A simulation test method for mining failure of the bottom floor of mine working face

A technology of simulation test and bottom plate mining, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of water inrush on the bottom plate, achieve convenient operation, solve the problem of mining damage to the bottom plate water inrush, and simple test methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

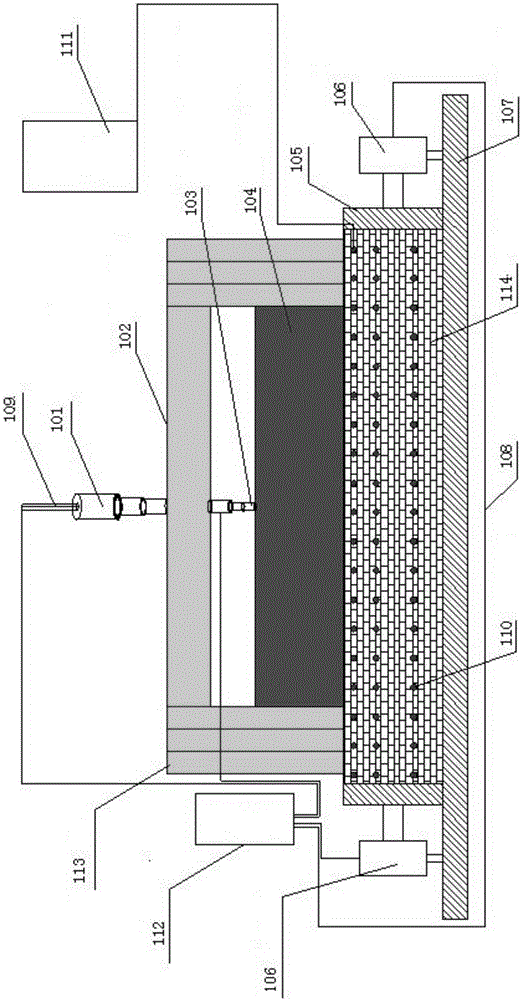

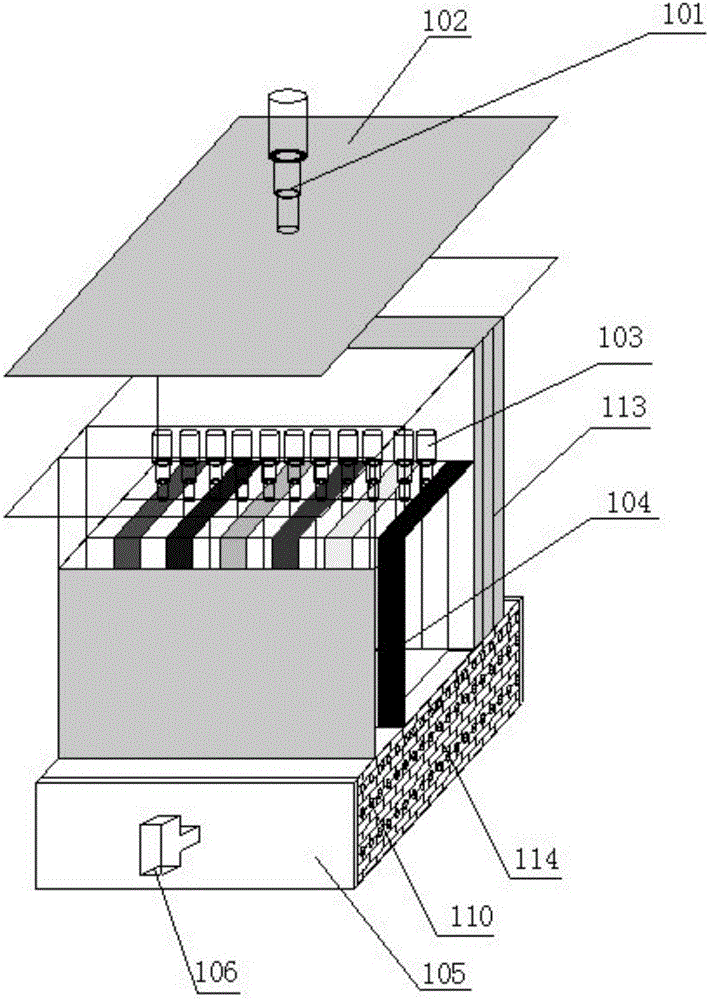

[0017] This embodiment adopts the mine working face floor mining damage simulation test device to carry out the simulation test on the mine working face floor mining damage, including the preparation of the test rock mass 114, the mine working face floor mining floor damage simulation test test and the mine working face mining damage simulation test. There are three steps in the analysis of the failure mechanism of the movable floor, and the specific process is as follows:

[0018] (1), the preparation of test rock mass 114: test rock mass 114 has two kinds, and a kind of is the mine working face floor rock that gathers when mine working face roadway excavation, and the plane of mine working face floor rock will meet the present situation during preparation. There are standards stipulated in the rock mechanics test in the technology; the other is the working face floor prepared from the simulated material similar to the rock of the mine working face floor, and the ratio of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com