Mine MWD exploration system and measurement method thereof

A technology of inclination-while-drilling and exploration systems, applied in seismology and construction for well logging records, can solve problems such as cost increase, seismic wave signal weakening, information acquisition lag, etc., to reduce time and engineering quantity, signal The effect of improving the signal-to-noise ratio and improving the prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

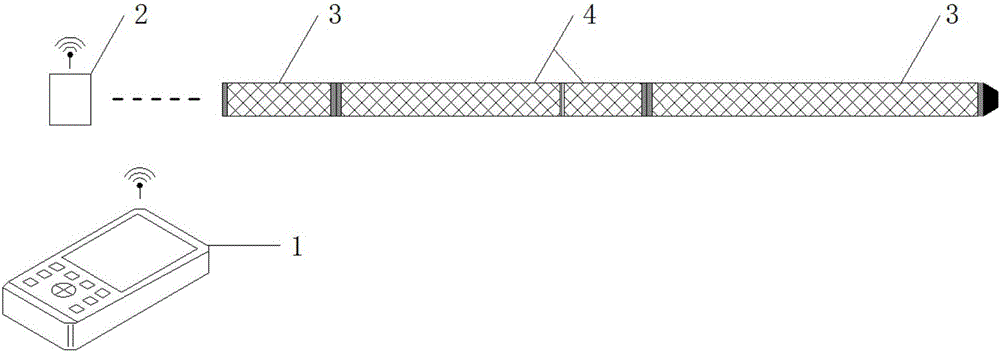

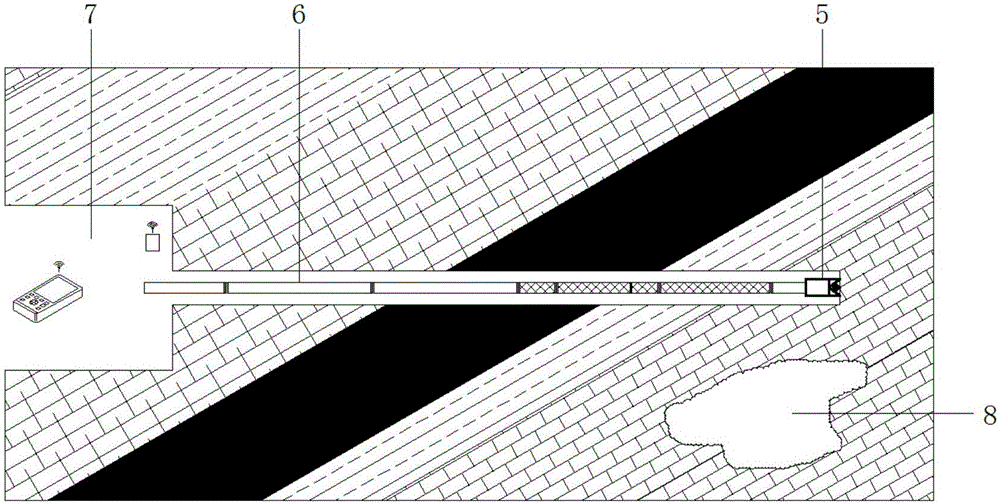

[0041] Such as figure 1 As shown, the mine inclinometer-while-drilling exploration system of this embodiment includes a measurement module, a communication device 2 and a hand-held terminal 1 . The measurement module is installed behind the drill bit 5 and is propelled by the drill rod 6, and directly uses the vibration generated by the drill bit 5 breaking rock as a seismic source.

[0042] The measuring module includes a measuring probe 4 and non-magnetic rods 3 installed at the front and rear ends of the measuring probe 4 . The measuring probe 4 is used for signal acquisition in the hole and plays the role of transmission and water passage at the same time. The non-magnetic rod 3 is used to isolate the magnetic interference generated by the drill pipe 6 on the measurement probe 4, and also has the function of transmission and water passage. The communication device 2 is installed in the drilling field outside the hole to realize the communication between the measuring prob...

Embodiment 2

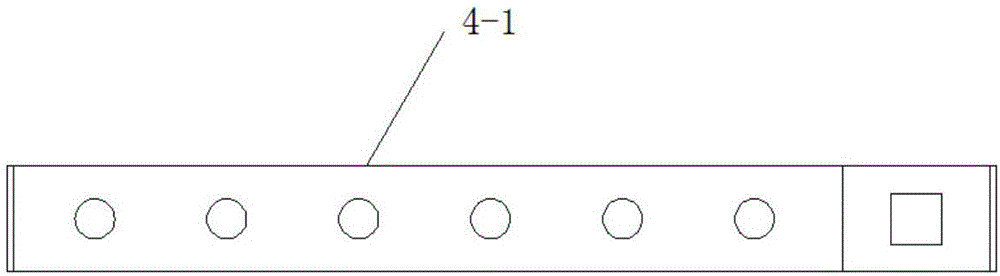

[0045] Such as figure 2 As shown, the seismic measurement module 4-1 adopts two sets of geophone groups, a three-component geophone group and a small array geophone group. Among them, the three-component geophone group is used to detect vibration signals in real time, and controls the on and off status of the inclinometer module and the small array geophone group through the threshold and time, and the small array geophone group is arranged with 6 geophones, and the track spacing is 0.05. -0.3m, as the measurement of discontinuous dynamic signals, observe the seismic direct wave, reflected wave, diffracted wave and other signals excited by the rock breaking of the drill bit 5 and propagated through the drill bit 5 / drill pipe 6 and the surrounding rock of the borehole.

[0046] by Figure 3-Figure 7 As an example to illustrate a kind of applicable measurement-while-drilling method based on the composition, characteristics and drilling construction of the system of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com