Method for draining gas by heating coal bed through drilling

A technology of heating method and mining method, which is applied in the directions of gas discharge, earth-moving drilling, mining fluid, etc., can solve the problems of inability to carry out the seepage phase, the effect of coalbed methane mining is weak, etc., and achieve effective and rapid gas drainage, increase in cracks, increase The effect of coal fissures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

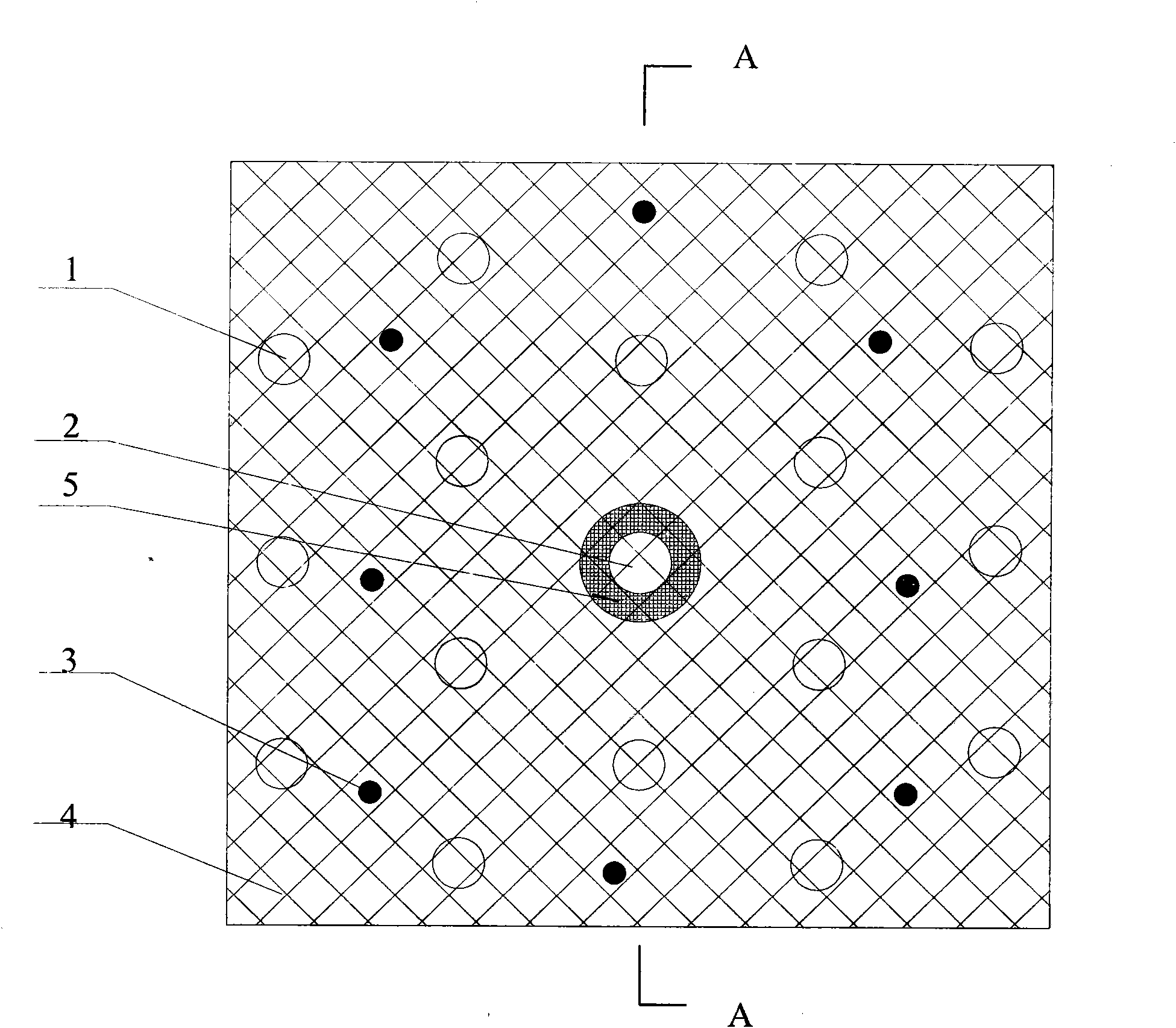

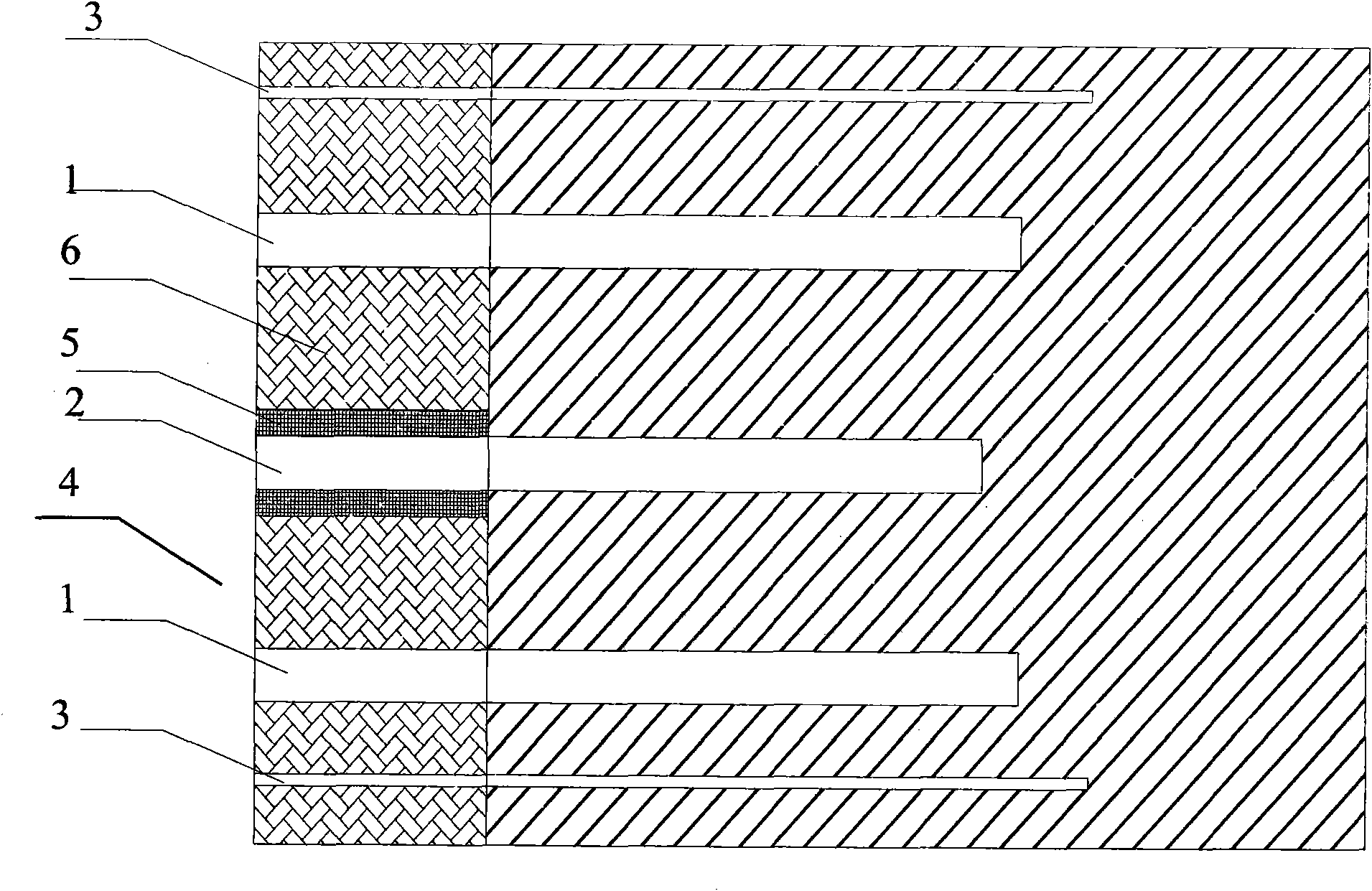

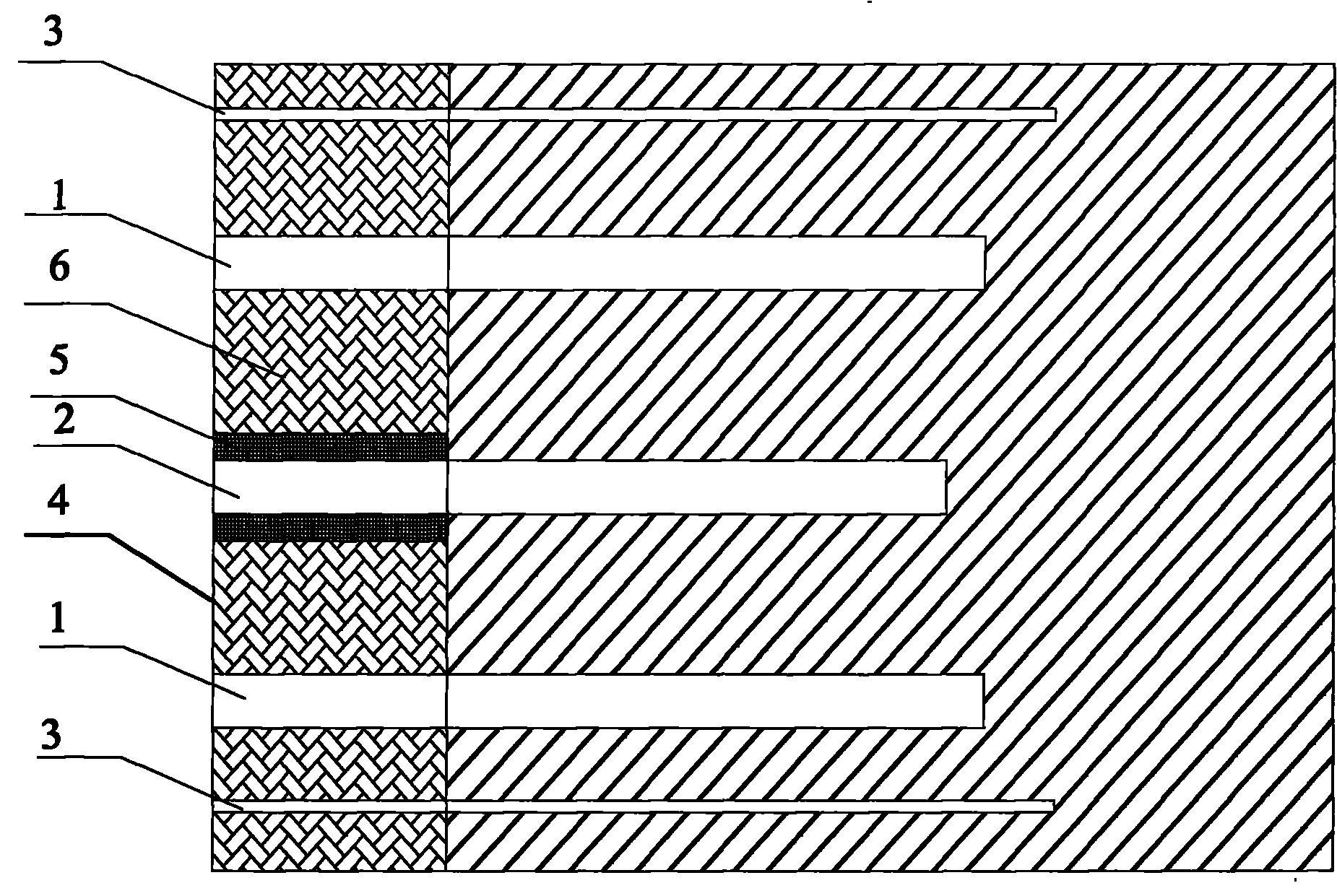

[0033] figure 1 For the coal seam to be extracted, the gas drainage borehole (1) is firstly drilled in the coal seam, and the appropriate drainage borehole is selected as the heat source hole (2), ensuring that the heat source hole (2) has a radius of 0.5m on the More than 6 drainage boreholes, then reaming the heat source hole, the reaming distance is to pass through the protective seam coal seam (6), after the drilling is done, lay anchor nets (4) on the coal seam surface and use anchor rods (3 ) reinforcement.

[0034] Put the heating equipment of the coal seam into the heat source hole (2), and fix the heating equipment with the heat insulating material (5) at the first 1 / 3 of the hole to ensure that the coal seam (6) of the protective layer is not heated. The coefficient selects whether to carry out enhanced drainage measures on the coal seam to increase the air permeability of the coal seam.

[0035] After the equipment is connected, the heating equipment is operated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com