Gas control method for drilling one hole and three purposes in the bottom pumping roadway of close-distance coal seam group

A technology for bottom-draining tunnels and coal seams, which is used in gas discharge, earth-moving drilling, safety devices, etc., can solve the problems of increased workload, single drilling function and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

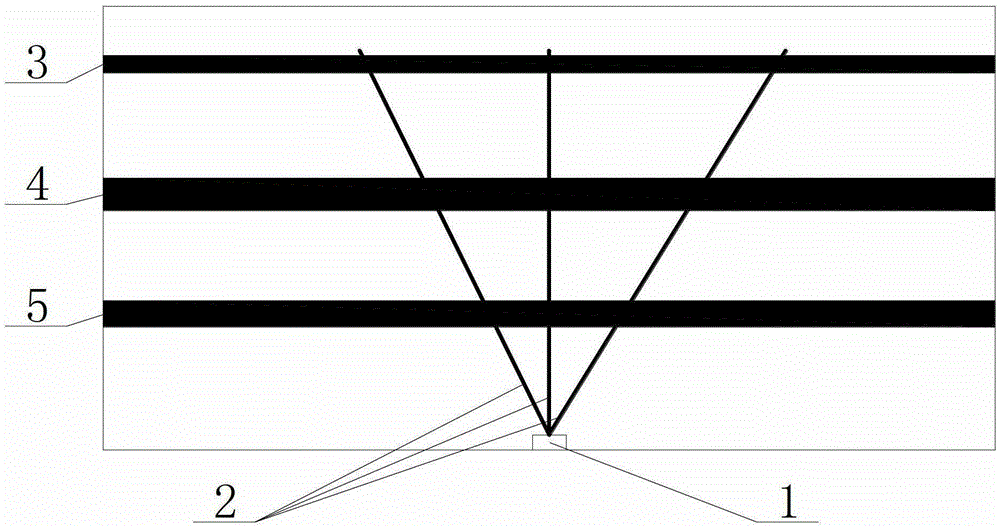

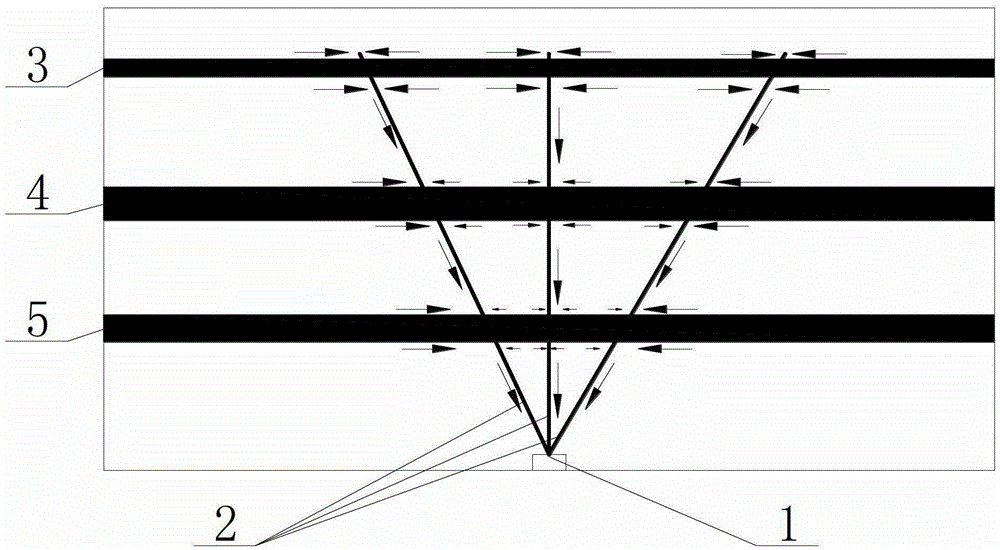

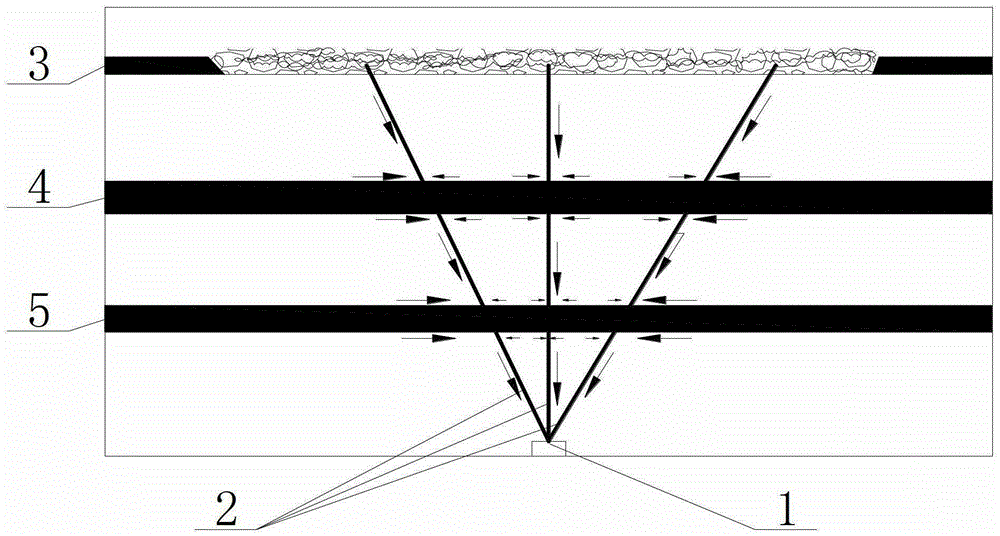

[0021] Example 1: The specific method for a short-distance coal seam group containing three coal seams is: set up a drill field every 30m in the bottom-draining roadway 1, construct intensive penetration boreholes 2 for each 15m area before and after the upper coal seam 3. The holes 2 pass through the middle coal seam 4 and the lower coal seam 5, and the final hole spacing in the upper coal seam 3 is 5m×5m. The azimuth and inclination of the borehole can be determined by the location of the drilling site and the location of the final hole for construction. The steel casing 6 shall be used for protection during the construction of the borehole 2, and a screen hole 7 shall be punched in the part where the steel casing 6 passes through the coal seam.

[0022] In the specific implementation, the borehole 2 in the same drilling field is used for gas drainage in the following stages:

[0023] The first stage: Before the coal seam is mined, the gas in the coal seam is pre-drained through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com