Construction method for plugging construction joint of frame beam

A construction method and technology for frame beams, applied in joists, girders, truss beams, etc., can solve the problems of frame beam concrete running, cement slurry seepage, hemp surface, etc., to avoid concrete slag inclusion, easy installation and dismantling, Good joint quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

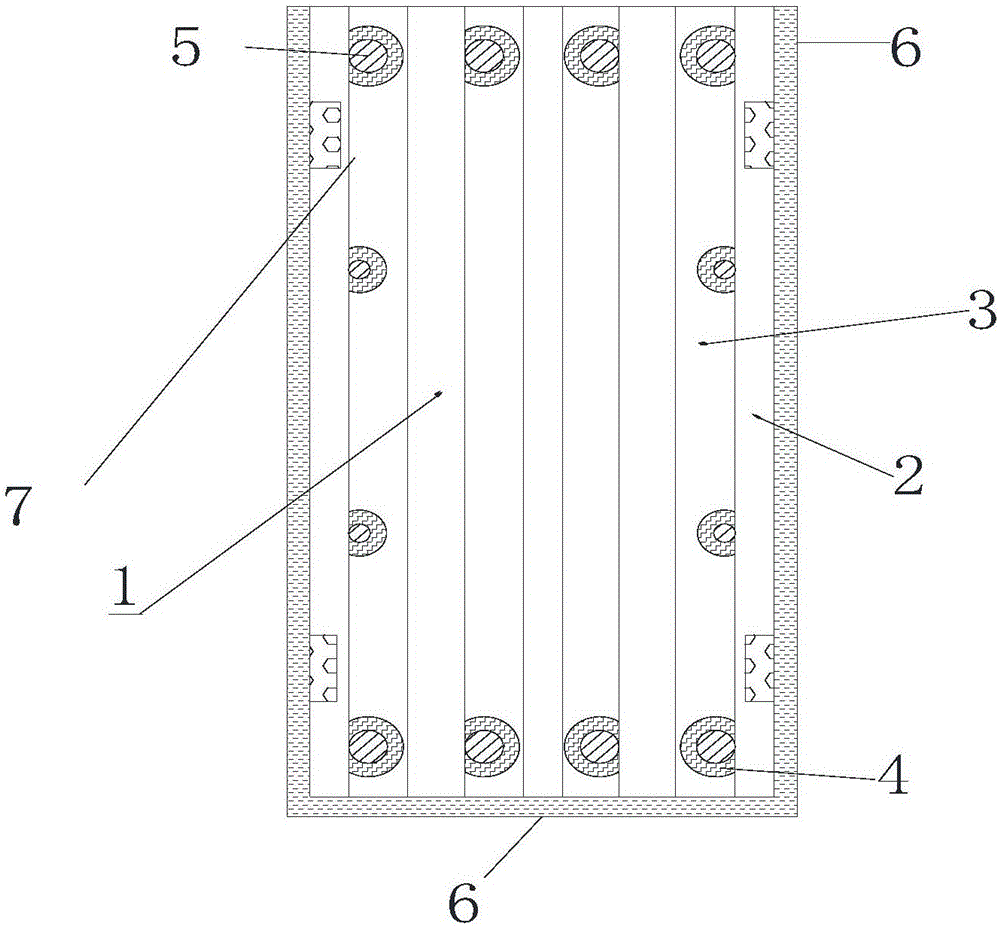

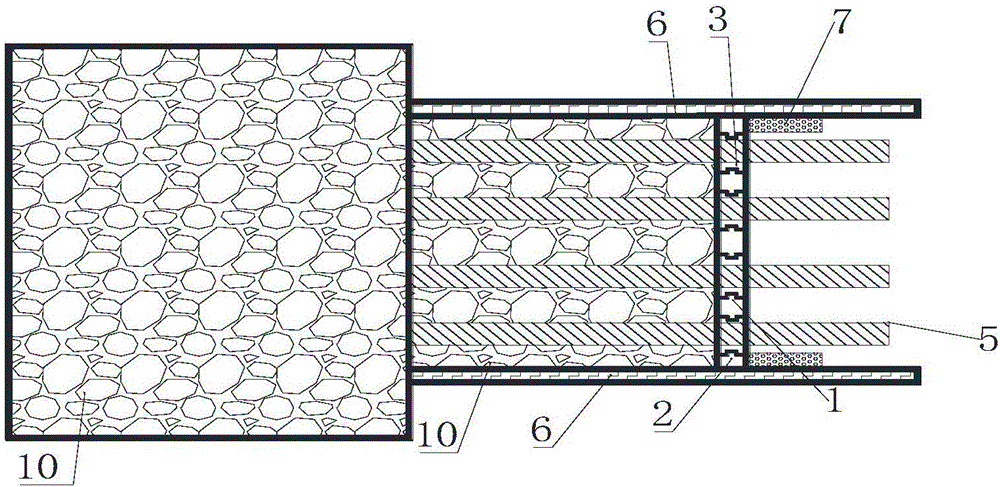

[0050] (1) U-shaped frame beam template 6 is installed at the construction joint position;

[0051](2) Positioning stoppers 7 are respectively installed up and down on the insides of the front ends of the two vertical plates of the frame beam formwork;

[0052] (3) Install the full-length longitudinal reinforcement 5 of multiple beams in the frame beam formwork;

[0053] (4) Insert the side of the plugging steel formwork 3 with a full-length groove along the frame beam longitudinal reinforcement 5 direction between every two adjacent longitudinal reinforcements 5, and the full-length grooves are respectively opened along the vertical direction. In the middle of the left wall and the right wall of each blocking steel formwork 3, there is a C-shaped opening corresponding to the position of the longitudinal reinforcement 5 on the left wall or the right wall of the blocking steel formwork 3, and the opening A rubber ring 4 is installed inside, and the inner ring diameter of the r...

Embodiment 2

[0062] (1) U-shaped frame beam template 6 is installed at the construction joint position;

[0063] (2) Positioning stoppers 7 are respectively installed up and down on the insides of the front ends of the two vertical plates of the frame beam formwork;

[0064] (3) Install the full-length longitudinal reinforcement 5 of multiple beams in the frame beam formwork;

[0065] (4) Insert the side of the plugging steel formwork 3 with a full-length groove along the frame beam longitudinal reinforcement 5 direction between every two adjacent longitudinal reinforcements 5, and the full-length grooves are respectively opened along the vertical direction. In the middle of the left wall and the right wall of each blocking steel formwork 3, there is a C-shaped opening corresponding to the position of the longitudinal reinforcement 5 on the left wall or the right wall of the blocking steel formwork 3, and the opening A rubber ring 4 is installed inside, and the diameter of the inner ring ...

Embodiment 3

[0074] (1) U-shaped frame beam template 6 is installed at the construction joint position;

[0075] (2) Positioning stoppers 7 are respectively installed up and down on the insides of the front ends of the two vertical plates of the frame beam formwork;

[0076] (3) Install the full-length longitudinal reinforcement 5 of multiple beams in the frame beam formwork;

[0077] (4) Insert the side of the plugging steel formwork 3 with a full-length groove along the frame beam longitudinal reinforcement 5 direction between every two adjacent longitudinal reinforcements 5, and the full-length grooves are respectively opened along the vertical direction. In the middle of the left wall and the right wall of each blocking steel formwork 3, there is a C-shaped opening corresponding to the position of the longitudinal reinforcement 5 on the left wall or the right wall of the blocking steel formwork 3, and the opening A rubber ring 4 is installed inside, and the inner ring diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com