Efficient welding method for one side welding both-side formation

A single-sided welding double-sided, welding method technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of small angle welding difficult to reach, low efficiency of manual arc welding, welding tools and pipe butt , to achieve the effect of reducing welding wettability, excellent arc starting characteristics, and shortening the training period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

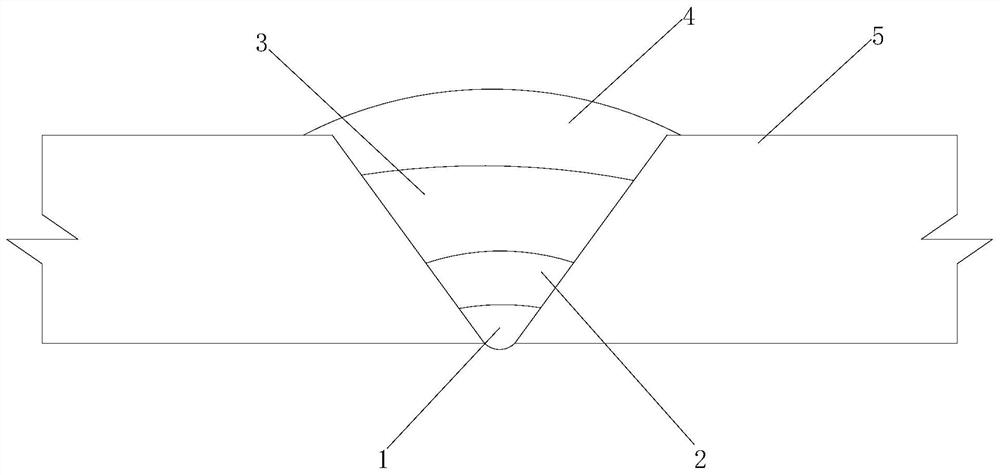

[0031] A welding method for high-efficiency single-sided welding and double-sided molding according to an embodiment of the present invention, such as figure 1 As shown, the specific steps are as follows:

[0032] Step S1, blanking the workpiece according to the drawing requirements;

[0033] Step S2, grinding and assembling the blanked workpiece according to the drawing to form the workpiece 5 to be welded;

[0034] Step S3, start the digital pulse arc welding machine, select the pulse arc mode on the digital pulse arc welding machine, adjust the current to 60-100A, and complete the welding of the root bead 1 of the workpiece to be welded. The thickness of the root bead 1 is 4-8mm , the width of the root bead 1 is 4-8mm, and this layer of bead is mainly used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com