Mining failure simulation test device for mine working face floor

A simulation test and floor mining technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as water inrush on the floor, and achieve the effects of scientific principle, convenient operation, and accurate monitoring data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

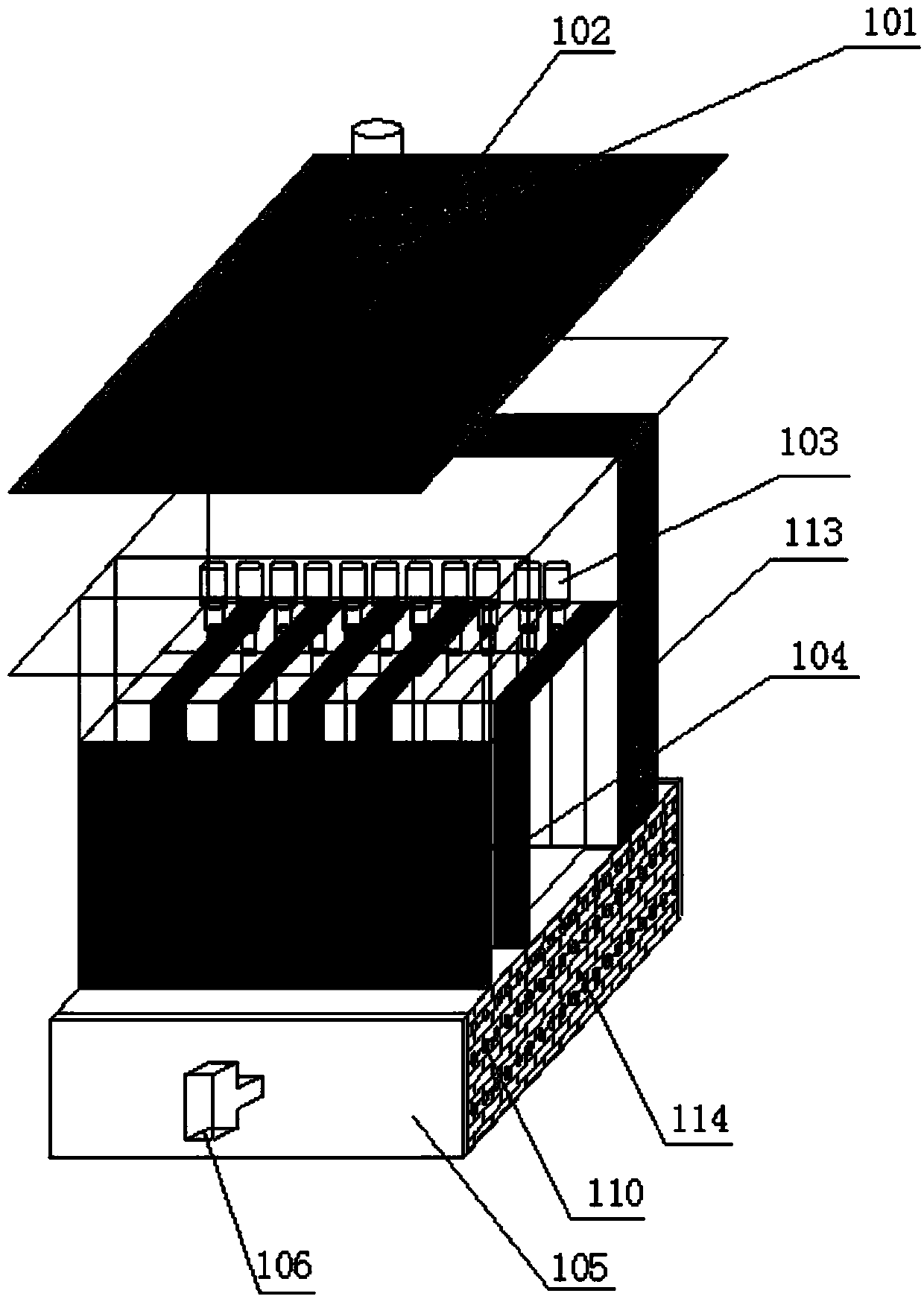

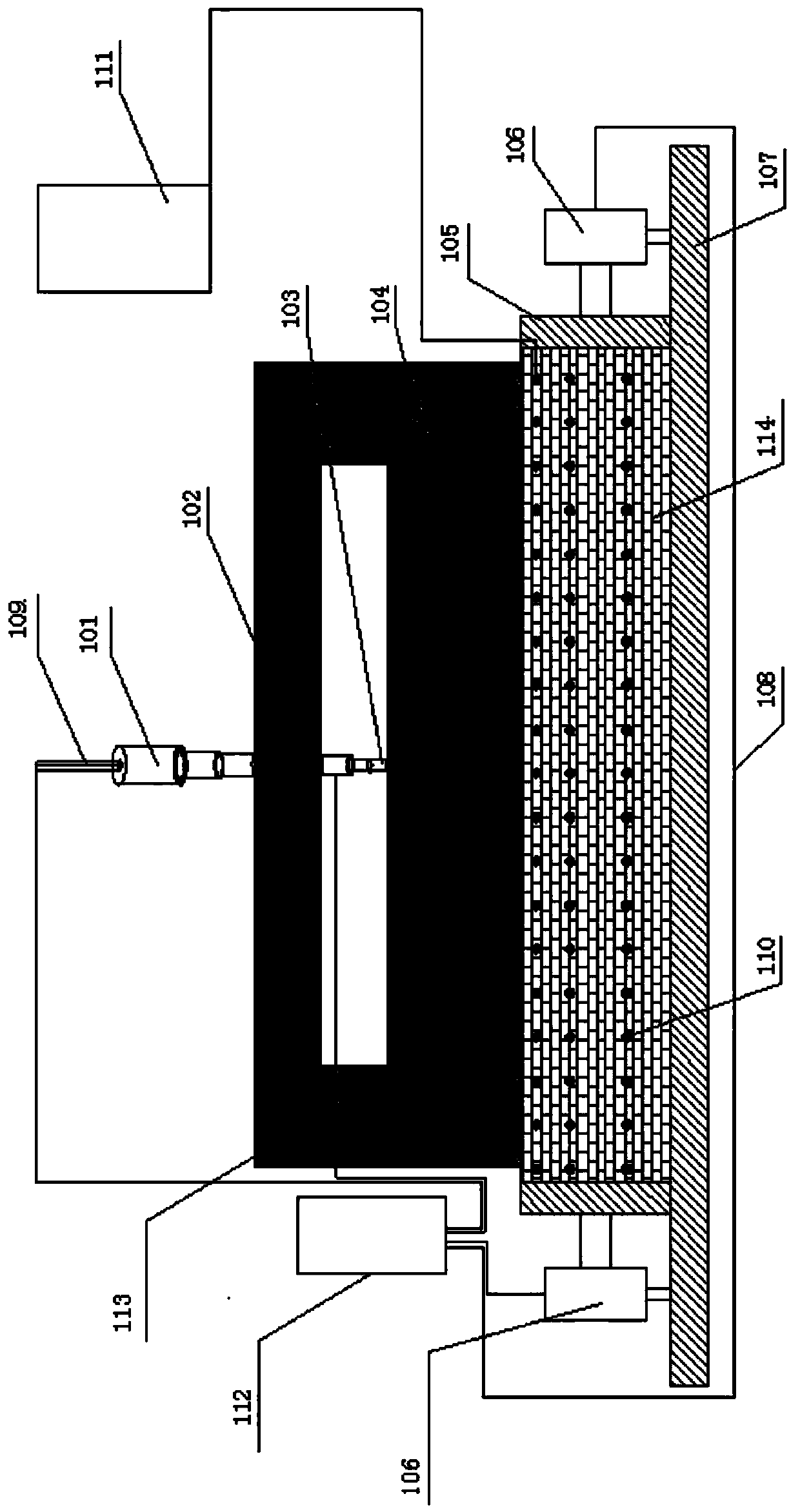

[0017]The mining failure simulation test device for the bottom floor of the mine working face involved in this embodiment includes a main hydraulic servo loader 101, a top loading body 102, a hydraulic servo unloading loader 103, an unloading loading plate 104, a side fixing plate 105, and a side loading fixing 106, platform base 107, hydraulic pipeline 108, top hydraulic pipeline 109, stress monitoring point 110, stress acquisition system 111, hydraulic servo control system 112, removable side 113 and test rock mass 114; The side loading fixture 106 is used for the symmetrical fixing system to simulate the loading effect of the lateral structural stress on the formation; the side loading fixture 106 is fixedly connected with the side fixing plate 105. The test rock mass 114 is contacted and loaded to the fixed plate 105; the side loading fixture 106 fixes the test rock mass 114 on the platform base 107 through the lateral fixed plate 105; There are stress monitoring points 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com