Gas control method for triple-purpose use of drilled holes in coal floor of close distance seam group

A technology for bottom-draining tunnels and coal seams, which is used in gas discharge, earth-moving drilling, safety devices, etc., can solve the problems of increased workload, single drilling function and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

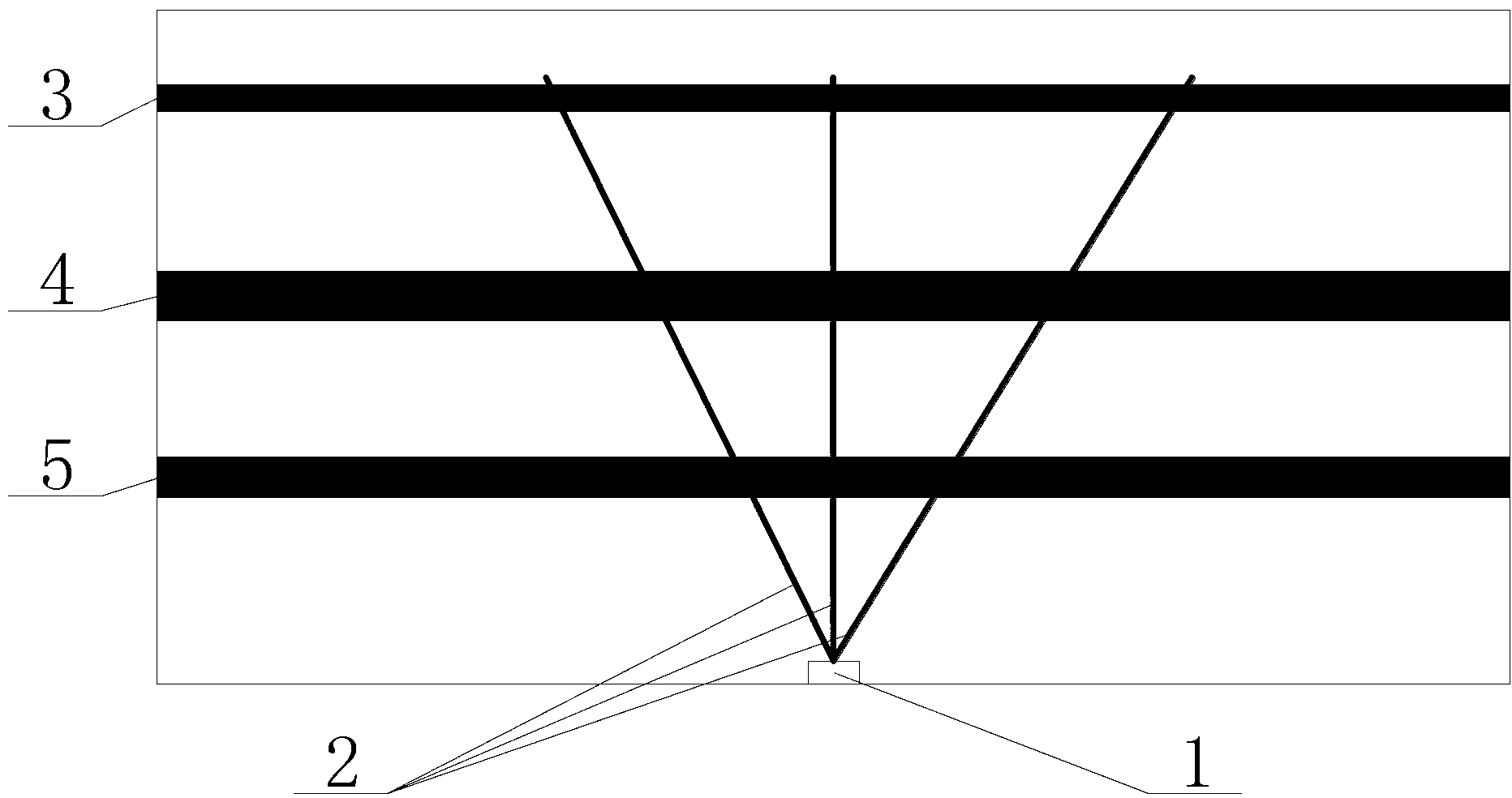

[0021] Embodiment 1: the specific method for the close-range coal seam group that comprises three coal seams is: a drilling site is set every 30m in the bottom pumping roadway 1, and each 15m area before and after the upper coal seam 3 is densely drilled through the bed 2, drilled The holes 2 pass through the middle coal seam 4 and the lower coal seam 5, and the distance between the final holes in the upper coal seam 3 is 5m×5m. The azimuth and inclination of the drilling can be determined by the position of the drilling site and the position of the final hole, so as to carry out construction. Steel casing 6 protection will be used in the whole process during construction drilling 2, and sieve holes 7 will be marked on the part where steel casing 6 passes through the coal seam.

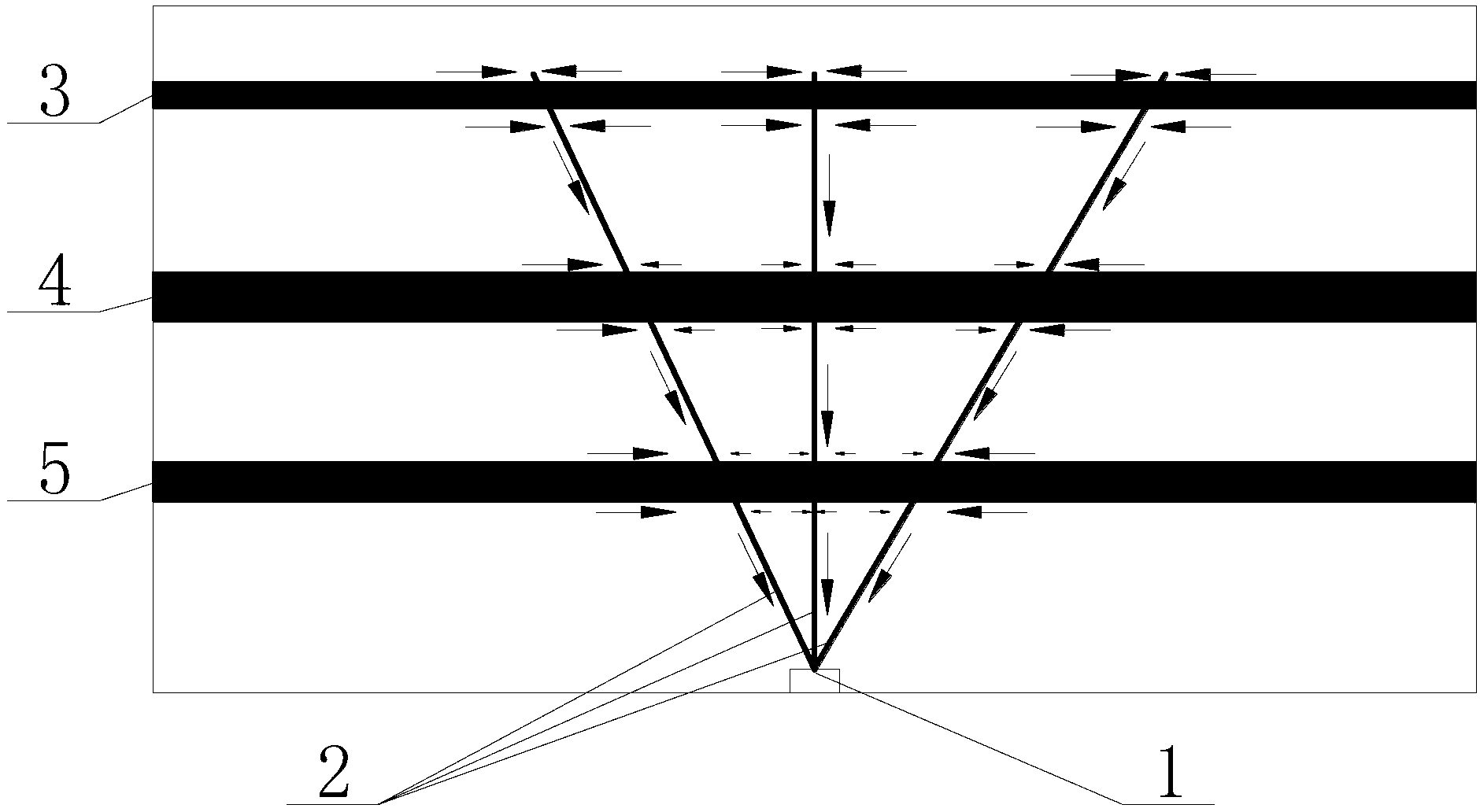

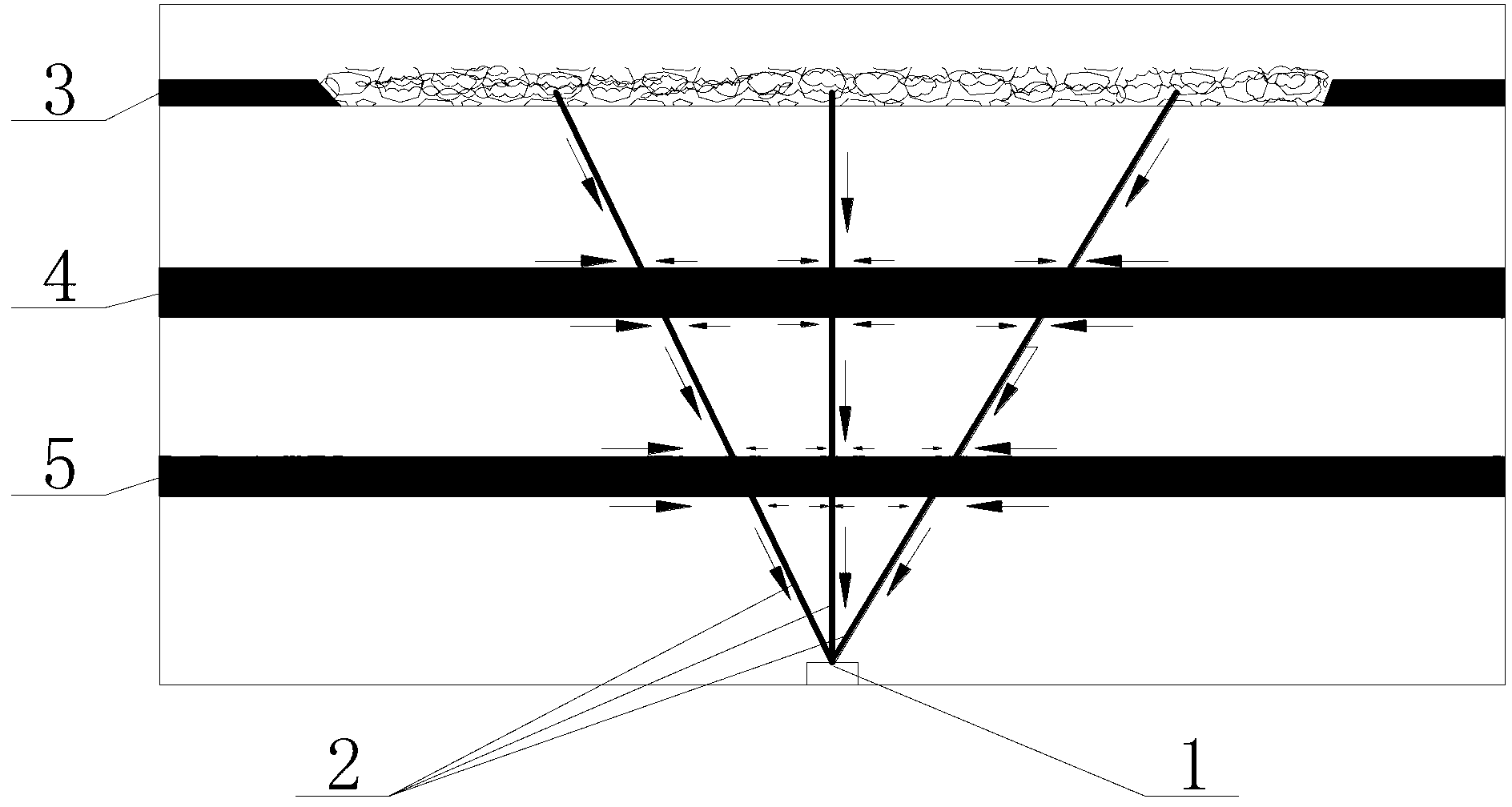

[0022] In the specific implementation, the gas drainage is carried out in the following stages by using the borehole 2 in the same drilling site:

[0023] The first stage: before the coal seam is min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com