Projecting coal bed edge top drill construction technique and method for eliminating pumping blind zone

A technology of outburst coal seam and construction technology, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the difficulty of drilling deep holes in outburst coal seams, and the difficulty of eliminating blank areas in coal mining face, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

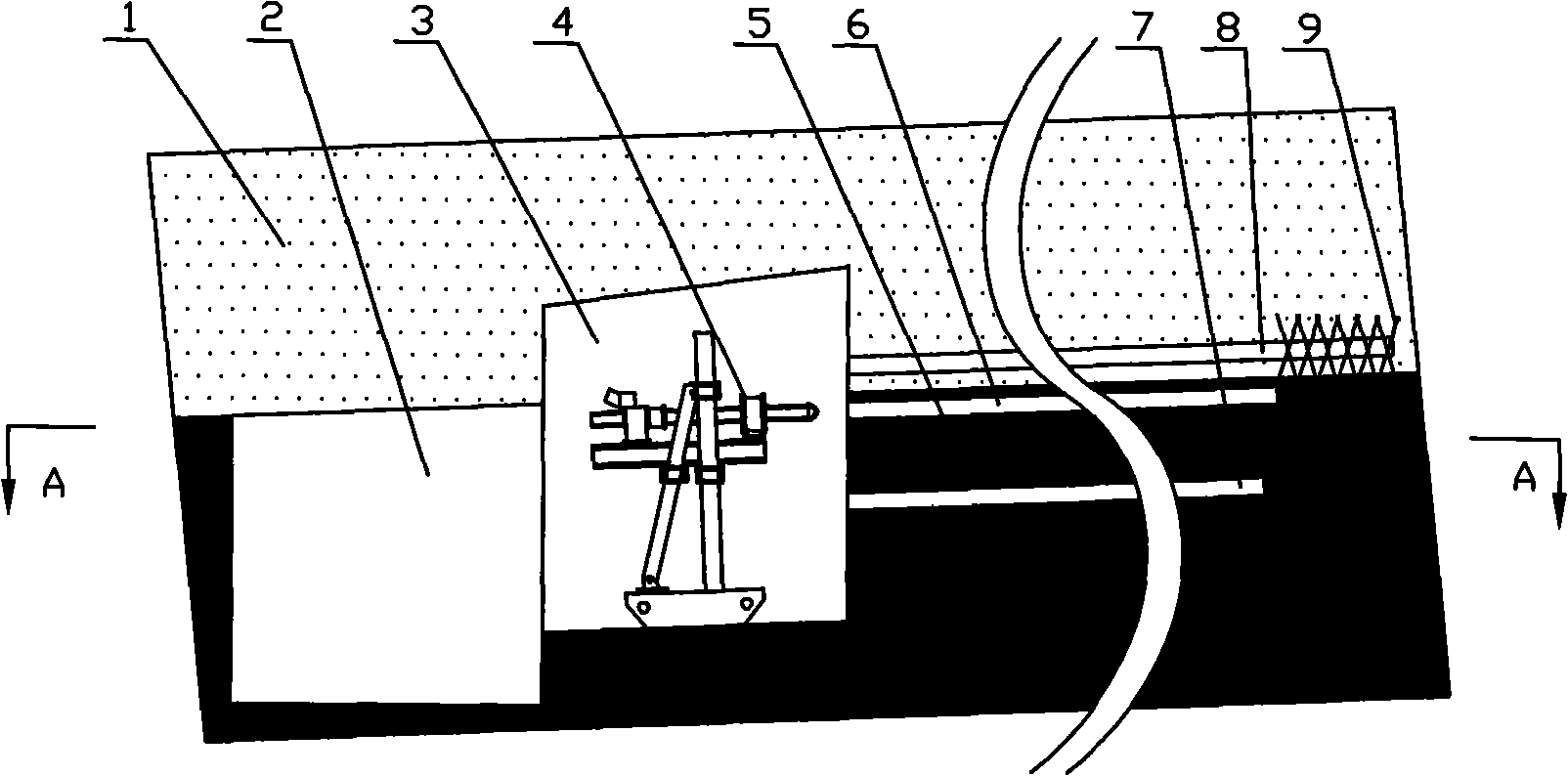

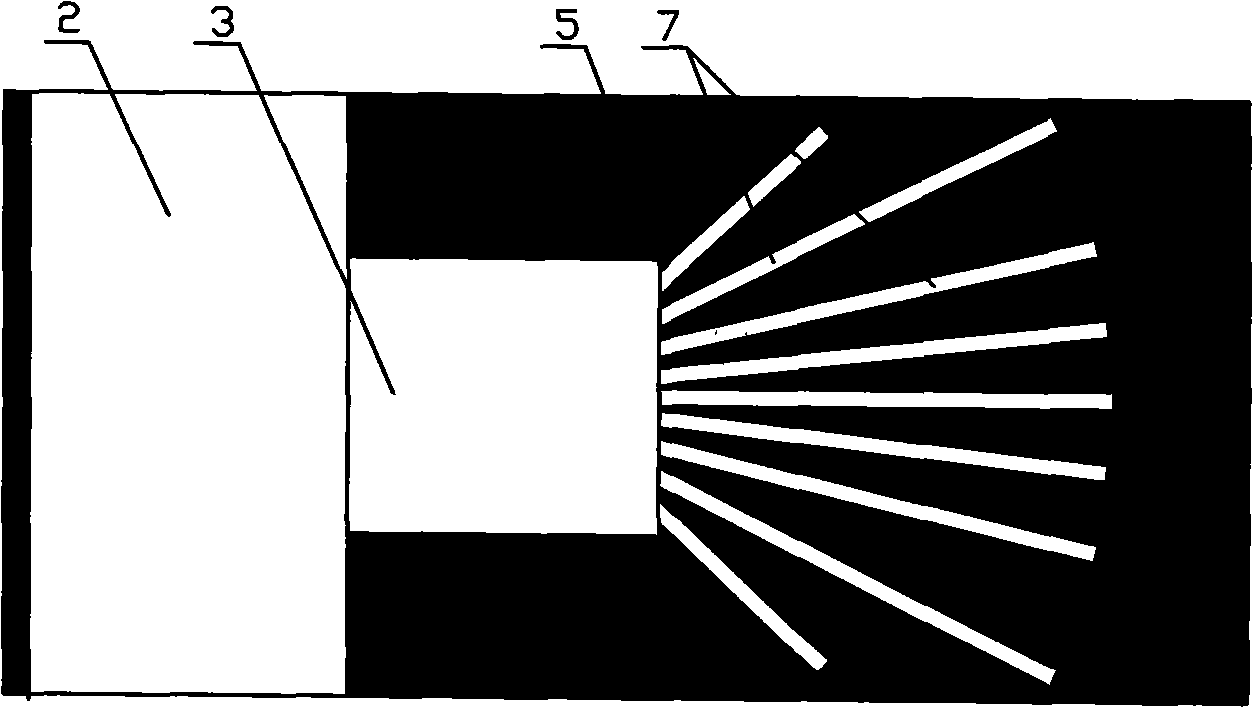

[0014] Such as figure 1 , 2 Shown, the present invention carries out by following steps operation:

[0015] The first step is to construct the top drilling field 3 in the roadside of the mining roadway 2. In the second step, the drilling rig 4 is placed in the top drilling site 3, and the height of the drilling rig 4 is adjusted so that the drilling rig 4 can construct the top coal hole 6 in the outburst coal seam 5. The third step is to construct a group of top-coal holes 6 in the roof-top drilling site 3. The top-coal holes 6 of this group are arranged in a divergent shape. Or pseudo-dip coincidence. The fourth step is to raise the height of the drilling rig, and construct the top rock hole 8 above the coal hole that fails to reach or pass through the blind area of drainage, so that the top rock hole 8 reaches or passes through the top of the blind area of extraction, and the top rock hole 8 The distance from the coal seam is determined according to the rock formatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com