Warehouse management system and method

A warehouse management system and target storage technology, applied in data processing applications, comprehensive factory control, instruments, etc., can solve the problem of low delivery efficiency and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

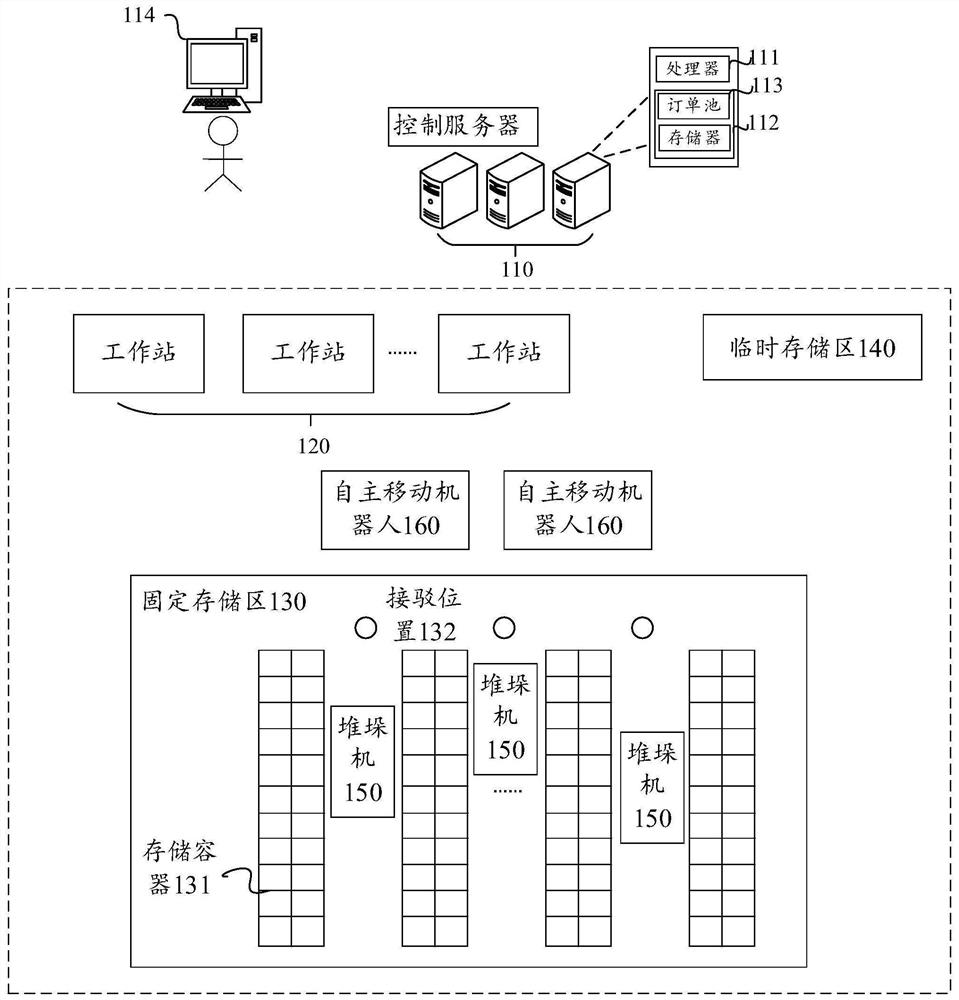

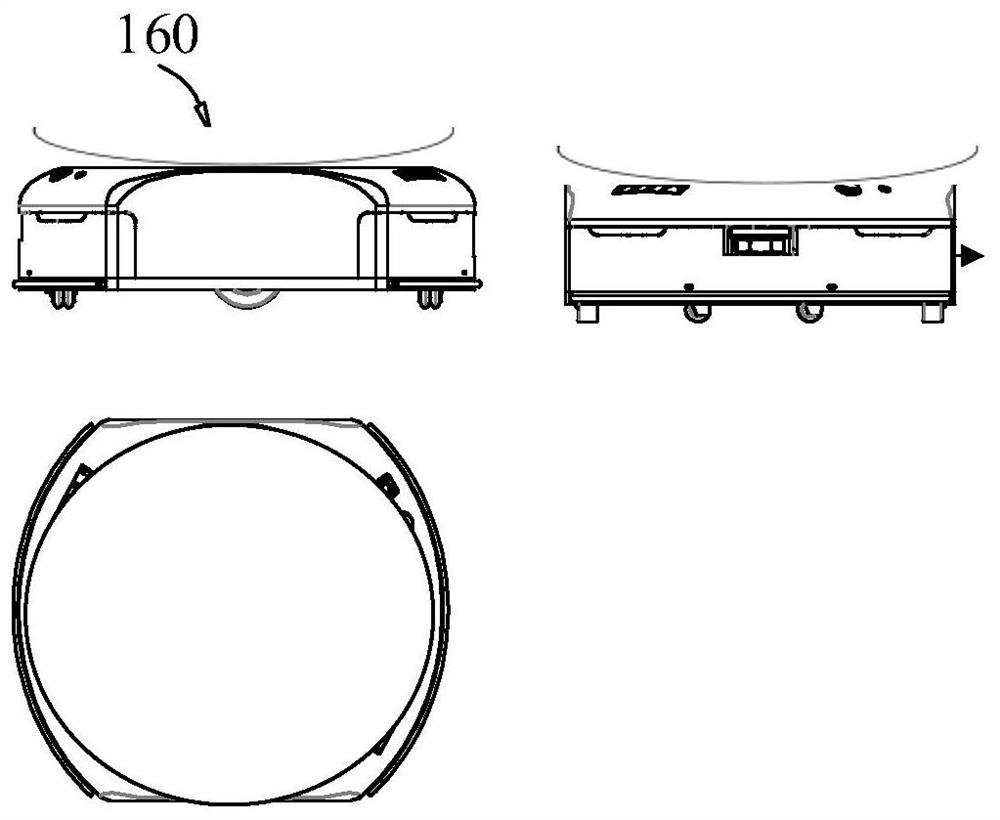

[0079] A warehouse management system provided in the embodiment of the present application, such as figure 1 As shown, the system includes a control server 110, a workstation 120, a fixed storage area 130, a temporary storage area 140, a stacker 150, and an autonomous mobile robot 160. In the fixed storage area 130, there are storage containers 131 and docking positions 132. The connecting position 132 is located at the junction of the fixed storage area 130 and the workstation 120, and the distance between the temporary storage area 140 and the workstation 120 is less than or equal to a preset threshold; wherein,

[0080] The control server 110 is configured to determine the target storage container 1311 hit by the first order and the first storage location 1301 of the target storage container 1311 in the fixed storage area 130 according to the first order in the order group information, and determine the take-out target The first target stacker 1501 for the storage container...

Embodiment 2

[0114] This embodiment provides another implementation of the storage system, such as figure 1 As shown, the system includes: one or more control servers 110, a plurality of workstations 120, a fixed storage area 130, a plurality of temporary storage areas 140, one or more automatic access systems, and the automatic access systems include high racks and The stacker 150 running on the high shelf, a plurality of autonomous mobile robots 160, have storage containers 131 and connection positions 132 in the fixed storage area 130, and the connection position 132 is located between the fixed storage area 130 and At the junction of the workstation 120, the distance between the temporary storage area 140 and the workstation 120 is less than or equal to a preset threshold; wherein,

[0115] The control server 110 is configured to determine the target storage container 1311 hit by the first order and the first storage location 1301 of the target storage container 1311 in the fixed stora...

Embodiment 3

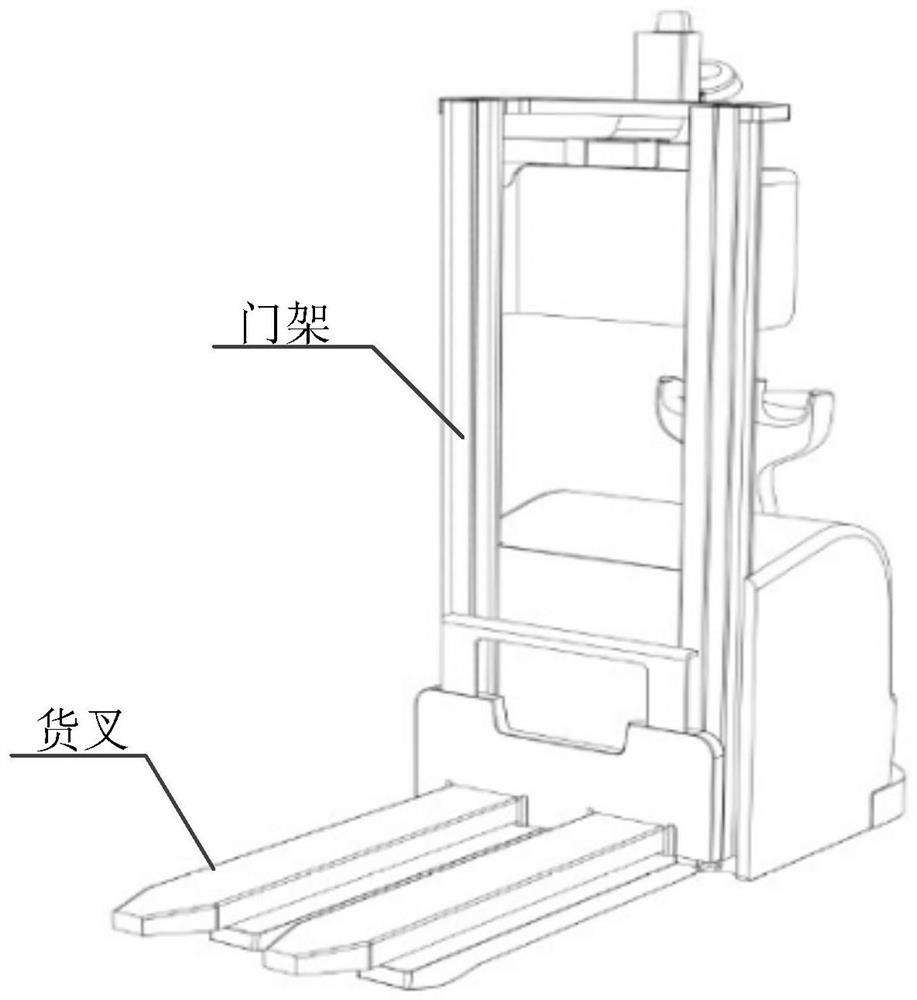

[0140] Figure 4 It shows that the embodiment of the present application provides a warehouse management method. This embodiment can use the situation of accessing items in the storage container in the fixed storage area. This method can be executed by the warehouse management system in Embodiment 1, applicable to In a traditional warehouse environment or a dense storage environment, the method is applied to at least one or more control servers, one or more automatic access systems, multiple autonomous mobile robots, multiple workstations, and multiple temporary storage areas; The automatic access system includes a plurality of high-position racks and a plurality of stackers running on the plurality of high-position racks, the stacker and the autonomous mobile robot are respectively connected to the control server by communication, the Warehouse management methods specifically include:

[0141] Step 402: According to the first order, the control server determines the one or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com