Combined rock cross-cut coal uncovering method

It is a combination technology for uncovering coal at Shimen, which is applied in earthwork drilling, surface mining, underground mining, etc. It can solve problems such as increasing the difficulty of sealing holes and operating risks, reducing the overall strength of coal and rock, and destroying the integrity of coal bodies. Achieve the effects of shortening the gas pre-pumping time, increasing the effective range of influence, and reducing the amount of outburst elimination works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

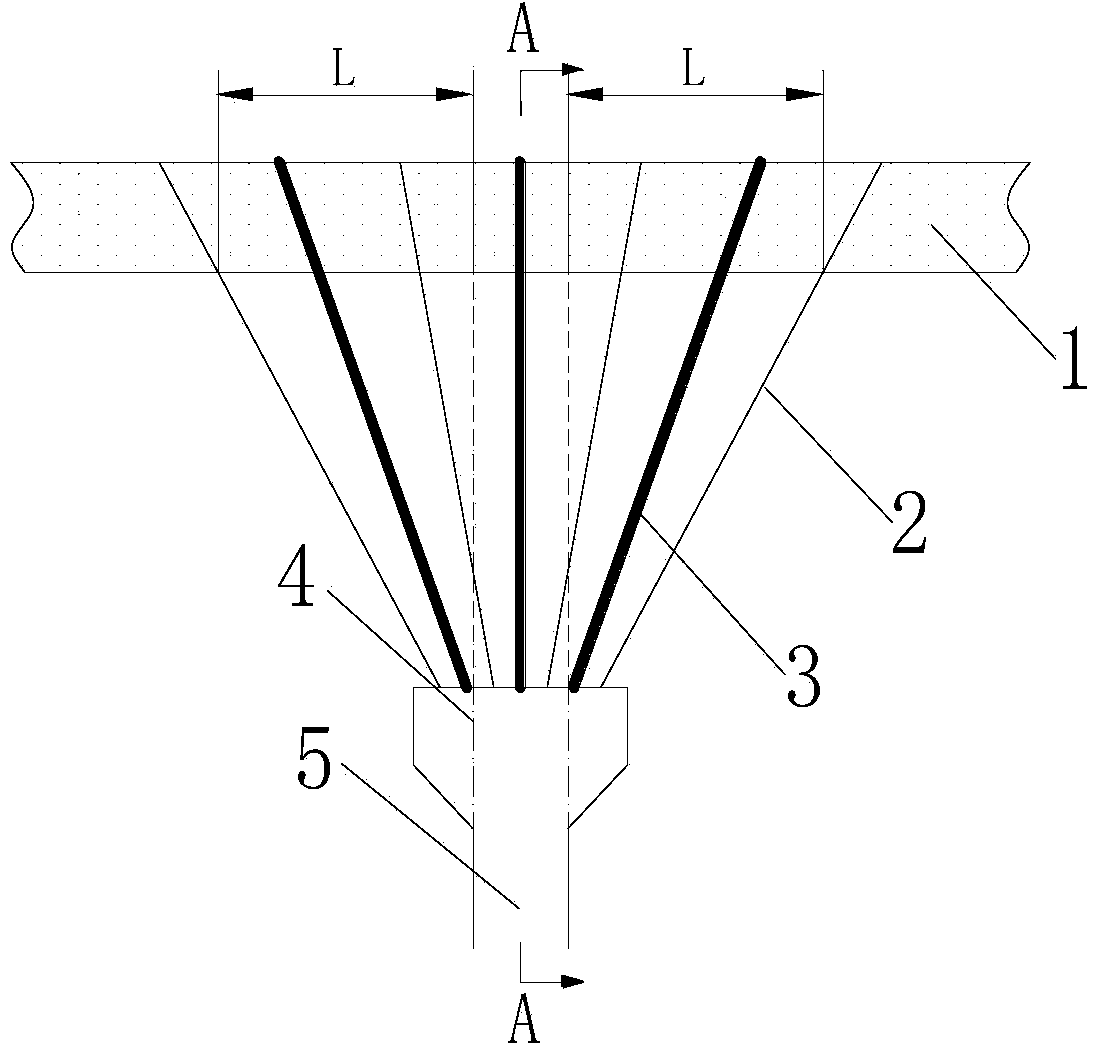

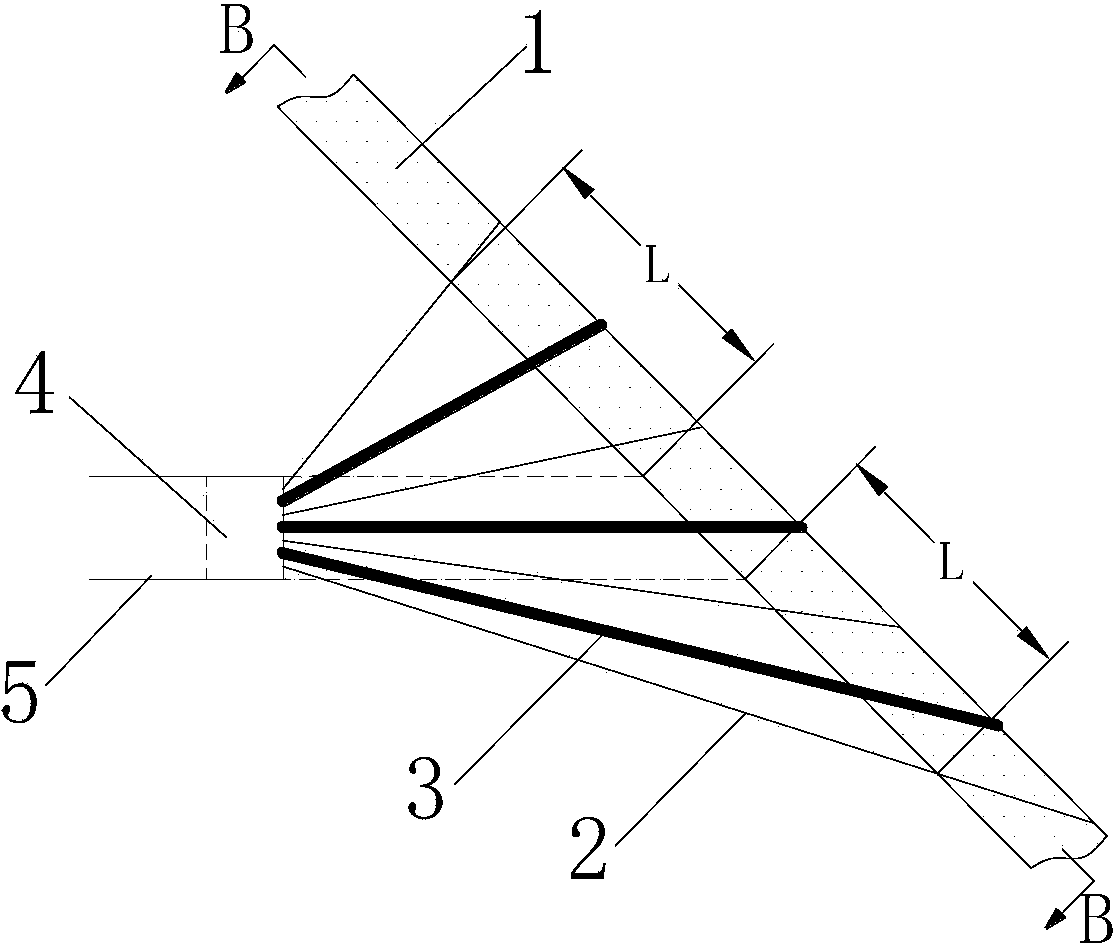

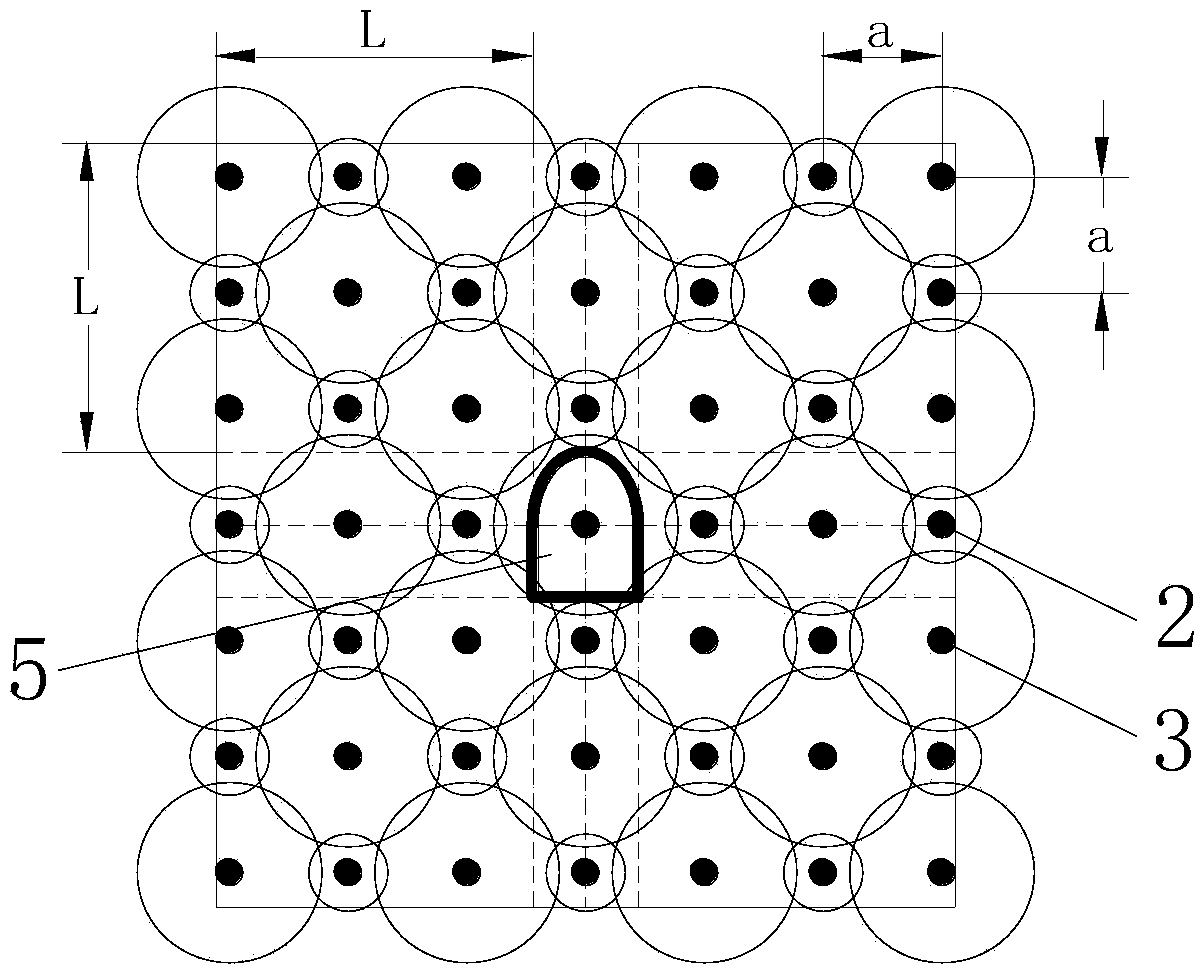

[0017] Such as figure 1 , figure 2 and image 3 As shown, a combined method for uncovering coal at Shimen of the present invention includes the following steps: Shimen 5 implements exploration and excavation while digging according to conventional methods, and explores parameters such as the azimuth, inclination and thickness of the coal seam according to the geological hole data of construction, and uncovers the coal for Shimen. Lay the foundation for coal work; when the vertical distance between Shimen 5 head-on and coal seam 1 is 10m, stop the excavation, and construct drilling site 4 head-on at Shimen 5. The size of drilling site 4 depends on the type of drilling rig. Transfer to drilling site 4, according to image 3 As shown, a plurality of drill holes forming a network are constructed alternately from the drill field 4 to the coal seam 1 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com