Steel pipe and concrete combined bracket used for roadway junction

A technology of concrete-filled steel tube and combined support, which is applied in tunnels, tunnel lining, earthwork drilling and mining, etc. It can solve the problems of blank application research of steel tube concrete support and low support cost, and achieve high cost performance, low later repair rate, The effect of good compression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

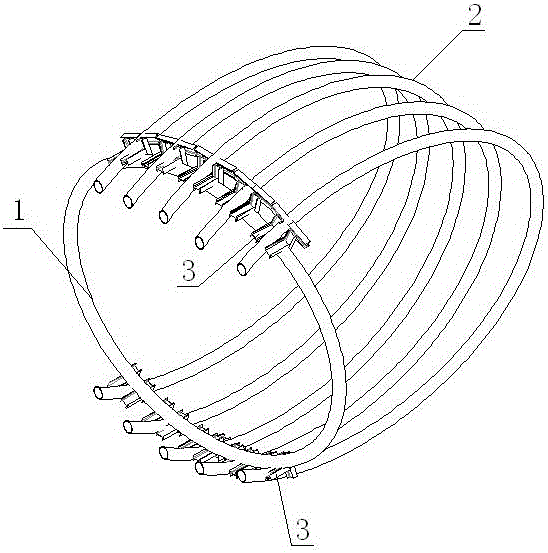

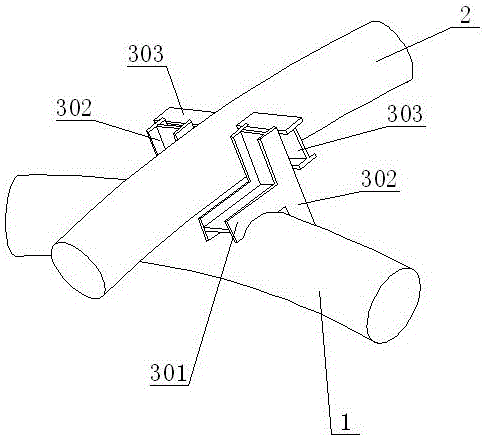

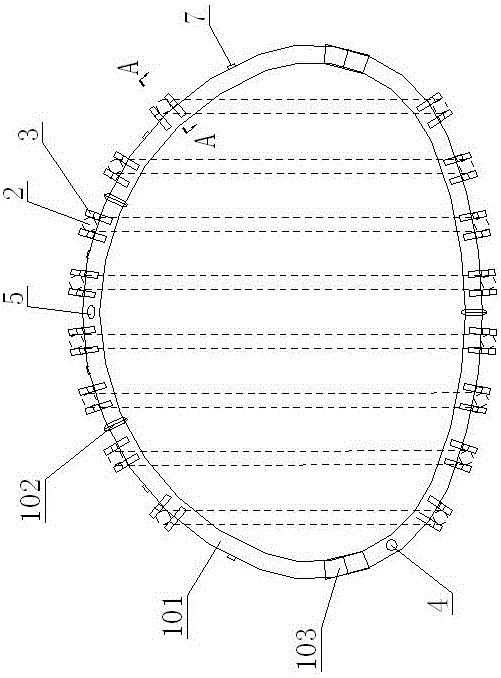

[0042] Such as Figure 1 to Figure 9As shown, the present invention comprises support frame 1, and support frame 1 is the closed structure that connects end to end, is provided with several lap frames 2 at intervals on support frame 1, and lap frame 2 is C shape, and one end of lap frame 2 is positioned at The outer surface of the upper part of the support frame 1 is connected to it through the docking device 3 , and the other end of the splice frame 2 is located on the outer surface of the lower part of the support frame 1 and connected to it through the docking device 3 . The docking device 3 includes a support frame baffle structure and an overlapping frame baffle structure. The support frame baffle structure includes two first baffles 301 welded to the outer sides of the support frame 1 on both sides of the end of the overlapping frame 2, and the two first baffles 301. The distance between a baffle plate 301 is slightly larger than the diameter of the splice frame 2, and t...

Embodiment 2

[0055] Such as Figure 10 ~ Figure 13 As shown, the difference between this embodiment and Embodiment 1 is that it includes a support frame 1, which is a non-closed structure that is not connected from end to end, and several overlapping frames 2 are arranged at intervals on the support frame 1. 2 is n-shaped, one end of the splicing frame 2 is located on the outer surface of the upper part of the support frame 1 and connected to it through the docking device 3, and the other end of the splicing frame 2 is fixed on the roadway floor. The docking device 3 is an insertion sleeve 3001 welded on the upper part of the support frame 1 , and one end of the splicing frame 2 is inserted into the insertion sleeve 3001 to be plugged therewith. Both sides of the socket sleeve 3001 are provided with wing plates 3002 , and the wing plates 3002 are welded on the socket sleeve 3001 and the support frame 1 . Both the support frame 1 and the splice frame 2 are provided with a grouting port 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com