Drill site tubular pile automatic discharging device

An automatic discharge and string technology, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of potential safety hazards, low operating efficiency, heavy workload of operators, etc., to achieve strong applicability, convenient horizontal transportation, The effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

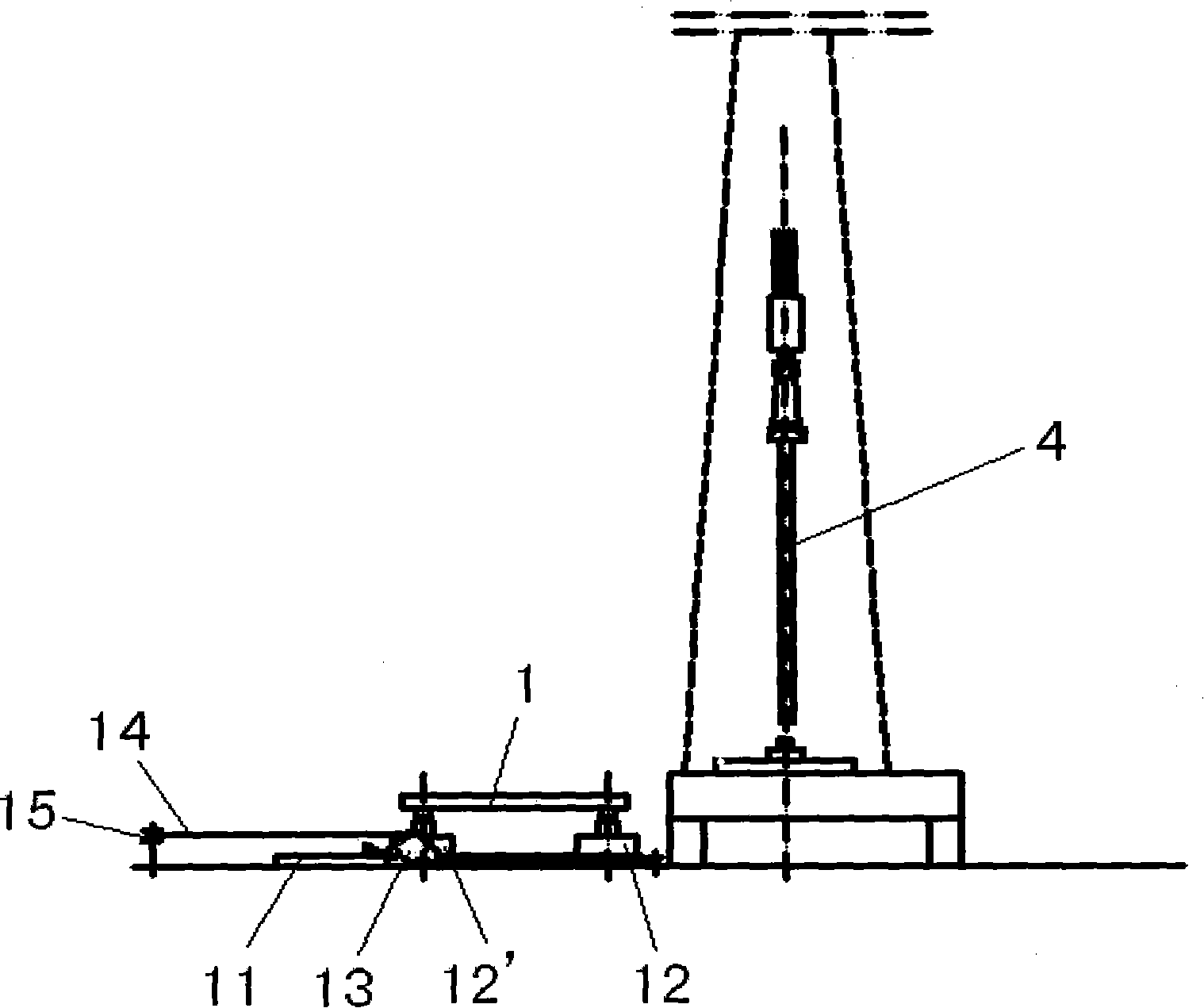

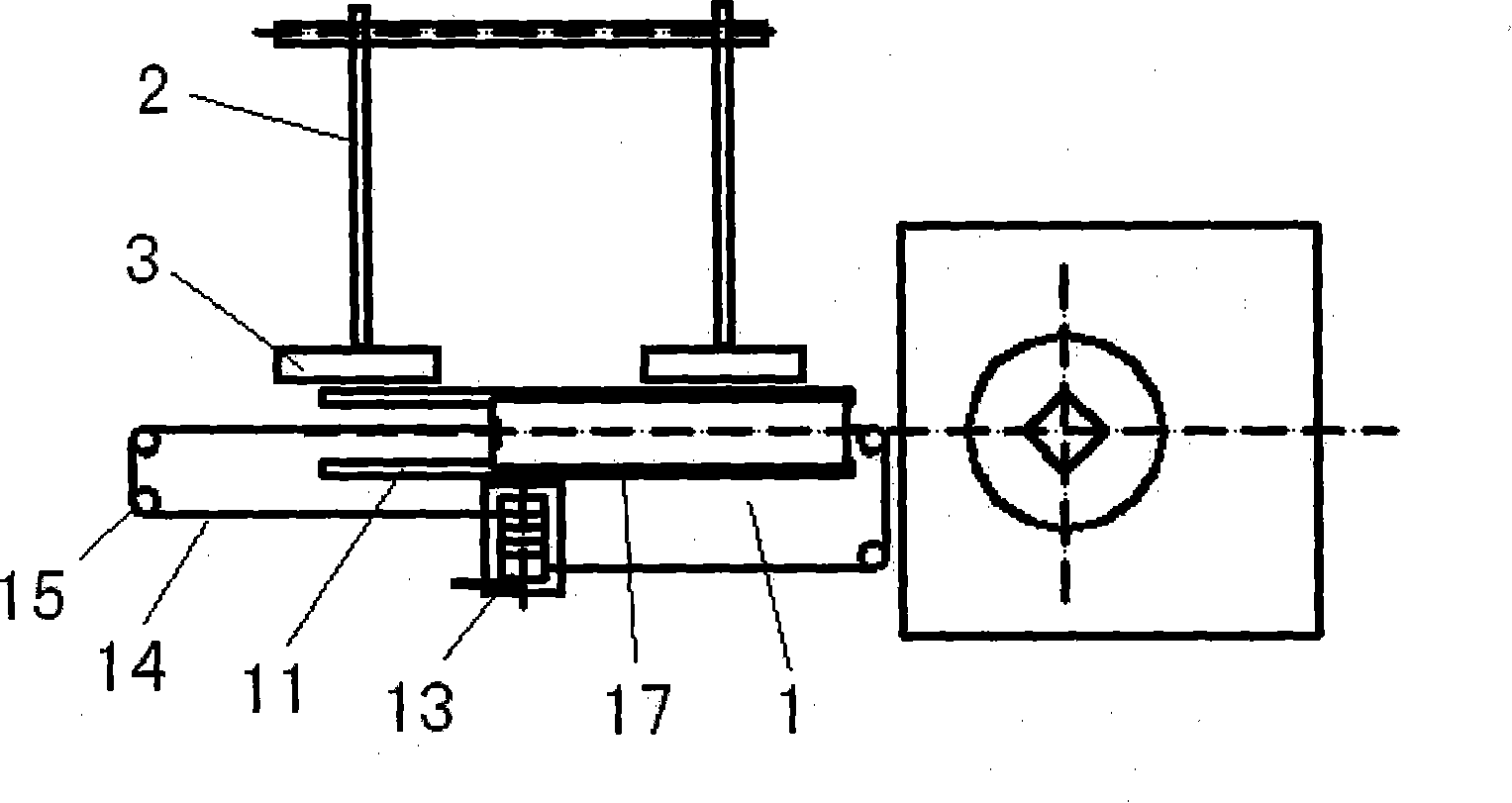

[0024] like figure 2 , image 3 As shown, the present invention includes a mobile lifting device 1 and a multi-layer pipe rack 2, and may also include a lifting pipe bridge 3. The mobile lifting device 1 includes a track 11, on which two lifting cylinders 12, 12' are slidably arranged, and a pneumatic winch 13 is set on one side of the track 11, and the pneumatic winch 13 passes a wire rope 14 and a plurality of pulleys 15 A dragging device for controlling the movement of the two lift cylinders 12, 12' is formed.

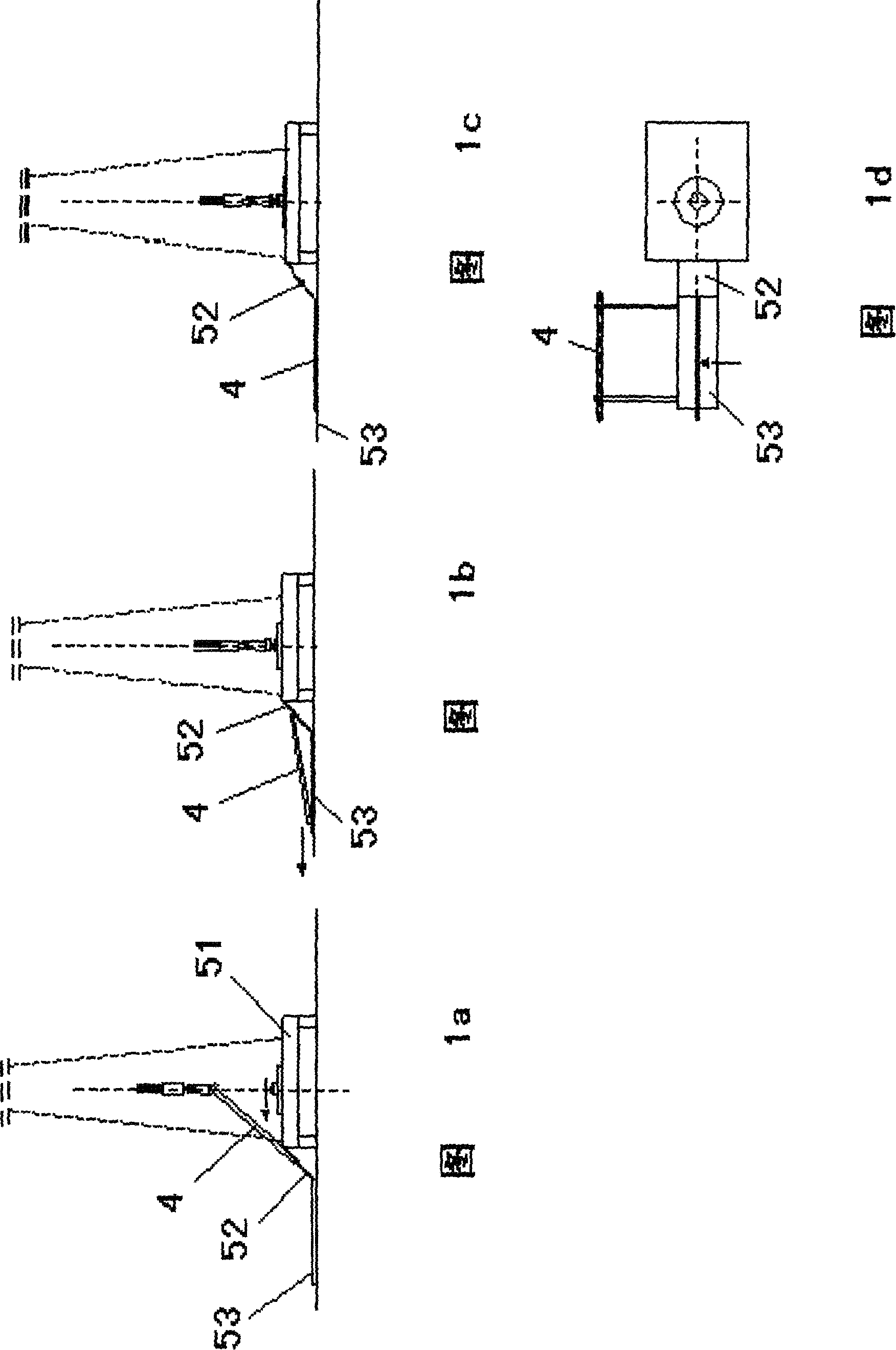

[0025] like Figure 4 , Figure 5 , Image 6 As shown, the tops of the plungers of the two lifting cylinders 12, 12' are connected to a pair of baffle plates forming the slideway 17 through a pivot 16, and a spring return cylinder 18 is respectively installed between the two baffle plates of the slideway 17 and the plungers. , the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com