Method for preventing gas from being accumulated at corners on coal faces

A technology for coal mining face and gas extraction, which is applied in the fields of gas discharge, mining equipment, earth-moving drilling, etc., can solve the problems of small improvement, air leakage, and gas concentration exceeding the limit in gas drainage lanes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

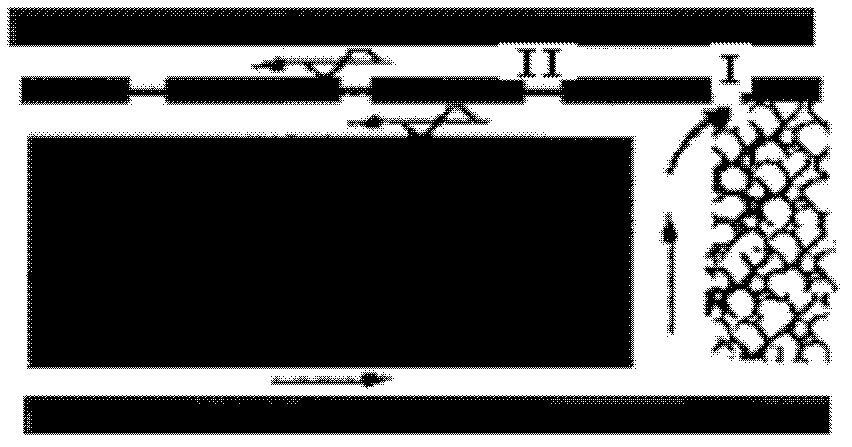

[0019] Such as Figure 5 , Image 6 As shown, the present invention is on the basis of the original "U" type recovery roadway, and arranges a process roadway along the top of the coal seam at an offset of 10-15m in the air return roadway of the coal mining face. According to different coal mining methods, the specific location of the process roadway is also different, which is accurately determined by numerical simulation method based on CFD (computational fluid dynamics) and seepage mechanics theory, combined with the porous medium characteristics of the working face and goaf. The process lane 1 is parallel to the air inlet lane 2 and the air return lane 3, such as Figure 7 As shown, the air inlet lane 2, the working face 4, and the process lane 1 form a "U"-shaped passage; at the same time, the air inlet lane 2, the working face 4, and the return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com