Integrated automatic assembly machine stand for double-camera module

An automatic assembly, dual-camera technology, used in mechanical equipment, devices for coating liquids on surfaces, material gluing, etc., can solve problems such as transportation costs and increase efficiency, save labor and hardware cost waste, and improve consistency. The effect of shortening the production cycle of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to be able to understand the technical content of the present invention more clearly, the following examples are given to illustrate in detail, the purpose of which is only to better understand the content of the present invention and not to limit the protection scope of the present invention.

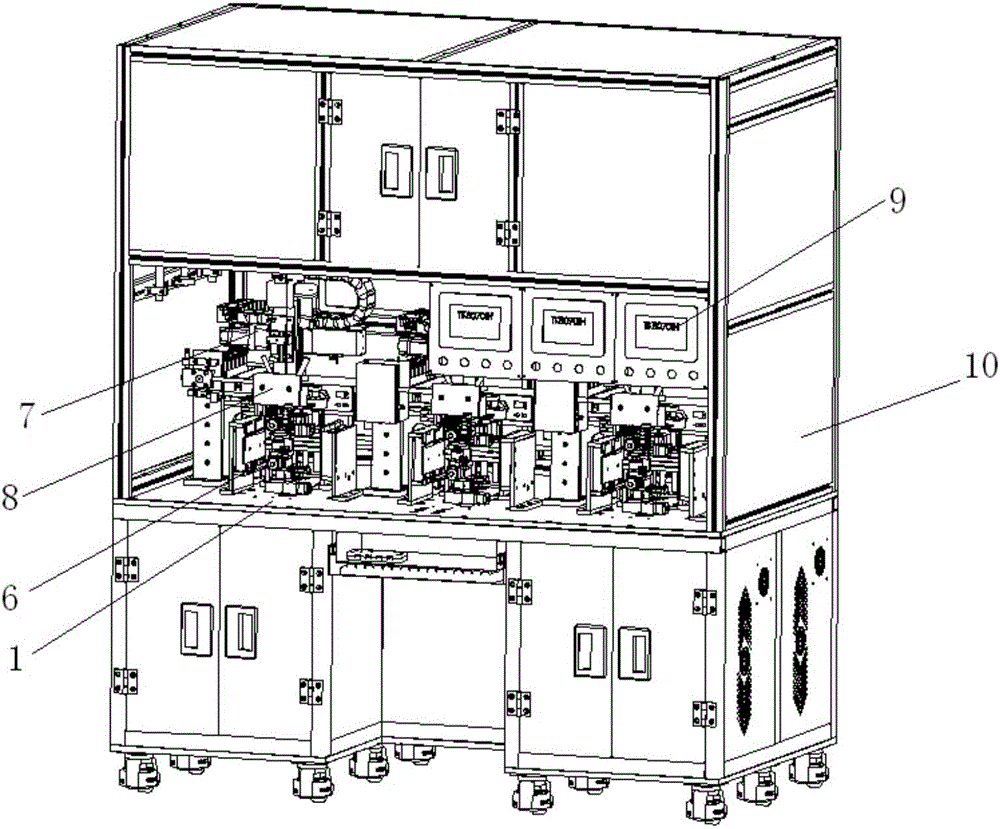

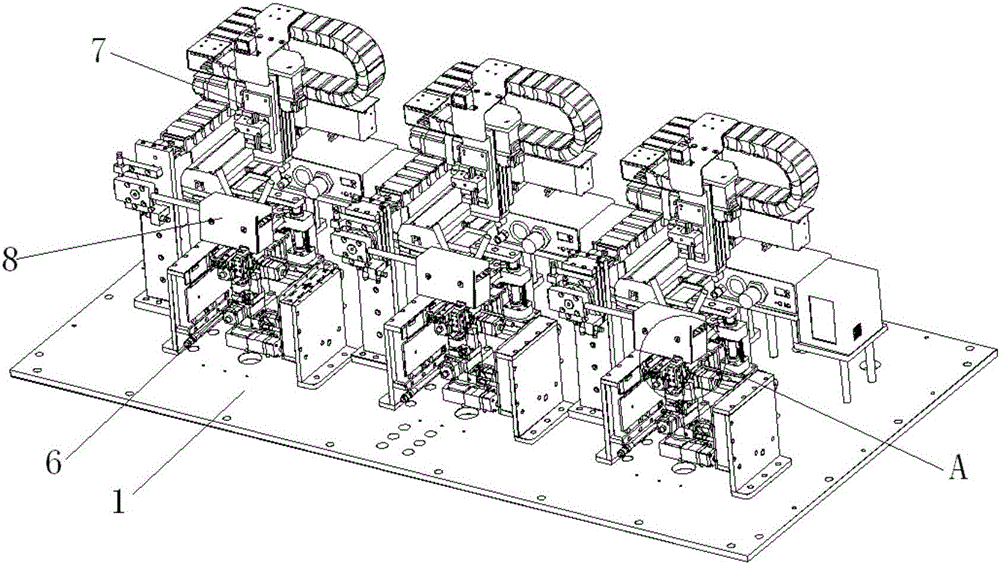

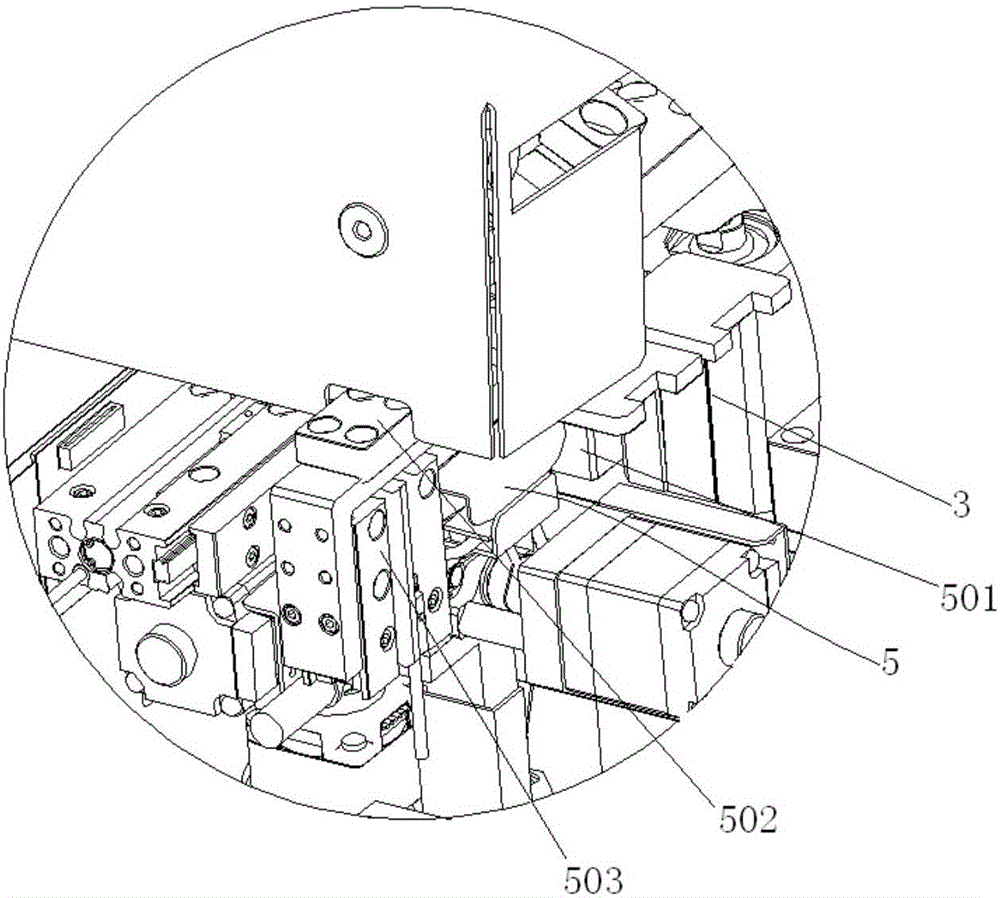

[0025] like figure 1 , figure 2 and image 3 As shown, an integrated machine for automatic assembly of dual-camera modules includes an operating platform 1, and at least one operating station is provided on the operating platform. Corresponding to each operating station, there is a The main camera fixing mechanism 3, the auxiliary camera fixing mechanism 5 used for supporting and positioning the auxiliary camera 4, and the auxiliary camera fixed on the auxiliary camera fixing mechanism 5 is used for six-axis adjustment, so that its central axis is the same as the main camera. A six-axis adjustment mechanism 6 whose central axes are parallel to each other, a UV dispen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com