Welding method for molded surface of invar alloy composite material forming mold

A composite material, Invar technology, applied in welding equipment, welding medium, welding equipment and other directions, can solve the problems of low welding efficiency, long manufacturing cycle, restricting production capacity, etc., to improve welding efficiency, shorten manufacturing cycle, prevent Effects of air leakage and slag inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The purpose of the present invention is to explore a new welding method for Invar alloy (INVAR) thick plate δ20mm or more, improve the welding efficiency of the Invar alloy (INVAR) composite material forming mold surface, greatly shorten the manufacturing cycle of the mold surface, and prevent the welding of the mold surface. The phenomenon of air leakage and slag inclusion occurs.

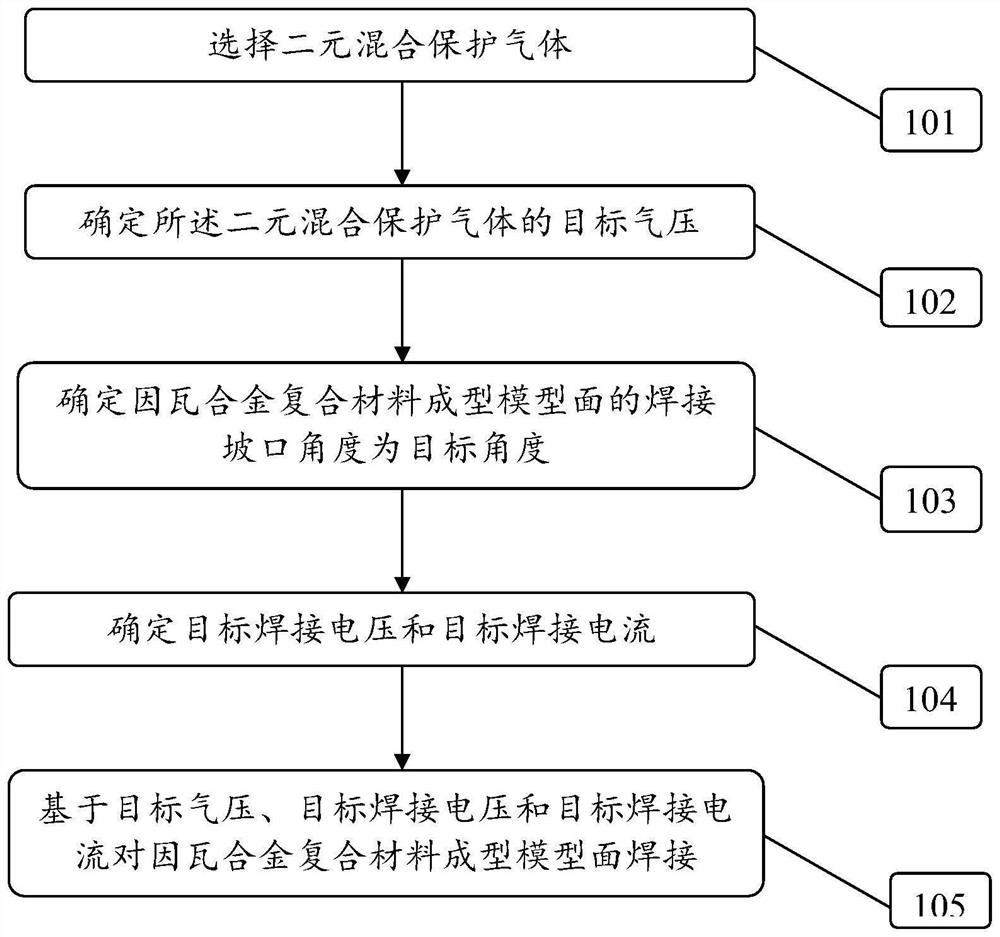

[0024] It should be noted that the main content of the invention is to change the welding method: carry out systematic process tests by replacing argon arc welding (TIG welding) with gas shielded welding (MIG welding), and explore a new welding process method for INVAR steel.

[0025] To achieve the above object, the present invention provides the following technical solutions:

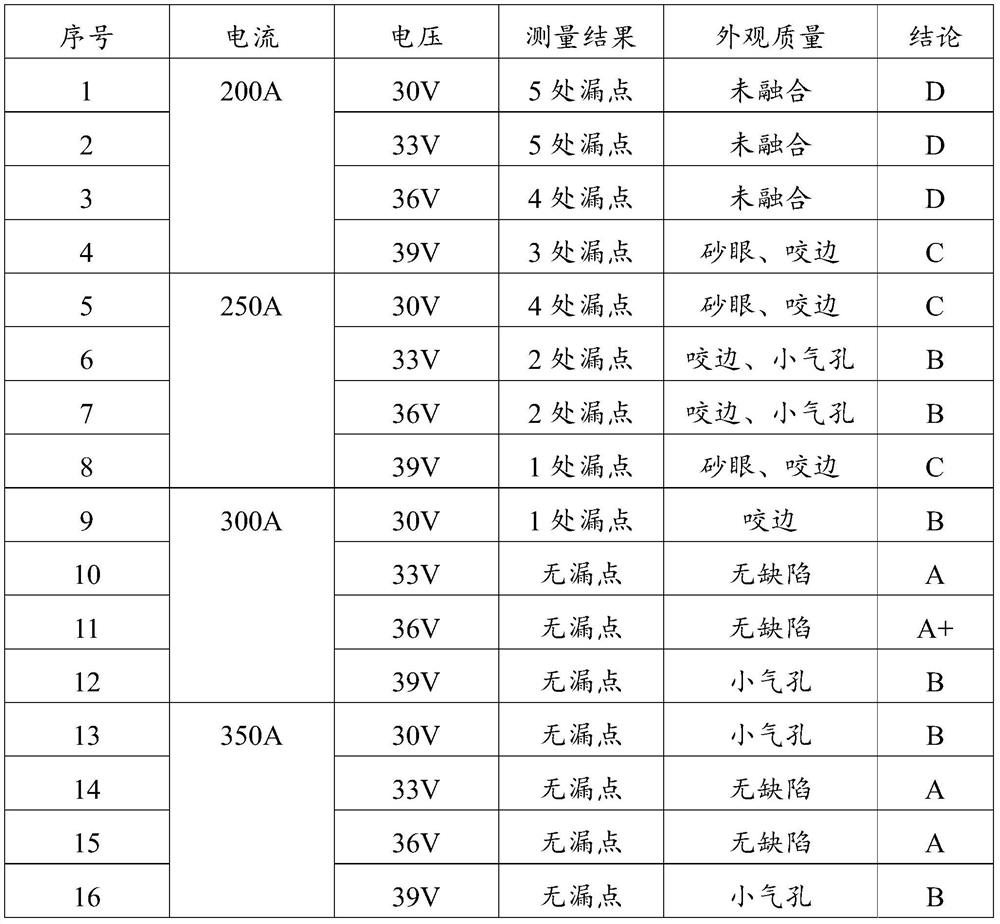

[0026] Conduct welding tests to determine relevant welding parameters

[0027] Change the welding method: gas shielded welding (MIG welding) instead of argon arc welding (TIG welding)

[0028] 1. Selection of pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com