Flexible printed circuit whole board punching method

A flexible circuit board, full-page technology, used in printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as inability to assemble, customer complaints about costs, product offsets, etc., to facilitate product assembly, reduce cost waste, The effect of improving yield

Active Publication Date: 2010-03-31

深圳市合力泰光电有限公司

View PDF0 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the need for two times of punching, the deviation of the mold itself and the deviation of the two sets of molds caused by the punching connection will cause some products to be punched off, and the punched connection point will protrude from the original shape of the product, resulting in customer assembly. Bad, can't assemble

This kind of bad flow to the customer will be complained by the customer and cause unnecessary cost loss

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0016] Production with conventional process: copper foil cutting → NC drilling → black hole copper plating → line forming → cover film → hot pressing → immersion gold → shape stamping → electrical measurement → SMT → punching connection points → etc. to make 1000 pieces of double-sided The flexible circuit board is then punched with the full-page punching method for the flexible circuit board of the present invention, which is denoted as A1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

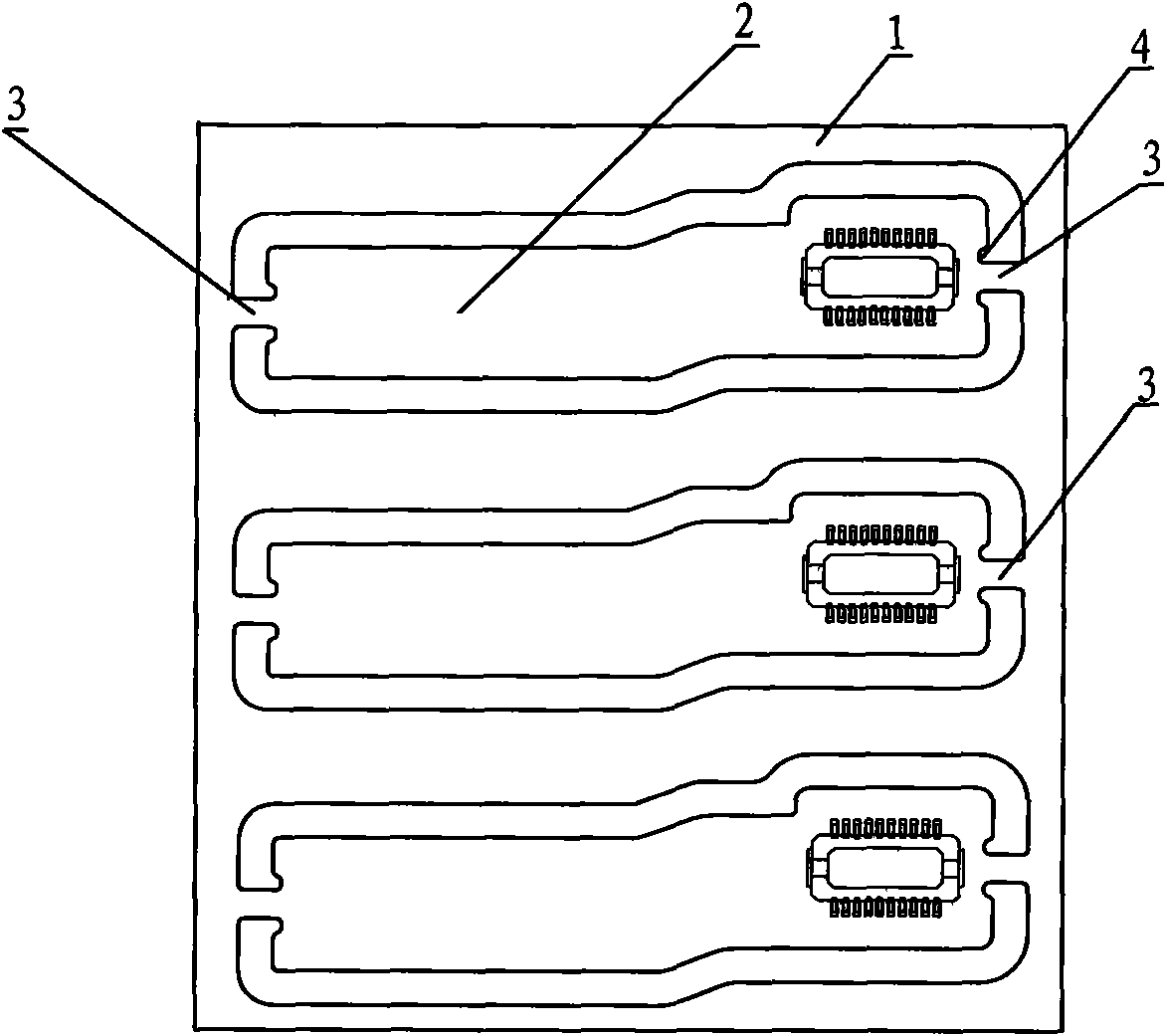

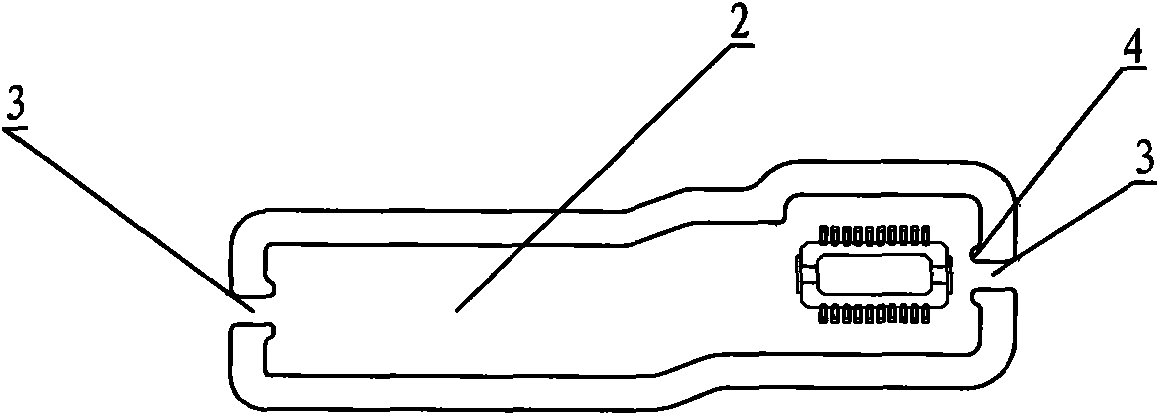

The invention provides a flexible printed circuit whole board punching method, the method adopts a flexible printed circuit whole board, a first mould and a second mould; wherein the first mould comprises at least one first punch head compatible to the shape of the flexible printed circuit; the second mould comprises at least one second punch head used for punching the joint part of the flexible printed circuit; the joint part comprises at least one groove the two sides of which are lower than the shape of product. The method includes that the flexible printed circuit whole board is fed into the processing area of the first mould and the first punch head is utilized to punch the shape of the circuit board; the second punch head of the second mould is used for punching the joint part of theflexible printed circuit, thus forming the flexible printed circuit. The flexible printed circuit whole board punching method of the invention adopts the punch head of the first mould to punch the shape of flexible printed circuit board product, then the punch head of the second mould is used for punching the joint part of the flexible printed circuit, thus not only improving yield of products, but also reducing unnecessary cost waste, thereby being beneficial for product assembly.

Description

technical field [0001] The invention relates to a flexible circuit board, in particular to a full-page punching method for a flexible circuit board. Background technique [0002] Flexible circuit board is the most complex and versatile circuit board product, especially because it has the characteristics of light, thin, short, bendable, low voltage, low power consumption, etc., and can be 3D Three-dimensional wiring in space, so it is widely used in electronic products such as notebook computers, liquid crystal displays, hard disks, printers and automobiles. [0003] At present, when flexible circuit board manufacturers conduct mass production of flexible circuit boards, they need to arrange a batch of flexible circuit boards together on a whole flexible circuit board, and then separate the individual flexible circuit boards into one piece by punching technology. One die cut down. Because the product needs to be carried by SMT (Surface Mount Technology), in order to facilit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H05K3/00B26F1/38B21D28/02

Inventor 韩芹周群

Owner 深圳市合力泰光电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com