Construction method of hoisting and positioning device modified by corrugated steel web asynchronous hanging basket

A corrugated steel web and construction method technology, which is applied in the erection/assembly of bridges, buildings, bridge construction and other directions, can solve the problems such as the long tower crane arm cannot be constructed, the influence of wind force is large, and the installation and positioning are complicated, so as to achieve low construction cost, The effect of small wind influence and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

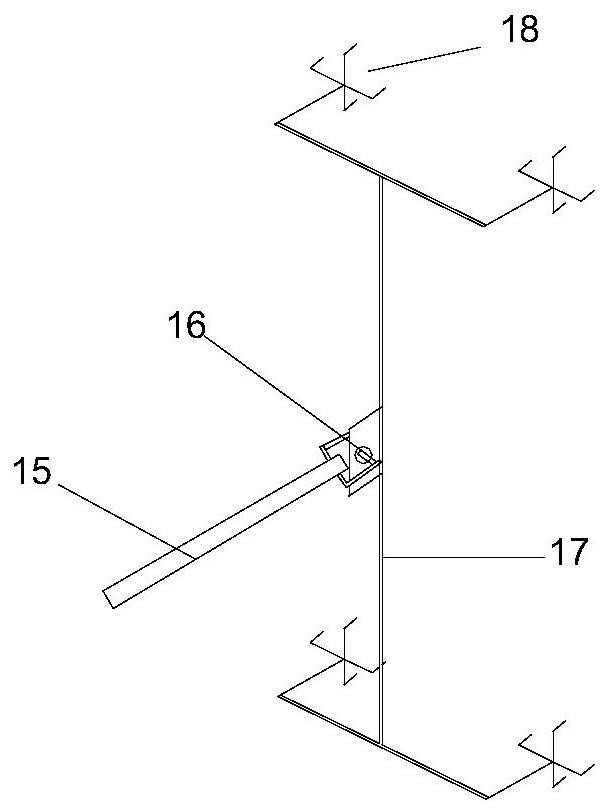

[0031] The asynchronous hanging basket of the corrugated steel web is refitted with a hoisting and positioning device, and the corrugated steel web is constructed using an asynchronous hanging basket refitted lifting device. The board slides from the rear end of the longitudinal track beam to the front end through the slide rail trolley and then lowers down. During the lowering installation process of the corrugated steel web, a guide protection device is used for auxiliary installation to prevent swinging and deflection due to the influence of wind force during lowering and assembling. The installation and positioning operation is simple. It has good economic and technical benefits.

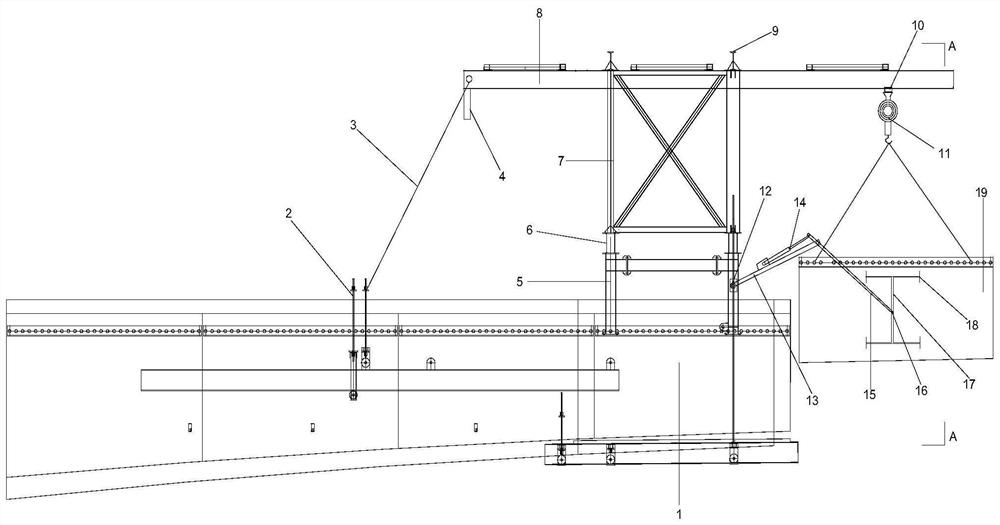

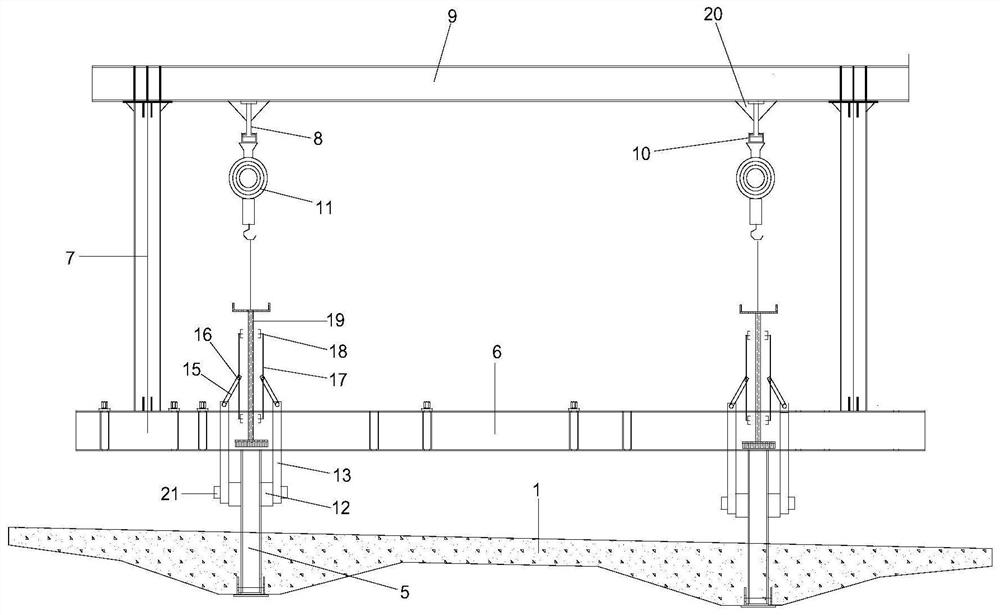

[0032] Such as Figure 1-2 As shown, the corrugated steel web asynchronous hanging basket modification hoisting and positioning device includes the nth section box girder 1, screw rod 2, steel wire rope 3, limit plate 4, hanging basket column 5, hanging basket crossbeam 6, steel column 7, Longi...

Embodiment 2

[0040] The construction method for modifying the hoisting and positioning device of the corrugated steel web asynchronous hanging basket includes the following steps:

[0041] (1) Hanging basket modification: During the construction process of the n-section box girder 1, the screw rod 2 is set in advance, the upper part of the hanging basket is removed, the hanging basket column 5 and the hanging basket crossbeam 6 are reinforced, and the hanging basket column 5 is pre-installed. Drill holes for equipment installation.

[0042] (2) Welding of the main frame: the steel column 7, the longitudinal track beam 8, and the main beam 9 are prepared in advance in the factory according to the design size, and after they are transported to the site, the steel column 7 and the main beam 9 are welded on the ground Form a film frame, hoist the whole film frame to a predetermined position on the refitted asynchronous hanging basket, weld the steel column 7 and the hanging basket beam 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com