Vacuum assistance system detection method, vacuum assistance system detection system, electromobile and failure detection method

A vacuum boosting and detection method technology, which is applied in the direction of brake safety system, etc., can solve the problems of poor vacuuming effect, vacuum pump not working, and inability to vacuum the vacuum tank, etc., so as to prolong the service life, ensure safe driving, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

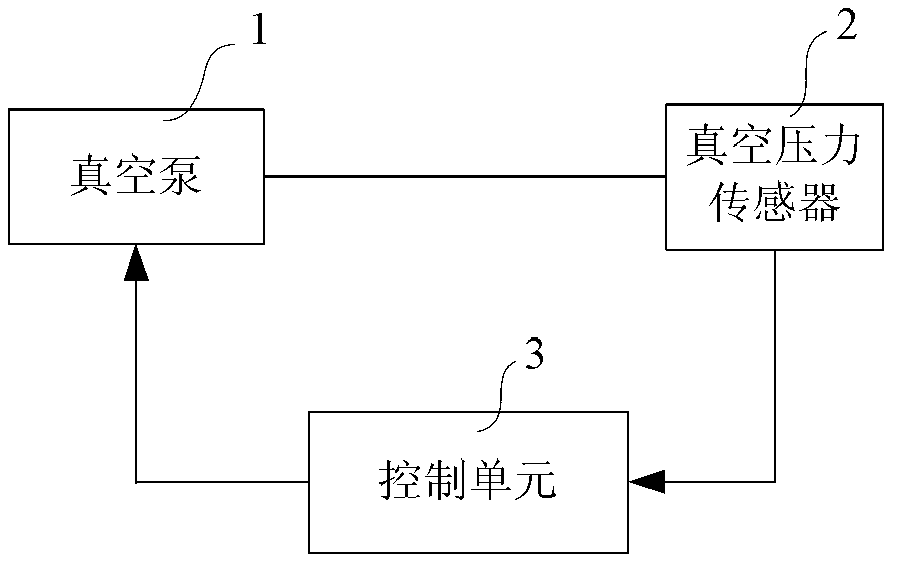

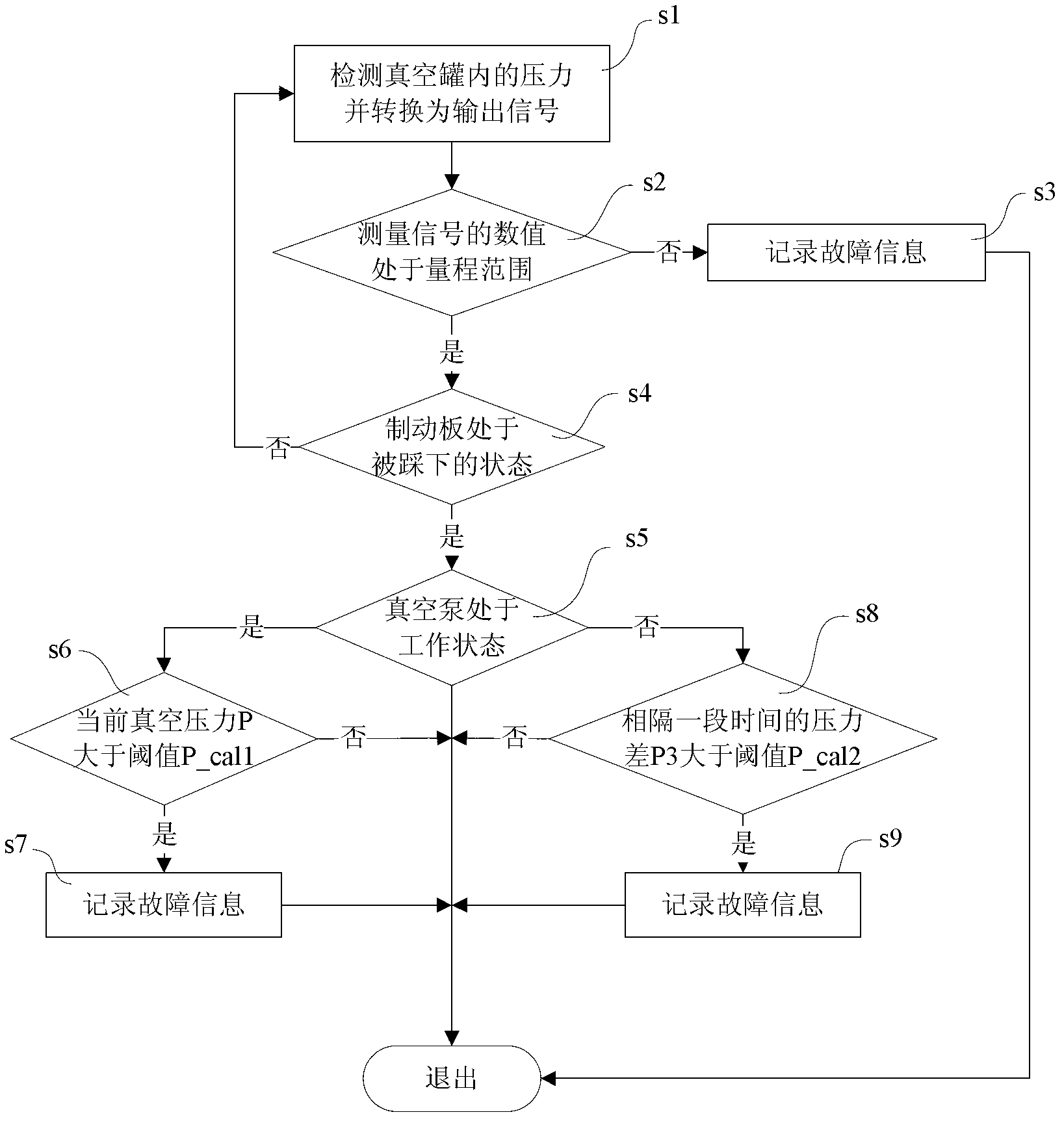

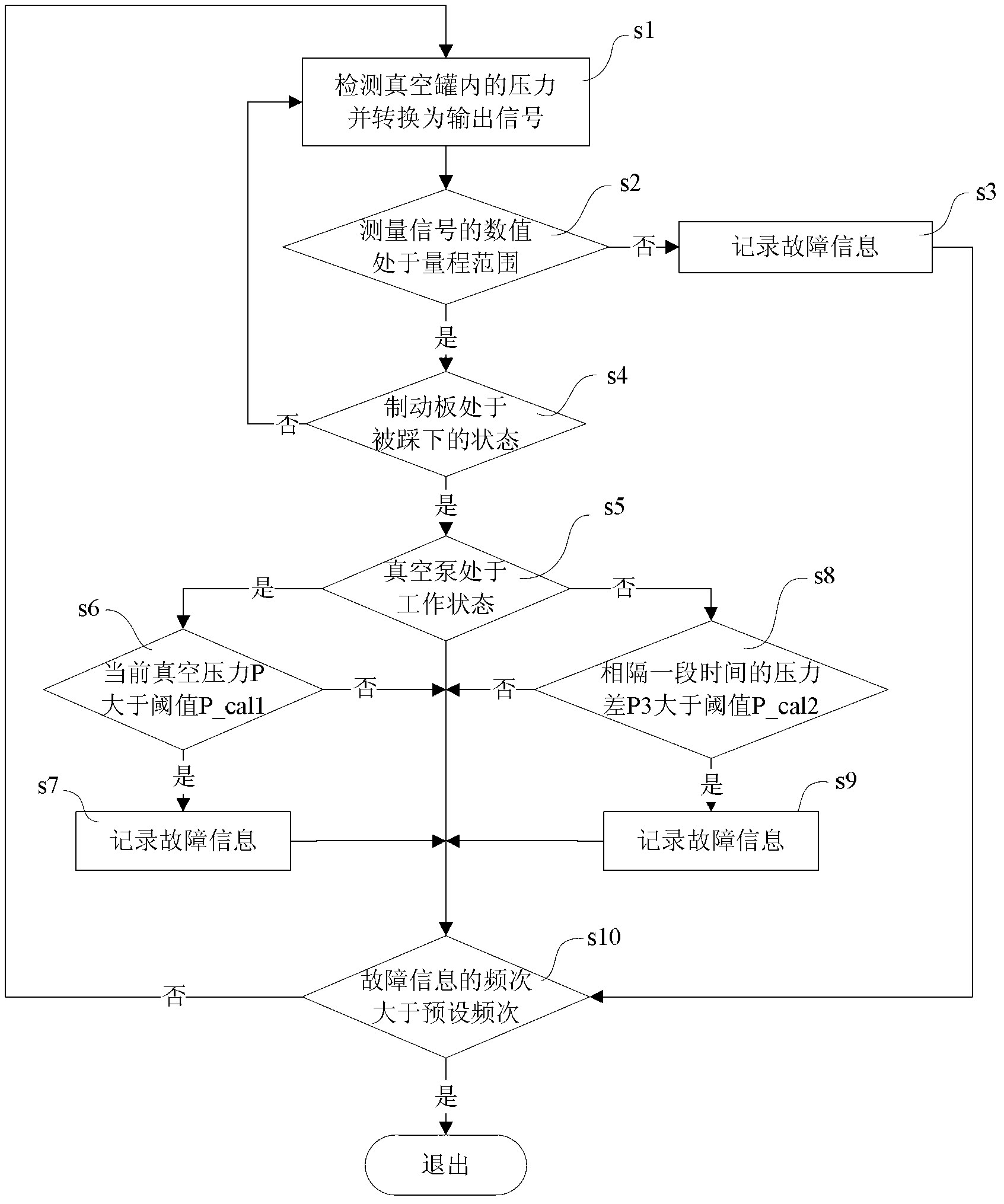

[0049] In order for those skilled in the art to better understand the technical solution of the present invention, the vacuum booster system detection method and system, the electric vehicle fault detection method and the electric vehicle provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0050] Such as figure 2 As shown, the vacuum boosting system detection method provided by Embodiment 1 of the present invention includes the following steps:

[0051] Step s1 is the detection step. Specifically, the pressure sensor detects the pressure in the vacuum tank, and outputs a measurement signal representing the pressure in the vacuum tank. Wherein, the measurement signal may be a voltage signal or a current signal.

[0052] Step s2 is the step of diagnosing the pressure sensor. Specifically, by judging whether the value of the measurement signal is within the range of the pressure sensor, it is judged whether the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com