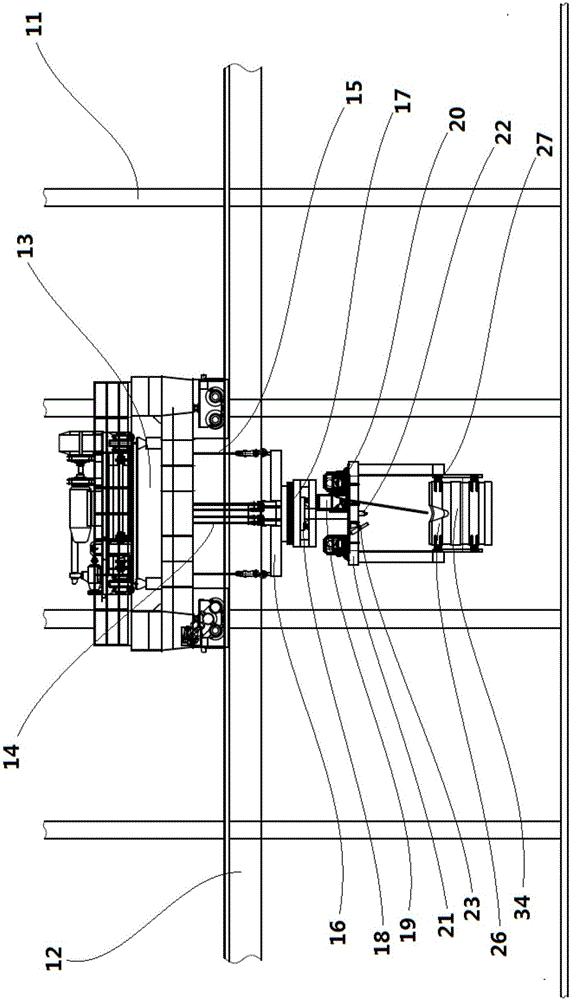

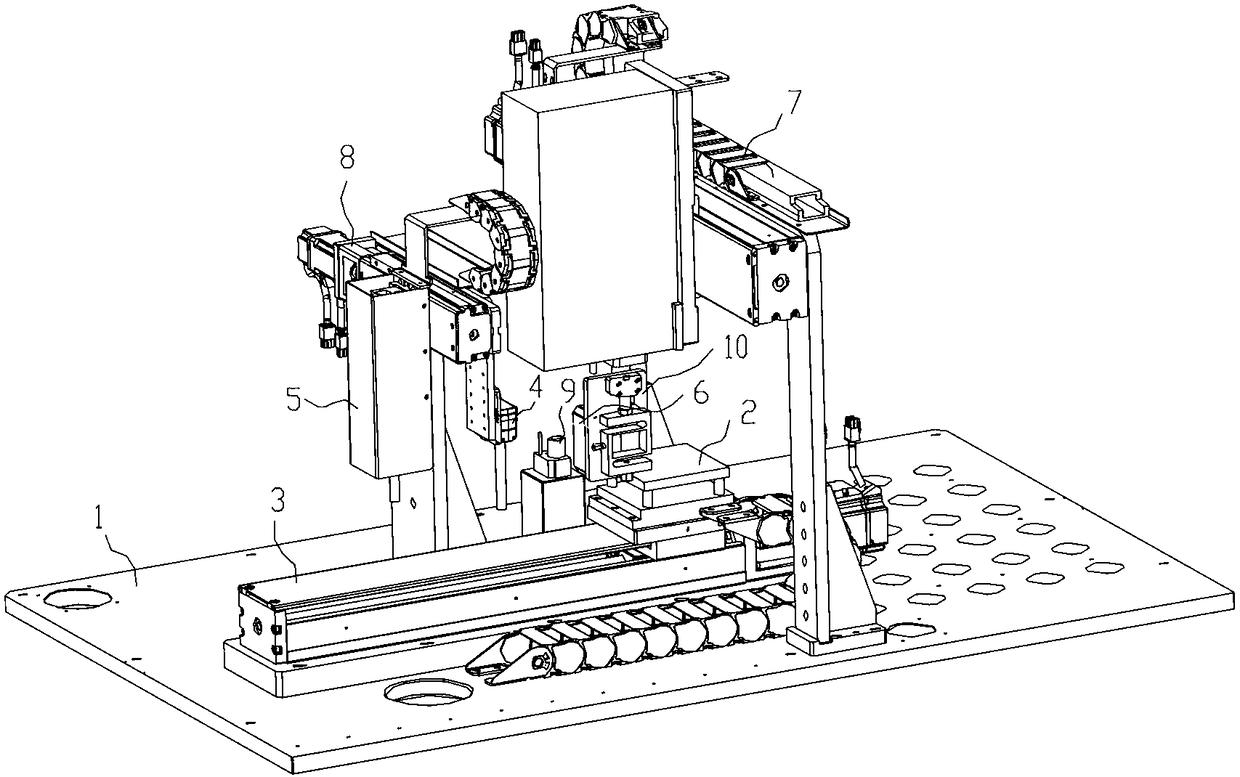

Dual-camera module correction device and correction method thereof

The invention discloses a dual-camera module correction device and a correction method thereof. The correction device comprises an operation platform, and at least one group of correction stations isarranged on the operation platform; a jig heating platform, an X axis movement device, a code scanner, a CCD positioning mechanism, an altimeter and a pressing mechanism are arranged on each correction station; a dual-camera module is fixed on the jig heating platform, the jig heating platform is installed on the X axis movement device, and the CCD positioning mechanism, the code scanner, the altimeter and the pressing mechanism are all arranged above the movement direction of the X axis movement device. According to the dual-camera module correction device, a machine is used for repairing defective products, thereby having a high degree of artificial intelligence and high repair precision, saving the manpower and the machine platform cost, and greatly shortening the product repair cycle.

Owner:深圳眼千里科技有限公司

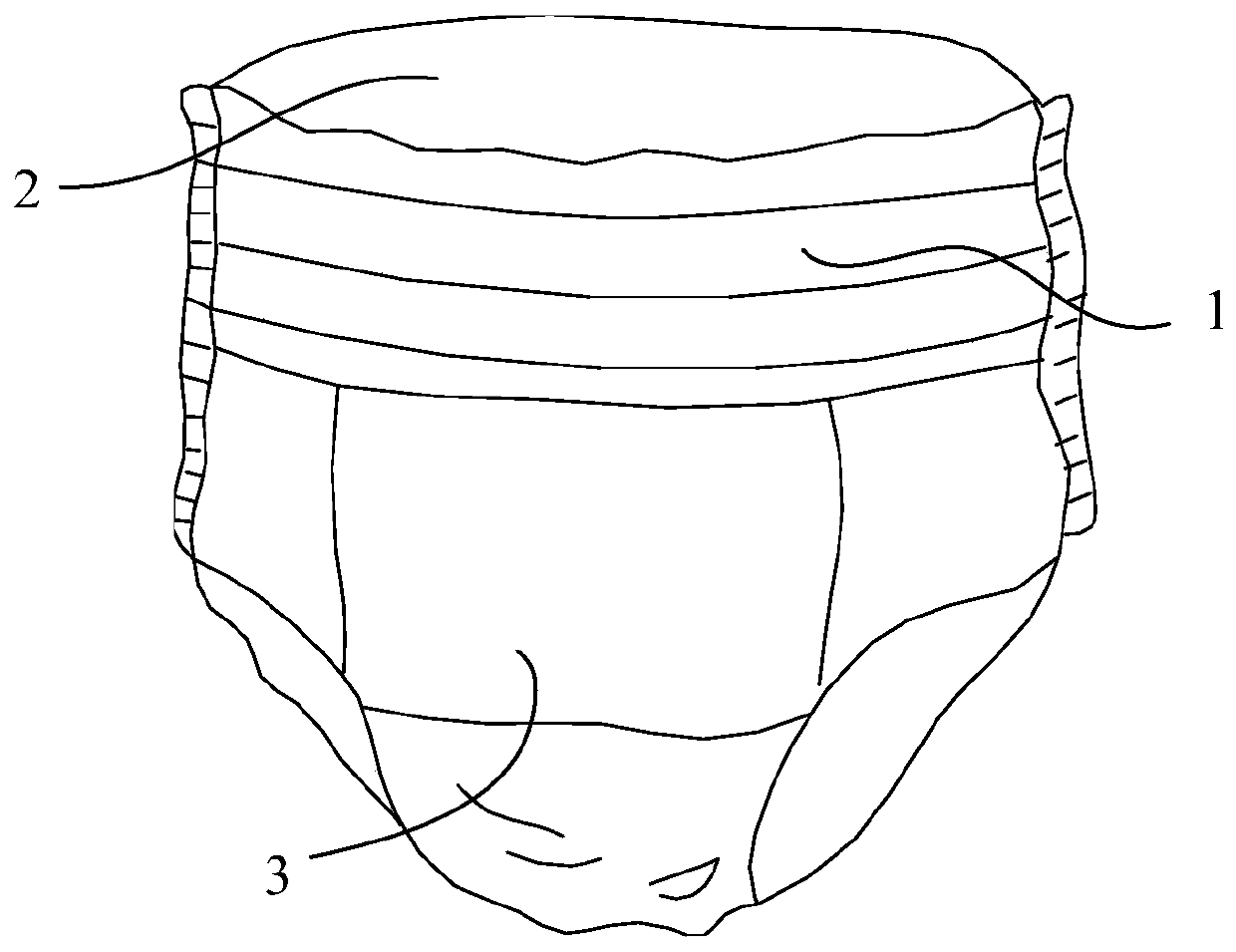

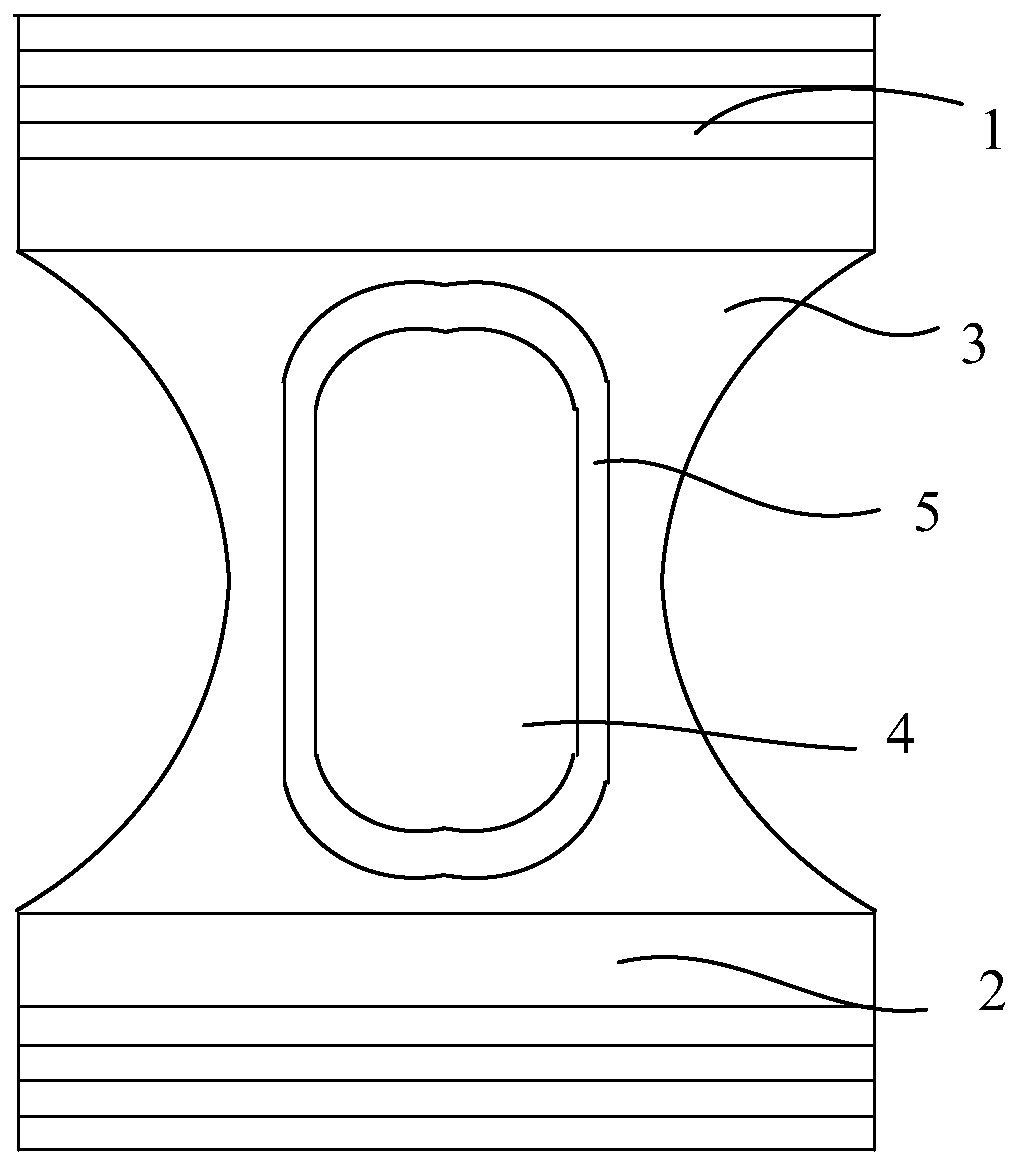

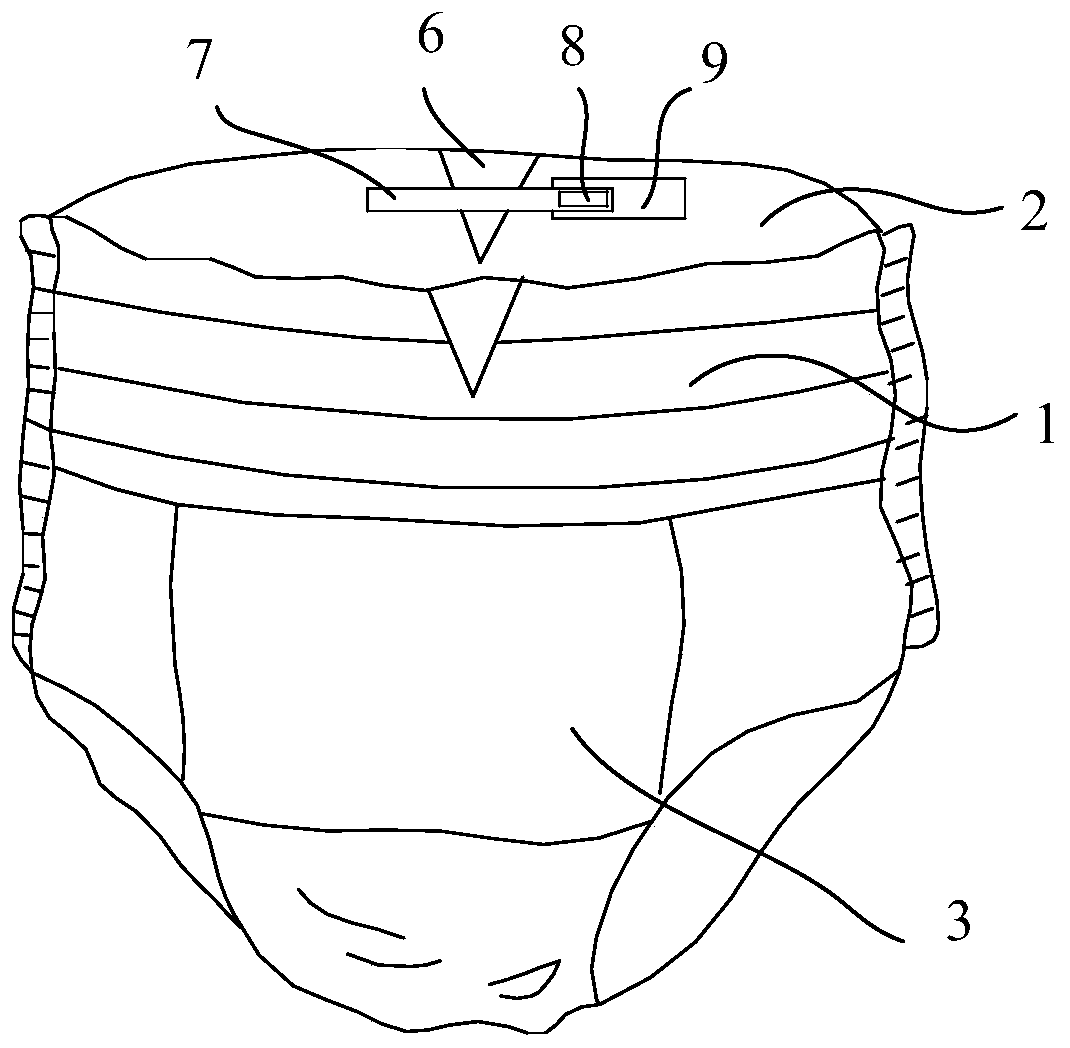

Pull-ups for adults

PendingCN110037859AReduce edemaReduce hematomaAbsorbent padsTherapeutic coolingCold compressesUltrasonic welding

The invention discloses pull-ups for adults, belongs to the technical field of medical-grade health products and aims at solving the problems that lying-in women suffer from perineum edemas and hematomas after operation and the treatment area of a cold compress cushion is small in the prior art. The pull-ups comprise a front waist part, a crotch part and a rear waist part, two ends of the crotch part are connected with the front waist part and the rear waist part respectively, and the pull-ups also comprise a magnesium sulfate cushion and a cold compress cushion; and two side edges of the front waist part and the two side edges of the rear waist part are sewn together by ultrasonic welding, the middle of the crotch part is detachably connected with the cold compress cushion, the cold compress cushion is a strip extending from the front waist part to the rear waist part, and the magnesium sulfate cushion is detachably connected with the upper surface of the cold compress cushion. The pull-ups realize the technical effects as follows: edemas and hematomas of perineum of lying-in women are effectively reduced, the treatment area for focuses is larger, the comfort level of the pull-upsis improved and the cold compress range is enlarged.

Owner:田小波 +1

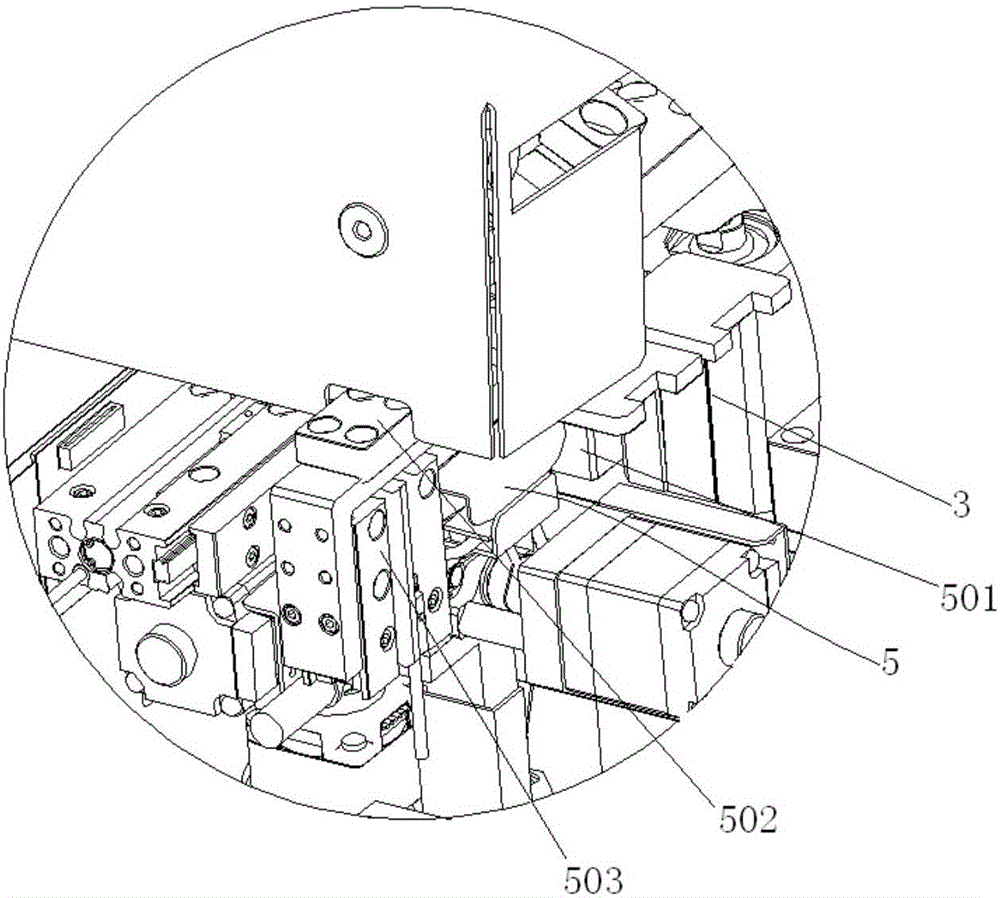

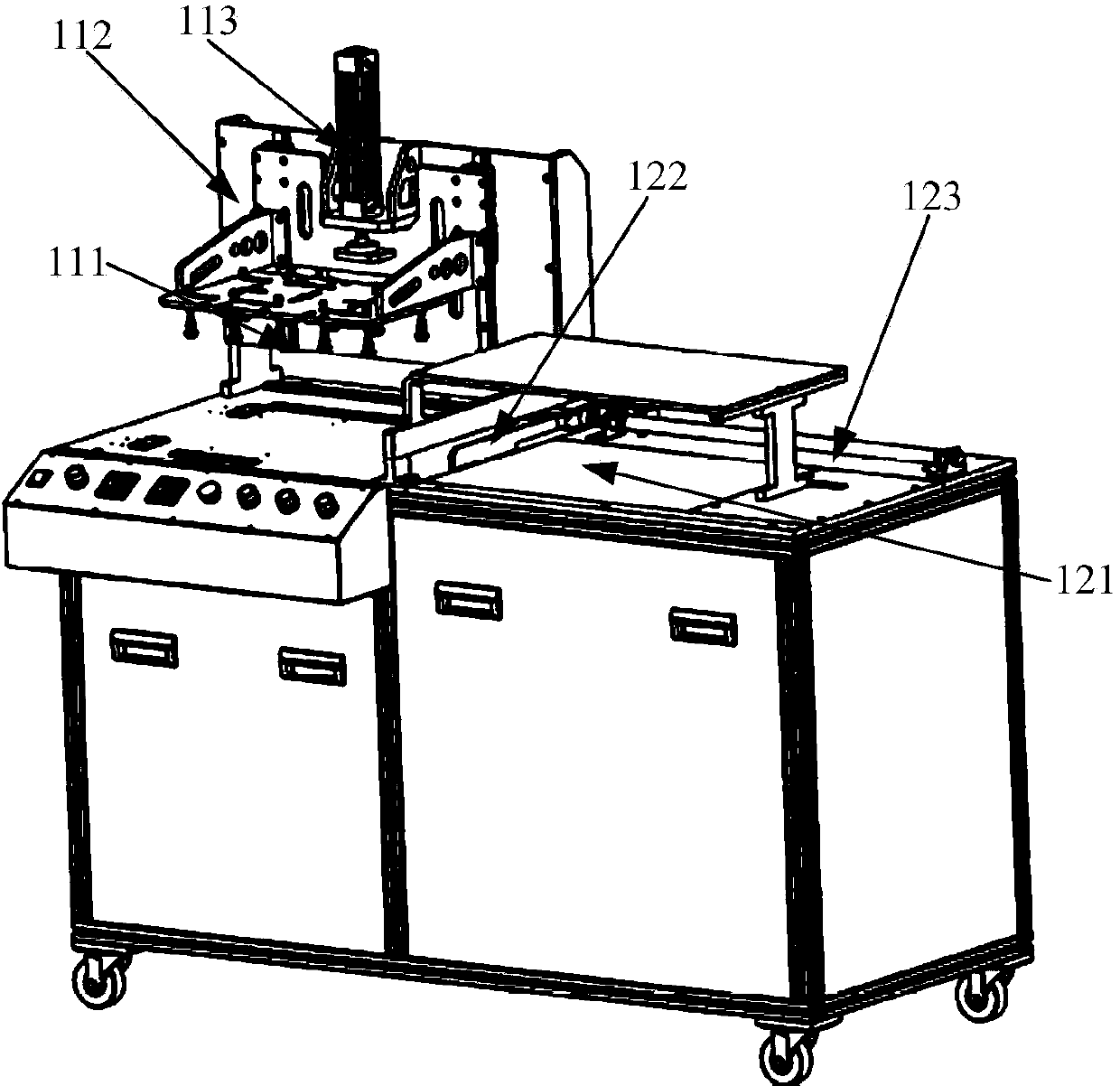

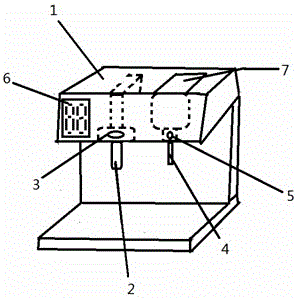

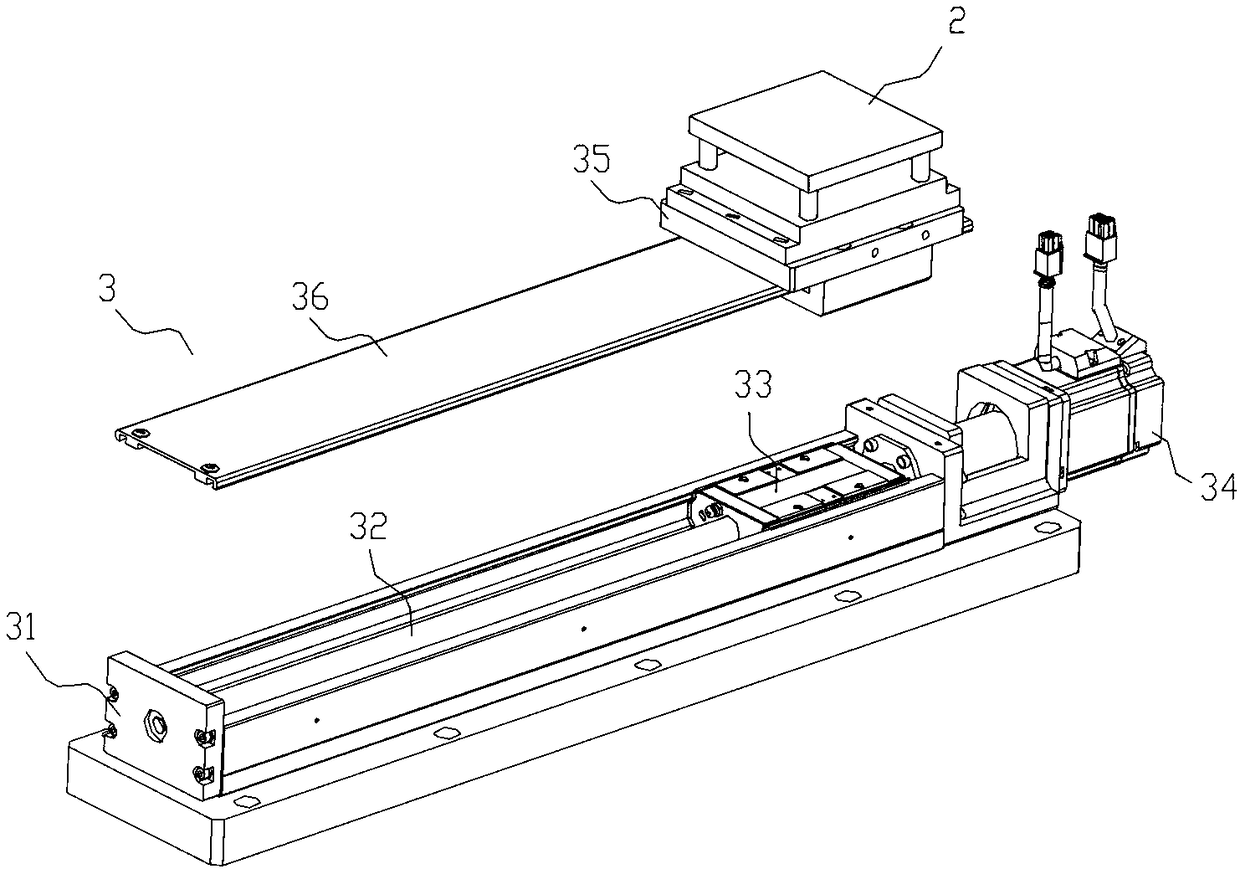

Testing and burning integrated machine platform for camera module

The invention discloses a testing and burning integrated machine platform for a camera module. Three rotary tables and a test window are arranged on a test platform in sequence, a plurality of testing and burning mechanisms are arranged on each rotary table, and the plurality of testing and burning mechanisms can be rotated and positioned at positions aligned to the test window by a driving source; three test board mechanisms are arranged on an operating platform in sequence, two left and right test board mechanisms realize left and right moving and positioning functions by product moving mechanisms, and to-be-measured camera modules on the three test board mechanisms are vertically rotated by product overturning mechanisms to face to the testing and burning mechanisms in the test window to start testing and OPT burning and other works. According to the integrated machine platform provided by the invention, one person can simultaneously operate 6 stations in 3 workstations, thereby efficiently saving the manpower and hardware cost wastes, greatly shortening the production cycle of products and improving the uniformity and various performance of the products.

Owner:KUNSHAN Q TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com