Three-dimensional spraying system for large workpieces

A large workpiece, three-dimensional technology, applied in the field of spraying systems, can solve the problems of difficult automatic spraying, poor uniformity, and low coating efficiency, and achieve the effect of meeting the requirements of uniform spraying, meeting the requirements of spraying, and improving the efficiency of spraying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

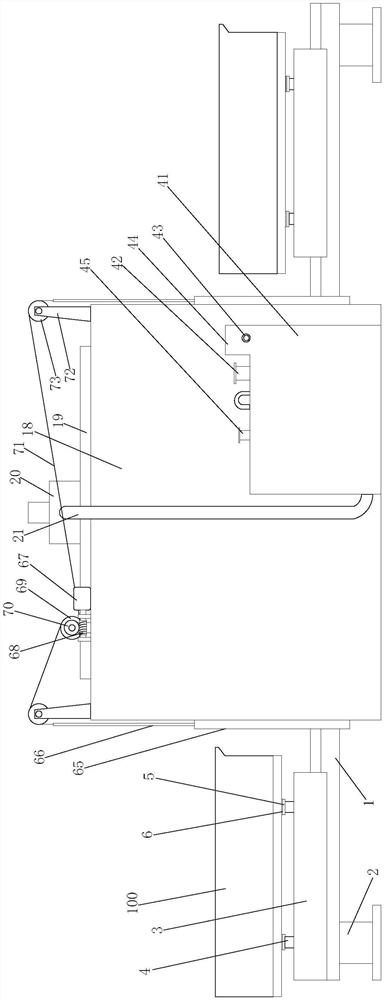

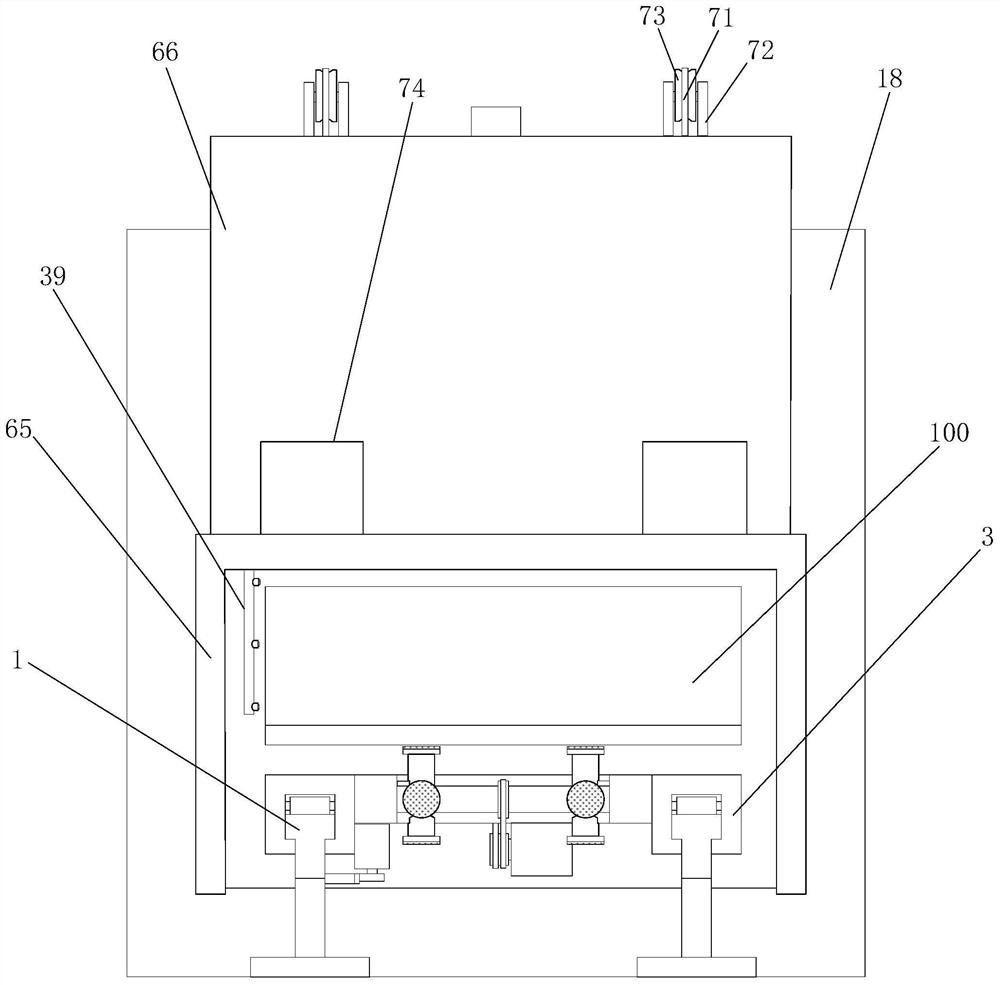

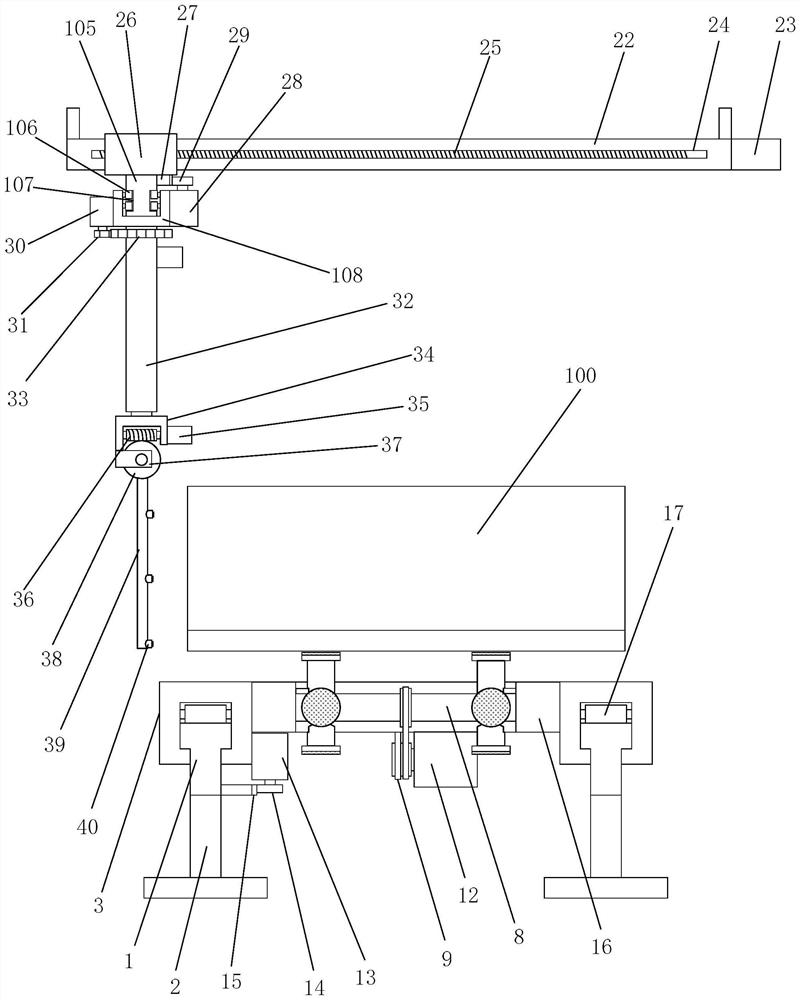

[0024] Such as Figure 1-5 As shown, the three-dimensional spraying system for large workpieces disclosed by the present invention includes: a rail conveying device and a three-dimensional painting device; the rail conveying device includes two support rails 1, a translation drive mechanism and a workpiece support mechanism; Shell 18, suspended paint spraying mechanism, entry and exit closure mechanism and paint mist purification mechanism; the entry and exit closure mechanism includes a closure drive unit and two window closure units;

[0025] On the left and right sides of the spray booth shell 18, a rail entry and exit window is arranged, and the support rail 1 runs through two rail entry and exit windows horizontally; the closed drive unit is installed on the top of the spray booth shell 18, and the two window sealing units are respectively installed in the spray booth On the left and right ends of the casing 18, the two window closing units are synchronously driven by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com