Method for extracting gas from separation layer below overlying strata, draining water and grouting through combined drill hole

A technology of layer separation and layer separation, which is used in gas discharge, drainage, earthwork drilling, etc., can solve the problems of easy collapse of drilling holes, high cost, and large workload, so as to reduce the amount of drilling engineering and save prevention and control costs. , the effect of saving engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0024] The method of the present invention utilizing composite drilling to extract gas from the separation layer under the overlying rock and drainage and grouting, the specific steps are as follows:

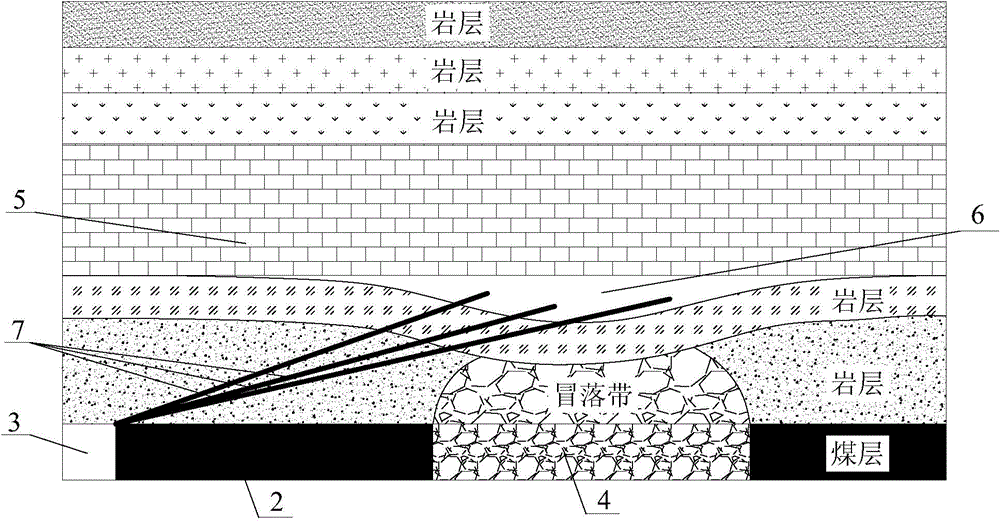

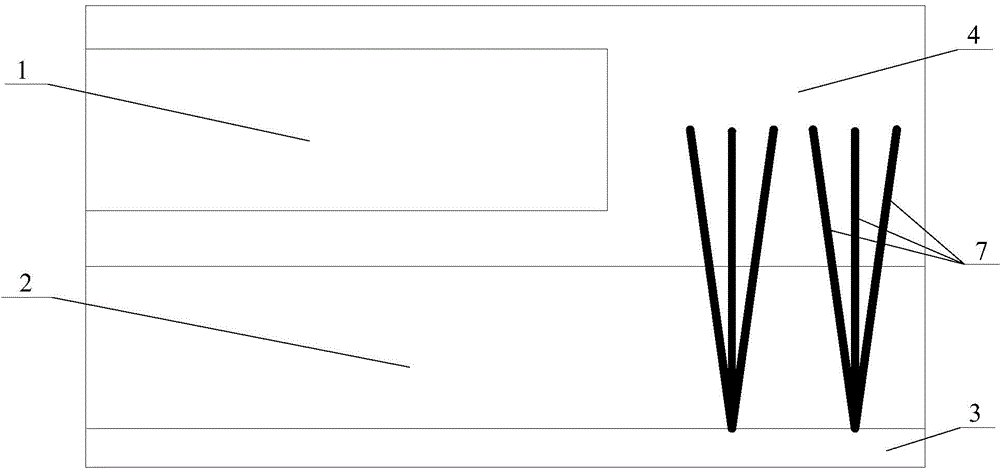

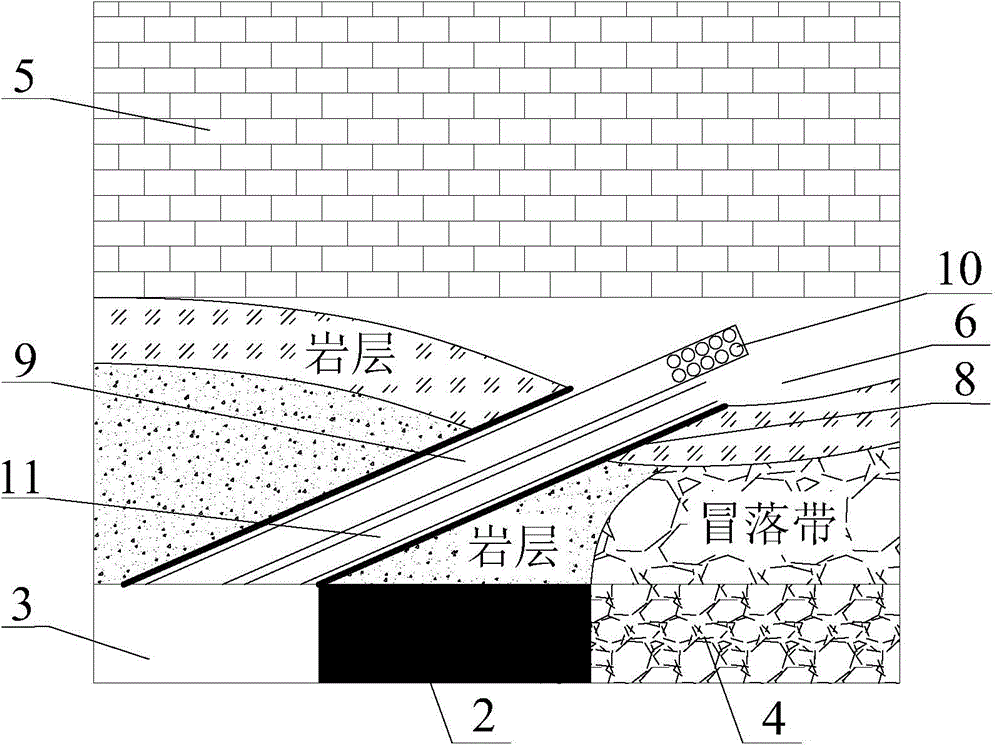

[0025] a. Set up a drilling field in the transportation lane 3 of the preparation working face 2 adjacent to the recovery working face 1, set up a drilling field every 30m, and advance to the top of the goaf 4 of the mining working face 1 in each drilling field At the position where the separation layer 6 is about to be formed under the overlying rock 5, multiple composite boreholes 7 are constructed to avoid the caving zone, image 3 There are 3 compound boreholes 7 for each drilling field shown in , which can be determined according to actual needs. The distance between the final holes of the plurality of composite boreholes 7 in the separation layer 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com