Method for restricting midpoint potential drifting of three-level inverter in direct drive wind power system

A three-level inverter, wind power system technology, applied in wind power generation, irreversible DC power input conversion to AC power output, electrical components, etc. Drift etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

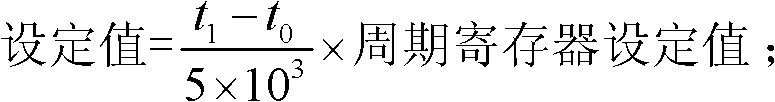

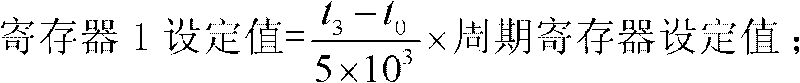

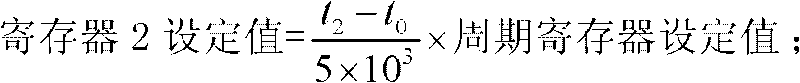

Embodiment Construction

[0026] 1. Selection of boost inductor for three-level Boost converter

[0027] Compared with the conventional Boost converter, the three-level Boost converter in the present invention also has discontinuous conduction mode (DCM) and continuous conduction mode (CCM). The continuous conduction mode can be divided into inductor independent energy supply mode and inductor. -Capacitor power supply mode. The working mode of the converter mainly depends on the size of the boost inductor. When the load condition remains relatively stable and the switching frequency remains constant, the critical inductance is only related to the duty cycle d (when the difference is not equal to π, it is called the boost ratio). Since the present invention designs a controllable switching signal phase difference method to suppress the midpoint potential drift, the influence of the switching signal phase difference θ should be considered when calculating the critical inductance between different working m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com