Aluminum profile surface spraying device and operation method thereof

A technology of surface spraying and operation method, which is applied in the field of aluminum profile processing, can solve the problems affecting the overall flatness, poor uniformity, and low efficiency of aluminum profile spraying, so as to reduce cost waste, improve spraying quality, and improve spraying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

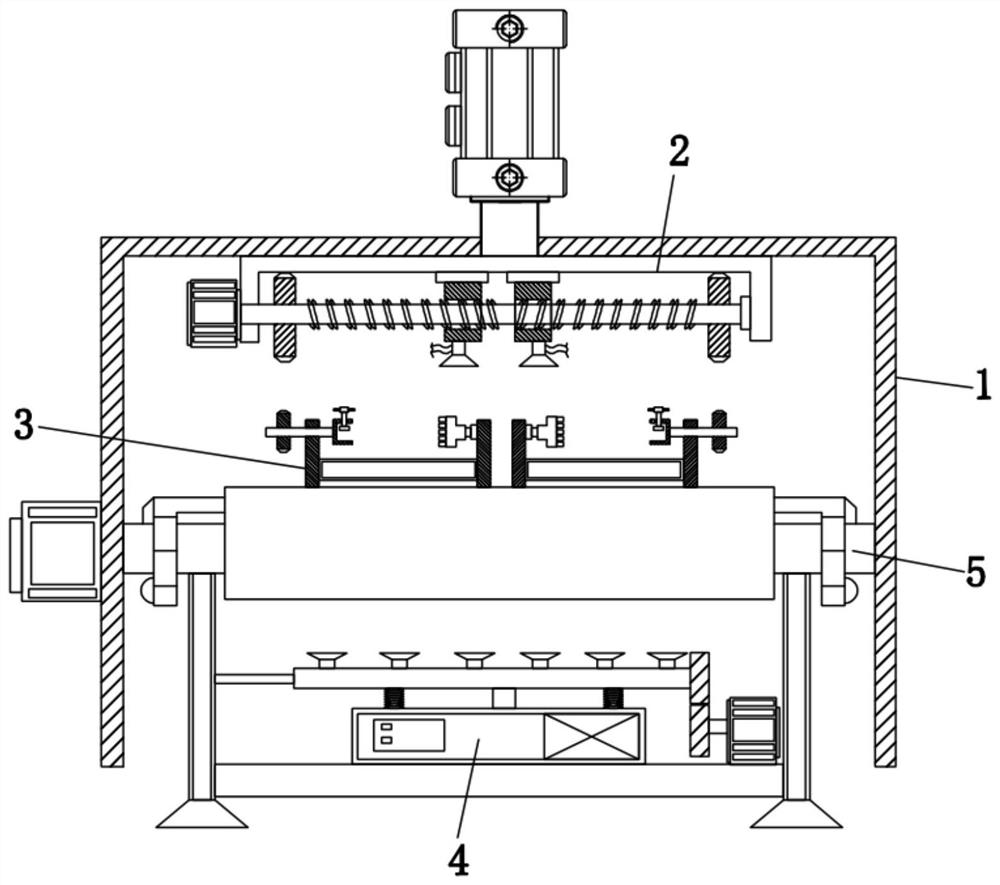

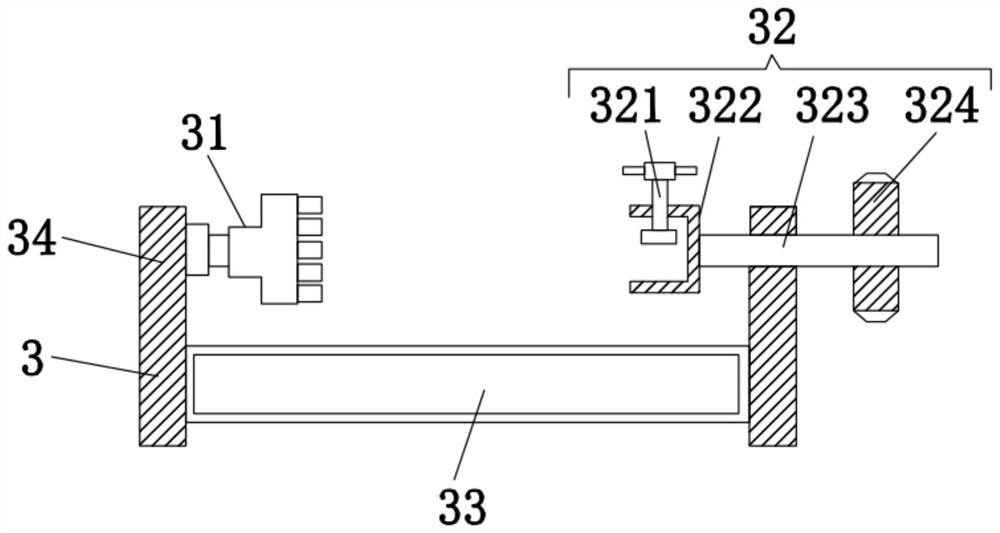

[0036] Embodiment 1, see Figure 1-6 , the present invention provides a technical solution: an aluminum profile surface spraying device, comprising: a housing 1, a spraying mechanism 2 is installed at the top of the inner cavity of the housing 1, a conveyor belt 5 is installed in the inner cavity of the housing 1, and the conveyor belt 5 is located at the spraying The lower end of the mechanism 2 and the top of the conveyor belt 5 are equipped with several clamping mechanisms 3. Through the cooperation of the clamping mechanism 3 and the spraying mechanism 2, the aluminum profile can be flipped and sprayed at the same time, and the aluminum profile can be fully sprayed and conveyed. The inner bottom end of the belt 5 is equipped with a drying mechanism 4, through which the sprayed aluminum profiles can be dried.

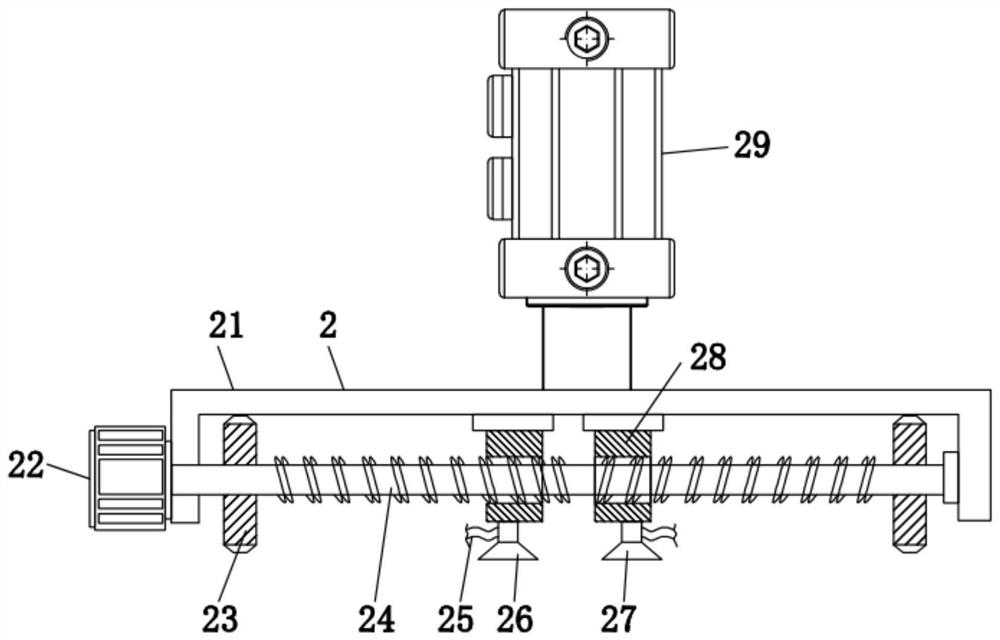

[0037]More specifically, the spraying mechanism 2 includes a fixed box 21, a motor one 22, a gear one 23, a lead screw 24, a spraying liquid connecting pipe 25, a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com