A kind of gently inclined super thick coal seam Shimen coal excavation method

A technology for uncovering coal in extra-thick coal seams and Shimen, which is applied in earthwork drilling, special mining, gas discharge, etc., can solve problems such as safety hazards in coal removal, prolongation of coal removal cycle, drill stuck, etc., to reduce the difficulty of operation, safe and fast The effect of uncovering coal and eliminating blank belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

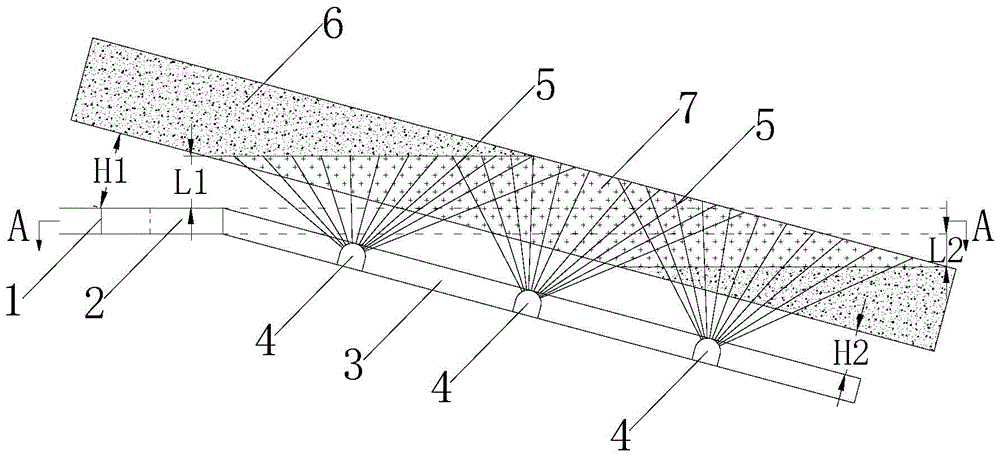

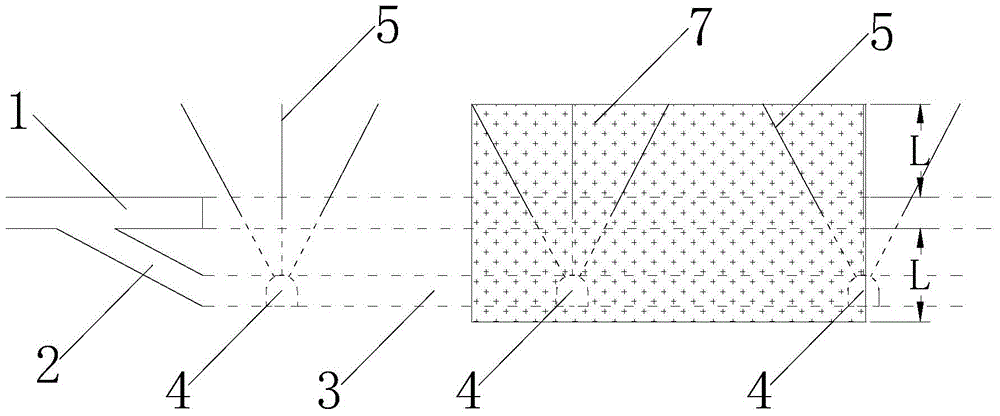

[0020] Such as figure 1 and figure 2 As shown, a method for uncovering coal in a gently inclined extra-thick coal seam stone gate of the present invention includes the following steps: the stone gate 1 implements exploration and digging according to the conventional method, and finds out the basic parameters such as the orientation, inclination angle and thickness of the coal seam according to the geological hole situation. When Shimen 1 is excavated to the vertical distance H1 of 12m from coal seam 6, stop the excavation and excavate a horizontal oblique Shimen 2 on the right side of Shimen 1. Depending on the geological conditions), Xieshimen 2 was excavated while exploring according to the conventional method. When the inclined stone gate 2 is excavated to the vertical distance H2 of 7m from the coal seam 6, the excavation is stopped, and a floo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com