Method and equipment for detecting stress resistance of display screen

A display screen and anti-stress technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as cost loss and uneven screen display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a method for testing the stress resistance capability of a display screen, the method comprising the following steps:

[0029] Step S1: Keep the display screen to be tested in an undriven state, and perform vacuum adsorption on the surface of the display screen for a preset time.

[0030] During the vacuum adsorption process of the display screen, the adsorption point on the display screen is continuously subjected to stress, which will cause the cell thickness of the liquid crystal cell at this position to be gradually greater than that of the non-absorbed area.

[0031] In this embodiment, the display screen to be detected may be a display screen with a polarizer attached, or a display screen without a polarizer attached.

[0032] The duration of vacuum adsorption on the display screen (that is, the preset time) is not limited, and the preset time can preferably be determined according to actual quality requirements for the display screen. Si...

Embodiment 2

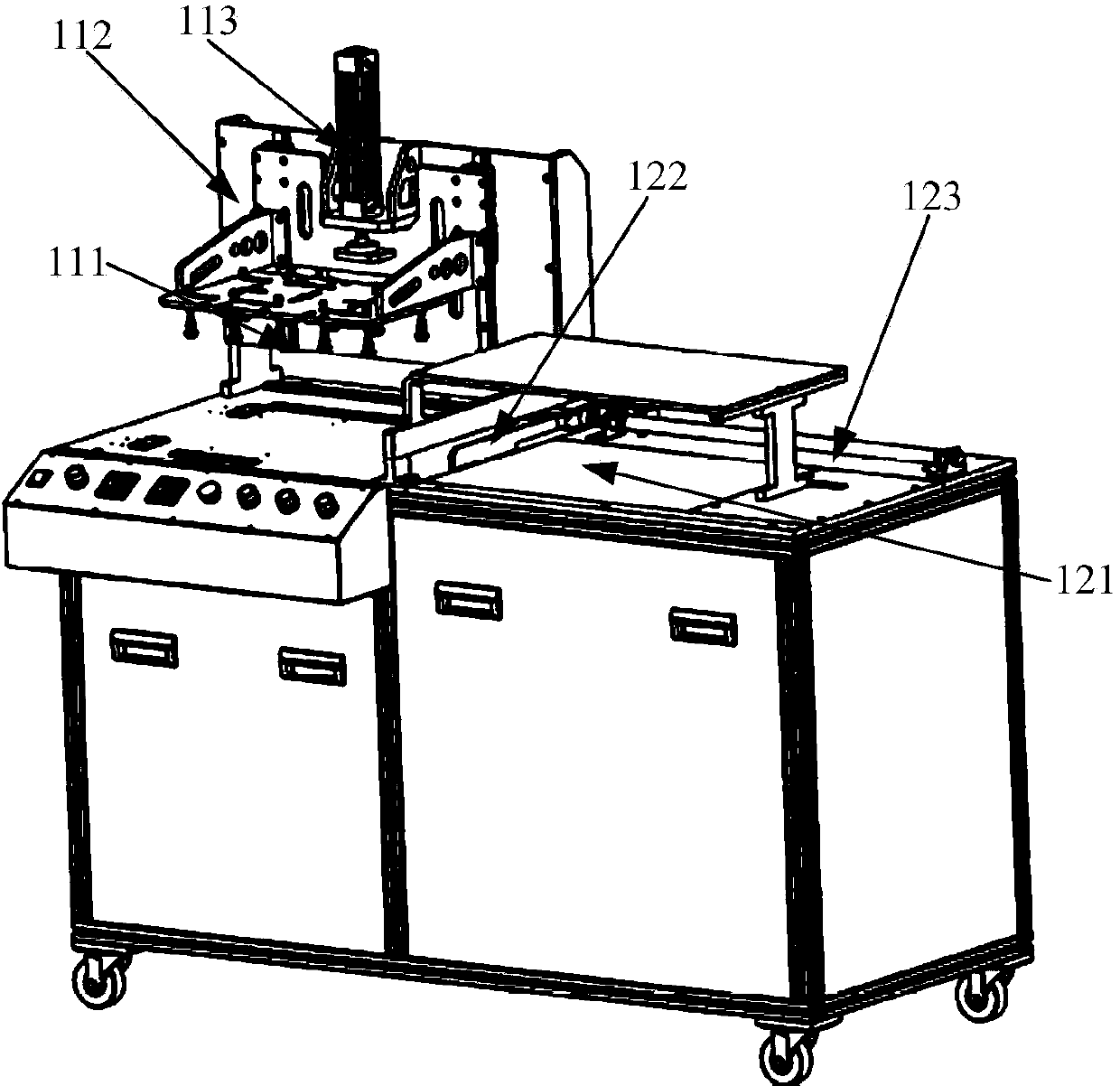

[0046] Corresponding to the above method embodiments, this embodiment provides a device for testing the stress resistance capability of the display screen, the structure of the device is as follows figure 1 As shown, it includes: a vacuum nozzle 111 , a first guide rail 112 and a first cylinder 113 .

[0047] In order to further improve the functions of the above-mentioned equipment, the above-mentioned equipment may further include: a backlight 121; in order to further improve the degree of mechanical automation of the above-mentioned equipment, the above-mentioned equipment may further include: a second guide rail 122 and a second cylinder 123.

[0048] The device for testing the stress resistance capability of the display screen provided in this embodiment can be divided into two parts: a vacuum adsorption area and an adjacent observation area. The vacuum suction area is used to carry out vacuum suction operation on the display screen, including: vacuum suction nozzle 111, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com